OLED displays dominate today’s flagship smartphones, delivering breathtaking contrast, ultra-high brightness beyond 3,000 nits, and razor-thin designs. Yet one persistent question continues to concern tech enthusiasts worldwide: is burn-in still a real problem in 2026?

Behind the scenes, the answer involves blue pixel chemistry, tandem stack architectures, deuterium-enhanced materials, and AI-driven pixel calibration systems embedded in Android 17 and iOS 19/20. Manufacturers are not relying on a single fix, but combining material science breakthroughs with intelligent software control to dramatically extend panel lifespan.

In this article, you will explore the physical mechanisms behind OLED degradation, the rise of Blue PHOLED and tandem OLED in devices like the Galaxy S26 Ultra and iPhone 17 Pro Max, long-term test data from RTINGS, and what next-generation technologies such as QDEL and MicroLED mean for the future of self-emissive displays. If you care about display longevity as much as peak brightness, this deep dive will give you the clarity you are looking for.

- Why OLED Burn-In Still Matters in 2026

- The Physics Behind Burn-In: Organic Degradation and the Blue Pixel Problem

- Blue PHOLED Breakthrough: LG Display’s Commercial Verification and What It Changes

- Tandem OLED Architecture: Doubling Emission Layers to Extend Lifespan

- Samsung’s M14 Material Set and Deuterium Technology Explained

- CoE (Color Filter on Encapsulation) and Pol-less Design: Efficiency Gains Beyond Brightness

- AI-Driven Burn-In Prevention in Android 17: Adaptive Dimming and Display Health APIs

- iOS 19/20 Pixel-Level Calibration and Invisible Pixel Shifting

- Flagship Showdown: iPhone 17 Pro Max vs Galaxy S26 Ultra vs Pixel 10 Pro XL vs Xperia 1 VII

- What Long-Term RTINGS Burn-In Tests Reveal About Modern OLED Panels

- Practical Burn-In Prevention: Settings and Usage Habits That Actually Work

- Warranty and Protection Programs: AppleCare+, Samsung Care+, and Pixel Care+

- Beyond OLED: QDEL, MicroLED, and the Race Toward Burn-In-Free Displays

- 参考文献

Why OLED Burn-In Still Matters in 2026

OLED has become the default display technology for flagship and upper mid-range smartphones, thanks to its perfect blacks, infinite contrast, and ultra-thin form factor. Yet even in 2026, burn-in remains a relevant topic for enthusiasts and heavy users. The reason is simple: burn-in is not a software bug but a materials science issue rooted in organic degradation.

Unlike LCDs, OLED pixels emit their own light. Each subpixel ages depending on how hard and how long it is driven. When certain UI elements such as status bars, navigation indicators, or game HUDs stay static for extended periods, those pixels degrade faster, leading to uneven luminance and permanent image retention.

According to research published by the American Chemical Society on OLED stability, blue emitters are particularly vulnerable because they require higher photon energy and experience greater thermodynamic stress. This imbalance at the material level is why burn-in risk can never be reduced to zero as long as organic compounds are used.

| Subpixel Color | Energy Requirement | Relative Degradation Speed |

|---|---|---|

| Red | Lower | Slower |

| Green | Moderate | Stable (Phosphorescent) |

| Blue | Highest | Fastest |

Commercial red and green phosphorescent materials can achieve near 100% internal quantum efficiency and lifetimes exceeding 100,000 hours at moderate brightness. Blue materials, historically limited to fluorescent efficiency around 25%, have required higher current density, accelerating heat generation and chemical breakdown. Even with 2025–2026 breakthroughs in blue phosphorescent validation, the long-term balance between efficiency and stability is still being optimized.

Independent long-term testing reinforces why this matters. RTINGS, known for its accelerated longevity tests, has reported that older OLED panels developed visible burn-in after roughly 8,850 hours of extreme static content exposure. Newer 2024–2025 panels showed dramatic improvement, with over 14,000 hours before significant permanent artifacts appeared. However, brightness reduction of 20–50% over very long usage cycles was still observed.

This does not mean modern smartphones are fragile. In fact, typical consumer usage patterns and a 3–4 year replacement cycle mean most users will never encounter severe burn-in. But power users—those running navigation apps for hours, crypto dashboards, or always-on trading charts—create conditions closer to laboratory stress tests than average daily scrolling.

Another reason burn-in still matters in 2026 is peak brightness. Flagship smartphones now reach 2,800 to over 3,000 nits in HDR highlights. Higher luminance requires higher current, and higher current increases thermal stress. As manufacturers push brightness for outdoor visibility, they must simultaneously invest in materials like deuterated hosts and tandem stack structures to distribute load more evenly.

There is also a perception gap. Many consumers assume software features like pixel shifting or AI dimming have “solved” burn-in completely. In reality, these systems mitigate uneven wear rather than eliminate it. The underlying chemistry still follows cumulative degradation models described in academic OLED lifetime research.

For enthusiasts who keep devices longer, resell phones, or demand consistent color accuracy for content creation, even subtle luminance drift can matter. A slightly warmer status bar area or reduced peak brightness after years of heavy use may not ruin usability, but it affects display uniformity.

In short, burn-in remains relevant in 2026 because OLED is still an organic technology operating under physical constraints. Improvements are real and substantial, but as long as pixels age based on usage, uneven aging remains a possibility. Understanding that balance between innovation and physics is essential for anyone deeply invested in display performance.

The Physics Behind Burn-In: Organic Degradation and the Blue Pixel Problem

OLED burn-in is not a software glitch or a temporary image retention artifact. It is a materials science problem rooted in irreversible organic degradation inside each emissive pixel. Because OLED is a self-emissive technology, every subpixel ages according to how hard it is driven, and uneven aging is what ultimately becomes visible as permanent ghosting.

At the core of this phenomenon are organic emissive layers composed of small molecules or polymers that emit light when excited by electrical current. Over time, high-energy excitons and heat trigger chemical bond breakage, molecular rearrangement, and the formation of non-radiative recombination centers. According to research published by the American Chemical Society on OLED stability, these degradation pathways directly reduce luminous efficiency and alter emission spectra.

The mechanism is cumulative and load-dependent. A navigation bar, status icon, or news ticker that remains static forces specific subpixels to operate at higher average current density. As a result, those pixels experience accelerated chemical aging compared with surrounding areas, leading to measurable luminance loss.

The issue becomes particularly critical when we examine the blue subpixel. Among red, green, and blue emitters, blue requires the highest photon energy due to its shorter wavelength. That higher energy translates into greater thermodynamic stress and a higher probability of molecular instability.

Industry and academic analyses consistently refer to this as the “blue pixel problem.” While red and green phosphorescent emitters have achieved internal quantum efficiencies approaching 100% and operational lifetimes exceeding 100,000 hours at 1,000 nits under laboratory conditions, blue materials have historically relied on less efficient fluorescent systems. With typical internal efficiencies around 25%, they require higher current to achieve comparable brightness, accelerating degradation.

| Subpixel Color | Typical Emission Energy | Relative Stability |

|---|---|---|

| Red | Lower photon energy | High stability, long lifetime |

| Green | Moderate photon energy | Very high stability with phosphorescence |

| Blue | Highest photon energy | Lower stability, faster degradation |

This imbalance has system-level consequences. As blue subpixels degrade faster, the display gradually shifts in color balance, often becoming warmer over time. Compensation circuits can partially correct luminance drift, but they cannot reverse chemical decomposition inside the emissive layer.

Accelerated lifetime testing provides empirical evidence of this behavior. Large-scale endurance experiments reported by RTINGS show that after thousands of hours of high-brightness static content, measurable peak luminance reduction occurs, sometimes in the range of 20–50% depending on usage conditions. Although modern panels manage this more effectively than earlier generations, the underlying physics remain unchanged.

From a microscopic perspective, degradation often follows a power-law or stretched exponential decay model. As described in published OLED degradation modeling studies, luminance L(t) decreases as defect states accumulate within the organic layer. These defects act as quenching sites, converting electrical energy into heat rather than photons.

Thermal effects amplify the process. Blue emitters operating at high current density generate more localized heating, which in turn accelerates bond dissociation and molecular diffusion. This feedback loop explains why static high-brightness elements—such as HDR highlights or always-on indicators—pose disproportionate stress on specific regions of the panel.

Burn-in, therefore, is not a sudden failure but a differential aging phenomenon driven by energy intensity, time, and material limitations. Even with perfect manufacturing uniformity, uneven usage alone can create visible artifacts over long periods.

Importantly, modern OLED stacks distribute emission across multiple layers to reduce per-layer stress, but the blue channel still defines the practical lifetime ceiling. As OLED-Info and related market analyses emphasize, the stability of blue materials continues to be the bottleneck for overall device longevity and efficiency.

For technology enthusiasts, understanding this physics reframes burn-in from a mysterious defect to a predictable outcome of organic semiconductor behavior. The challenge is not whether degradation occurs, but how slowly and how uniformly it can be managed.

As long as displays rely on organic emitters that convert electrical energy into high-energy blue photons, the blue pixel will remain the most vulnerable link in the chain. Every mitigation strategy—whether material innovation or intelligent driving control—ultimately exists to counteract this fundamental physical reality.

Blue PHOLED Breakthrough: LG Display’s Commercial Verification and What It Changes

In May 2025, LG Display announced that it had become the world’s first company to verify the commercialization of blue phosphorescent OLED panels on a mass-production line. According to the company’s official release and coverage by industry outlets such as TFTCentral, this milestone was achieved in collaboration with Universal Display Corporation (UDC), long known for its high-efficiency phosphorescent emitters.

This development is not a mere laboratory success. It represents a transition from prototype-level blue PHOLED performance to commercial-grade validation, meaning the material stack has met the stability, efficiency, and yield requirements necessary for real-world manufacturing.

For the first time, the industry’s “blue problem” is being addressed at a production-ready level rather than as a research promise.

| Item | Conventional Blue (Fluorescent) | LG Hybrid Blue PHOLED |

|---|---|---|

| Emission Mechanism | Fluorescent | Hybrid (Fluorescent + Phosphorescent) |

| Internal Efficiency | ~25% theoretical limit | Significantly improved via phosphorescence |

| Power Consumption | Higher current required | Approx. 15% reduction |

| Commercial Status | Widely used | Commercial line verified (2025) |

The technical core lies in a hybrid two-stack structure. LG Display applies a blue fluorescent layer in one stack and a blue phosphorescent layer in another, combining the long-term stability of fluorescence with the high internal quantum efficiency of phosphorescence. As reported in the company’s announcement, this approach achieved around a 15% reduction in power consumption while maintaining comparable stability to existing panels.

This efficiency gain directly impacts burn-in dynamics. Blue pixels historically degrade faster because they require higher photon energy and greater current density, a challenge extensively documented in research published by the American Chemical Society. Lowering the required driving current reduces thermal stress and slows the irreversible chemical degradation of organic compounds.

Commercial verification changes the competitive landscape because it shifts blue PHOLED from “future roadmap” to “immediate differentiation factor.”

For device makers, this means new design trade-offs become possible. A 15% power saving can be reinvested into higher peak brightness, extended panel lifespan, or reduced thermal load within slim smartphone chassis. In ultra-bright HDR scenarios exceeding 2,500–3,000 nits, even incremental efficiency improvements materially affect heat generation and long-term uniformity.

Importantly, verification on a commercial line signals acceptable yield and manufacturability. In OLED production, material innovation is meaningless without process compatibility. By confirming that blue PHOLED can operate within existing evaporation and stack architectures, LG Display lowers the barrier for broader ecosystem adoption.

The breakthrough does not imply that burn-in disappears. However, it meaningfully narrows the historical performance gap between blue and red/green phosphorescent emitters. In practical terms, it moves the industry closer to the long-envisioned “all-phosphorescent” OLED structure, long described as the final step toward maximum efficiency.

For enthusiasts tracking display evolution, this moment marks a structural turning point. The blue bottleneck has constrained OLED for over a decade. With commercial verification now achieved, blue PHOLED becomes not just a scientific achievement, but a strategic lever that reshapes how next-generation OLED panels balance brightness, longevity, and energy efficiency.

Tandem OLED Architecture: Doubling Emission Layers to Extend Lifespan

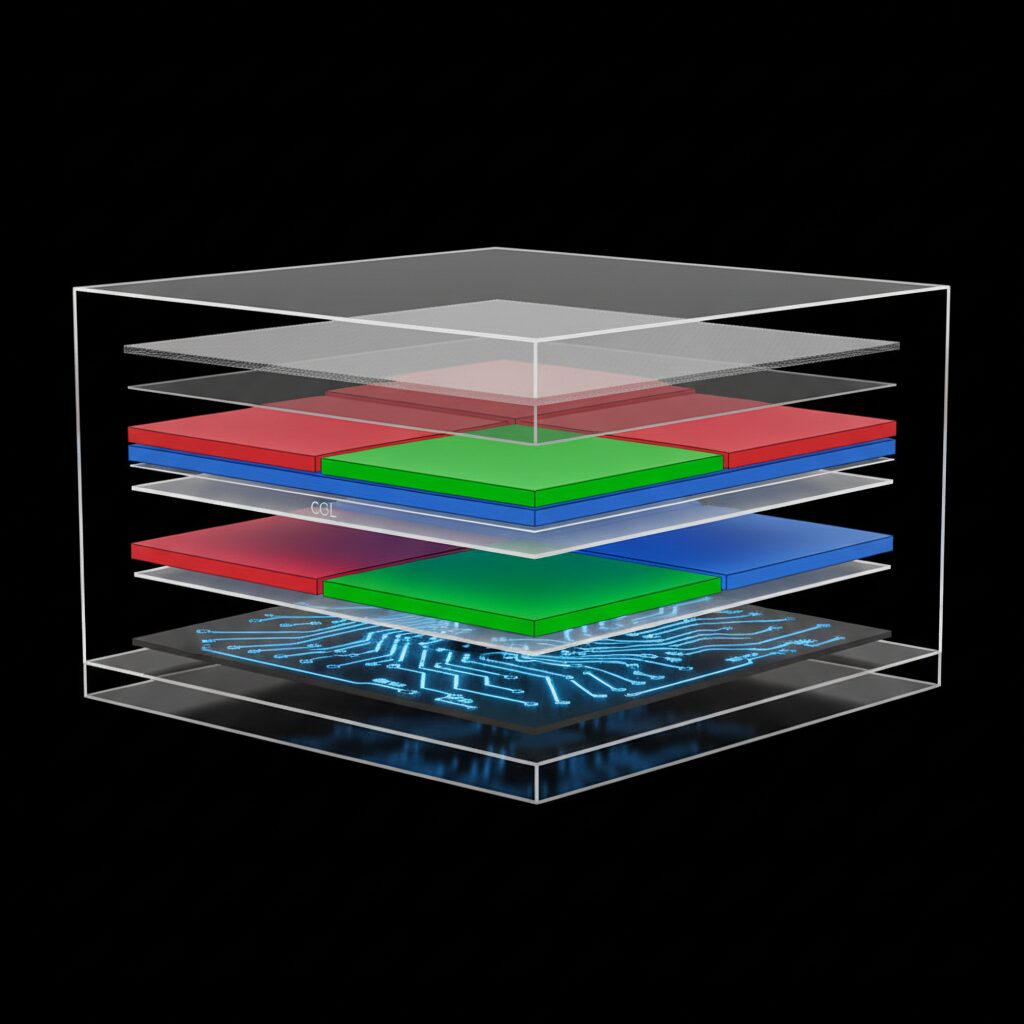

Tandem OLED architecture has emerged as one of the most decisive hardware solutions to burn-in in 2026. Instead of relying on a single RGB emission stack, manufacturers layer two complete emission units on top of each other, effectively creating a dual light-generating structure within one pixel.

By doubling the emission layers, the required current per layer is significantly reduced while maintaining the same overall brightness. This lower electrical stress directly slows the chemical degradation of organic materials, especially the vulnerable blue emitters highlighted in research published by ACS on OLED stability.

The structural differences are substantial and have measurable implications for lifespan and efficiency.

| Structure | Emission Layers | Theoretical Lifespan | Relative Efficiency |

|---|---|---|---|

| Single-Stack OLED | 1× RGB | Baseline (1.0x) | Standard |

| Tandem OLED | 2× RGB (stacked) | Up to 4.0x | Up to 2× |

Because each stack shares the luminance load, peak brightness can be achieved with roughly half the current per layer. According to industry analyses cited by OLED-Info and Omdia, this configuration not only improves luminous efficiency but can theoretically extend panel lifetime by up to four times under comparable operating conditions.

This matters most for blue subpixels. As established in multiple degradation models, blue materials deteriorate faster due to higher photon energy requirements. In a tandem setup, the stress distribution mitigates this imbalance, reducing differential aging between RGB elements and lowering the risk of visible image retention.

Real-world durability data reinforces this logic. RTINGS’ long-term accelerated tests show that modern OLED panels sustain over 14,000 hours of high-brightness stress with far less permanent burn-in than earlier generations. While those tests are not exclusively smartphone-focused, the same current-density principle applies, and tandem structures further reduce per-layer strain.

There are trade-offs. Tandem fabrication requires additional deposition steps and increased use of fine metal masks, raising production costs by an estimated 50–75% compared to single-stack designs. However, for flagship smartphones pushing 3,000 nits HDR brightness, the architecture enables high luminance without proportionally accelerating material fatigue.

In practical terms, tandem OLED transforms brightness from a longevity liability into a manageable engineering variable. For power users who demand sustained HDR performance, gaming, and always-on features, this dual-stack strategy is a foundational shift that directly addresses the physics behind burn-in rather than merely masking its symptoms.

Samsung’s M14 Material Set and Deuterium Technology Explained

Samsung Display’s latest M14 material set represents a fundamental shift in how OLED longevity and efficiency are engineered at the molecular level. Rather than relying solely on structural changes such as tandem stacking, M14 focuses on strengthening the organic materials themselves, especially through the expanded use of deuterium technology across host layers.

To understand why this matters, it is important to recall that OLED degradation is largely driven by bond breakage under electrical and thermal stress. According to research published in ACS journals on blue emitter instability, high-energy excitation accelerates chemical decomposition inside the emissive layer. Samsung’s approach with M14 directly targets this vulnerability.

Deuterium is a heavier isotope of hydrogen, and when substituted into organic compounds, it forms stronger chemical bonds. These stronger carbon–deuterium bonds are more resistant to thermal and electrical stress than conventional carbon–hydrogen bonds, slowing the molecular degradation that leads to luminance loss and burn-in.

| Technology Element | Key Effect | Impact on OLED Panel |

|---|---|---|

| Deuterated Host Materials | Stronger atomic bonds | Improved thermal stability |

| Optimized Energy Transfer | Higher emission efficiency | Lower required drive current |

| Full-stack Material Tuning | Balanced RGB aging | Reduced differential burn-in |

Industry reports cited by SamMobile and other supply chain watchers indicate that M14 achieves approximately 20–30% improved power efficiency compared with previous-generation material sets. Lower power consumption directly translates into reduced heat generation, which is one of the primary accelerants of organic layer degradation.

Even more compelling is the reported lifespan improvement of roughly 50% under comparable brightness conditions. In practical terms, that means pixels can sustain high luminance output for significantly longer before measurable decay occurs. For users who frequently operate their devices outdoors at 2,500–3,000 nits peak brightness, this resilience is critical.

Another crucial aspect of M14 is its application across all color host layers rather than selectively reinforcing only blue. Because burn-in often appears as uneven aging between RGB subpixels, balanced material durability helps maintain chromatic accuracy over time. This systems-level optimization reduces the risk of visible image retention in UI-heavy usage scenarios.

From a materials science perspective, deuteration does not alter the visual characteristics of the display. Instead, it enhances bond dissociation energy, making the emissive stack more resistant to exciton-induced damage. As OLED-Info and other industry analysts note, incremental molecular improvements can compound dramatically at scale, especially across billions of subpixels.

M14 therefore represents a shift from reactive mitigation to proactive durability engineering. Rather than correcting pixel degradation through software alone, Samsung is reinforcing the atomic structure of the panel itself.

For gadget enthusiasts who track display evolution closely, M14 is more than a generational label. It signals how the OLED arms race in 2026 is being fought not just in brightness numbers, but deep within the chemistry of the panel—where longevity, efficiency, and burn-in resistance are ultimately decided.

CoE (Color Filter on Encapsulation) and Pol-less Design: Efficiency Gains Beyond Brightness

CoE (Color Filter on Encapsulation) and Pol-less design represent a structural shift in OLED architecture, focusing not only on peak brightness but on how efficiently light is generated, transmitted, and preserved over time.

Traditional OLED stacks rely on a circular polarizer to suppress ambient reflections. While effective, polarizers inevitably absorb a portion of emitted light, forcing pixels to operate at higher current to achieve target luminance.

By removing the polarizer and integrating the color filter directly on the encapsulation layer, CoE reduces optical loss at the source. This translates into lower driving current for the same perceived brightness, which directly mitigates thermal stress and long-term degradation.

| Architecture | Light Transmission | Impact on Power | Burn-in Implication |

|---|---|---|---|

| Conventional OLED + Polarizer | Partial light absorption | Higher current required | Increased thermal load |

| CoE + Pol-less | Improved light extraction | Lower current for same nits | Reduced cumulative stress |

According to industry reports covering Samsung Display’s M14 generation panels, the combination of CoE and deuterated material sets improves overall power efficiency by roughly 20–30% compared with earlier stacks. This gain is not merely a battery-life story. Lower electrical load slows the chemical degradation of organic emitters, particularly the blue subpixels known to be most vulnerable, as discussed in studies published by ACS on OLED stability.

Another critical dimension is reflectance control. CoE integrates a Black Pixel Define Layer (PDL), which suppresses internal reflections and enhances contrast under strong ambient light. Instead of overpowering sunlight with brute-force luminance, the panel maintains readability through optical efficiency.

This means devices can sustain 2,600–3,200 nits peak HDR performance without proportionally increasing long-term wear. The efficiency gain is systemic rather than cosmetic.

Pol-less construction also contributes to mechanical and thermal advantages. Removing the polarizer reduces panel thickness, allowing manufacturers to reallocate internal volume to heat dissipation structures or larger batteries. Better thermal management stabilizes junction temperatures, and as accelerated degradation models suggest, even small temperature reductions significantly extend emitter lifetime.

In practical usage scenarios—navigation bars, always-on indicators, static UI elements—the reduced current density lowers cumulative differential aging between frequently lit and rarely lit pixels. Over a three- to four-year ownership cycle, this can meaningfully narrow luminance variance across the panel.

For enthusiasts evaluating display technology beyond headline brightness numbers, CoE and Pol-less design represent a shift toward optical discipline. Instead of pushing pixels harder, manufacturers are extracting more usable light per electron.

The real efficiency gain lies not in making OLED brighter, but in making brightness cheaper in electrical and chemical terms. That distinction is central to extending panel longevity in 2026-era flagship smartphones.

AI-Driven Burn-In Prevention in Android 17: Adaptive Dimming and Display Health APIs

Android 17 marks a structural shift in how the OS approaches OLED longevity. Rather than relying solely on static safeguards such as screen timeout or global brightness caps, it introduces AI-driven, real-time burn-in mitigation that operates at the content and pixel-behavior level.

This evolution reflects a broader industry consensus: hardware improvements like tandem OLED and deuterated materials extend lifespan, but software intelligence is essential to manage uneven pixel wear in daily use.

Core Burn-In Protection Features in Android 17

| Feature | Function | Burn-In Impact |

|---|---|---|

| Display Health Tracking API | Monitors cumulative panel usage data | Quantifies aging trends over time |

| Adaptive Content Dimming | AI adjusts luminance of static UI elements | Reduces localized pixel stress |

| Enhanced Blur Effects | Dynamic transparency in system UI | Distributes pixel load more evenly |

The new Display Health Tracking API is particularly significant. Similar to battery health metrics, it allows the system to evaluate cumulative brightness exposure and usage patterns. According to coverage from Nokiapoweruser, Android 17 is designed to expose panel health data at the system level, opening the door for manufacturers to visualize degradation trends or adjust calibration dynamically.

This approach aligns with findings from accelerated aging research discussed in Patsnap’s OLED lifespan analysis, which show that uneven luminance load—not total usage alone—is a primary contributor to permanent image retention.

Adaptive Content Dimming represents the most visible innovation. Instead of dimming the entire display, Android 17’s AI analyzes on-screen composition in real time. Static regions such as status bars, navigation hints, or persistent widgets are subtly reduced in brightness at a level below human perceptual thresholds. The result is lower electrical stress on vulnerable subpixels—especially blue emitters—without altering the user experience.

Material 3 Expressive’s expanded blur and transparency layers further reinforce this strategy. As reported by Sammy Fans, Android 17 adopts a more nuanced blur implementation compared with earlier UI generations. By continuously varying pixel states rather than locking them into fixed high-contrast blocks, the system minimizes long-duration static color exposure.

In practical terms, this means that even Always-On Display elements are less likely to age unevenly. Instead of a rigid white clock burning into the same coordinates, luminance distribution becomes fluid and context-aware.

For power users and developers, the introduction of display health APIs also signals a new layer of transparency. Device makers can fine-tune calibration tables over time, and future updates may adapt driving voltage curves based on real-world aging patterns.

As OLED peak brightness now exceeds 2,500–3,000 nits in flagship smartphones, intelligent dimming and health-aware management are no longer optional. Android 17 demonstrates that sustainable high luminance depends as much on software orchestration as on material science innovation.

iOS 19/20 Pixel-Level Calibration and Invisible Pixel Shifting

In iOS 19 and iOS 20, Apple has significantly refined its pixel-level calibration and invisible pixel shifting technologies to address OLED burn-in at a microscopic level.

Rather than relying solely on material improvements, the system continuously monitors how each individual pixel ages over time and compensates in real time.

This software-driven precision control has become a core pillar of Super Retina XDR durability.

How Pixel-Level Calibration Works

| Process | Purpose | Impact on Burn-in |

|---|---|---|

| Usage Tracking | Record cumulative luminance per pixel | Detect uneven aging patterns |

| Voltage Adjustment | Fine-tune driving voltage | Restore brightness uniformity |

| Periodic Recalibration | Run background correction cycles | Suppress visible image retention |

Since the introduction of OLED iPhones, Apple has implemented algorithms that log cumulative pixel usage and adjust electrical characteristics accordingly, as discussed by long-time OLED engineers in technical forums and user reports.

In iOS 19/20, this system has become more adaptive, leveraging on-device intelligence to predict which UI regions are at higher risk, such as status bars or navigation indicators.

Instead of applying uniform correction, the calibration engine selectively increases or decreases drive voltage at the subpixel level, preserving color accuracy while masking differential aging.

This approach directly addresses the physical degradation mechanism described in ACS publications, where blue subpixels degrade faster due to higher photon energy requirements.

By compensating luminance drift dynamically, the display maintains perceptual uniformity even after thousands of hours of cumulative use.

Users experience a screen that looks visually consistent long before any imbalance becomes noticeable.

Invisible Pixel Shifting in Always-On Display

Always-On Display (AOD) presents a unique challenge because static elements like clocks remain visible for extended periods.

To counter this, iOS 19/20 employs invisible pixel shifting that moves UI elements at subpixel intervals.

The displacement is small enough to remain imperceptible to the human eye but large enough to redistribute electrical stress across neighboring pixels.

On the latest Pro models, the shifting cycle is AI-optimized based on contextual awareness.

For example, when ambient light is low or the device is placed face down, AOD is automatically disabled to eliminate unnecessary emission, a practice widely recommended in OLED longevity discussions.

When active, the system subtly varies not only position but also luminance intensity within safe perceptual thresholds.

Accelerated longevity tests reported by RTINGS show that modern OLED panels primarily suffer gradual brightness reduction rather than catastrophic burn-in under typical usage.

Apple’s calibration and shifting strategy specifically targets this gradual drift, smoothing differences before they accumulate into visible artifacts.

The result is not the elimination of physical aging, but the intelligent concealment and balancing of it.

For power users who rely heavily on static productivity apps or persistent widgets, these background corrections operate continuously without manual intervention.

The system runs recalibration during idle states, ensuring no disruption to user experience.

This seamless integration of hardware sensing and software compensation defines Apple’s 2026-era approach to OLED preservation.

Flagship Showdown: iPhone 17 Pro Max vs Galaxy S26 Ultra vs Pixel 10 Pro XL vs Xperia 1 VII

The 2026 flagship race is no longer just about peak brightness or resolution. It is about how intelligently each brand balances extreme luminance with long-term OLED durability. The iPhone 17 Pro Max, Galaxy S26 Ultra, Pixel 10 Pro XL, and Xperia 1 VII all push past 2,500 nits in HDR, yet their philosophies toward burn-in mitigation differ significantly.

| Model | Peak HDR Brightness | Core Burn-in Strategy |

|---|---|---|

| iPhone 17 Pro Max | 3,000 nits | AI pixel calibration + advanced pixel shift |

| Galaxy S26 Ultra | 2,600–3,200 nits | M14 deuterated materials + CoE structure |

| Pixel 10 Pro XL | 2,800 nits | Android 17 display health tracking + service coverage |

| Xperia 1 VII | 2,500 nits | Strict brightness governance + image optimization |

Apple focuses on algorithmic precision. Since the iPhone X era, Apple has tracked cumulative pixel usage, and in iOS 19/20 this evolves into more granular pixel-level voltage calibration. By subtly adjusting drive voltage per pixel, luminance uniformity is preserved even as organic compounds age. According to long-term discussions among OLED engineers and teardown analyses, this tight hardware–software integration is one reason visible burn-in remains rare within a typical 3–4 year ownership cycle.

Samsung takes a materials-first approach with the Galaxy S26 Ultra. The M14 OLED stack applies deuterium to host materials across all colors. Because deuterium forms stronger atomic bonds than hydrogen, resistance to thermal and electrical stress improves measurably. Industry reporting indicates 20–30% power efficiency gains and up to 50% lifespan extension compared to earlier generations. Combined with CoE (Color filter on Encapsulation), which removes the traditional polarizer layer, light extraction improves while reducing unnecessary energy loss.

Google’s Pixel 10 Pro XL differentiates itself through ecosystem-backed durability. Android 17 introduces display health APIs and adaptive content dimming that dynamically reduce static UI stress. In parallel, Pixel Care+ explicitly includes screen issues in its coverage program, shifting part of the longevity conversation from pure hardware endurance to risk mitigation and after-sales confidence.

Sony’s Xperia 1 VII follows a more conservative philosophy. Rather than chasing the absolute highest luminance headline, Sony emphasizes calibrated brightness ceilings and BRAVIA-derived image processing. By avoiding excessive sustained peak output, thermal load is naturally moderated. Research published by the American Chemical Society on blue OLED degradation highlights how high-energy blue emitters accelerate aging; Sony’s restrained tuning indirectly addresses this fundamental material limitation.

Independent endurance insights further contextualize this showdown. RTINGS’ accelerated longevity tests, which simulate extreme static-content exposure for thousands of hours, show that modern OLED panels increasingly exhibit temporary image retention rather than permanent burn-in under realistic usage. While those tests focus largely on larger displays, the underlying trend supports what we see in 2026 flagships: material science, tandem structures, and AI compensation are converging.

Ultimately, the iPhone 17 Pro Max represents software mastery, the Galaxy S26 Ultra showcases material and structural innovation, the Pixel 10 Pro XL integrates AI with service reassurance, and the Xperia 1 VII prioritizes controlled longevity. For enthusiasts, the question is no longer which screen is brightest, but which strategy aligns best with how you actually use your device every day.

What Long-Term RTINGS Burn-In Tests Reveal About Modern OLED Panels

Among long-term burn-in investigations, RTINGS.com’s accelerated longevity test remains one of the most closely watched benchmarks in the industry. Their methodology is intentionally extreme: more than 100 displays are run up to 20 hours a day, showing high-brightness news tickers, static logos, and game HUDs to simulate years of heavy use in a compressed timeframe.

This approach does not reflect typical smartphone behavior, but it provides a stress ceiling. By pushing panels far beyond average consumer patterns, RTINGS reveals how modern OLED materials and compensation algorithms behave when degradation is unavoidable.

Key generational differences highlighted in their public updates include the following trends.

| Model Generation | Hours to Visible Burn-In | Observed Degradation Pattern |

|---|---|---|

| 2018 OLED (e.g., LG C8) | ~8,850 hours | Clear permanent logo ghosting |

| 2024–2025 OLED (e.g., LG G4, Sony A95L) | 14,000+ hours | Mainly temporary image retention |

The shift is striking. Earlier-generation panels developed unmistakable permanent artifacts under static content. In contrast, many recent models show only temporary image retention even after 14,000 hours of torture testing, with compensation cycles restoring much of the uniformity.

Brightness degradation, however, remains measurable. RTINGS reports that after roughly 10,000 hours of accelerated use, peak luminance can drop by 20% to 50%, accompanied by minor color shifts. Yet modern calibration systems appear to mask these changes effectively in real-world viewing.

Industry commentary aligns with these findings. As CNET and other mainstream reviewers have noted, burn-in under normal mixed usage is now considered unlikely for most consumers. The RTINGS data reinforces this view: even under punishing static loads, modern OLED stacks endure significantly longer than their predecessors.

For smartphone enthusiasts, context matters. Phones have smaller panels, higher pixel densities, dynamic UI elements, and shorter replacement cycles—typically three to four years. When extrapolating RTINGS’ television-focused stress results to mobile devices, the risk window narrows further.

Ultimately, the long-term tests reveal not perfection, but progress. Material refinements, tandem structures, and smarter compensation algorithms have meaningfully extended usable life. OLED still ages—but it now does so slowly enough that, for most power users, the display will outlast the device’s practical lifespan.

Practical Burn-In Prevention: Settings and Usage Habits That Actually Work

Even with the latest tandem panels and AI-driven compensation algorithms, your daily settings still matter. Burn-in is fundamentally cumulative pixel wear, and that means small, repeated habits shape long-term panel health. The good news is that a few evidence-based adjustments can dramatically reduce uneven aging without sacrificing visual quality.

According to RTINGS’ large-scale longevity tests, panels exposed to static, high-brightness content for 20 hours a day show measurable luminance drop after thousands of hours. While this is an extreme scenario, it clearly demonstrates one principle: brightness and static elements are the two biggest controllable risk factors.

| Setting / Habit | Why It Works | Impact on Wear |

|---|---|---|

| Adaptive Brightness | Reduces sustained peak current | Lowers thermal stress |

| Dark Mode | Black pixels are off in OLED | Near-zero subpixel aging |

| Short Screen Timeout | Limits static display duration | Reduces uneven exposure |

| Gesture Navigation | Removes fixed nav bar icons | Prevents bottom-edge bias |

Adaptive Brightness should remain enabled at all times. Modern LTPO panels can scale refresh rate and luminance dynamically, but manually locking brightness near maximum forces continuous high current through organic emitters—especially blue subpixels, which research published by the American Chemical Society identifies as the most degradation-prone due to higher photon energy requirements.

Dark Mode is more than an aesthetic preference. On OLED, black pixels are electrically inactive. This means UI backgrounds, keyboards, and messaging apps in dark themes physically reduce organic material usage. Over thousands of hours, that difference becomes meaningful, particularly for users who spend hours daily in productivity or social apps.

Always-On Display should be optimized rather than disabled outright. Both Android 17 and iOS 19 use subpixel shifting and adaptive dimming, but you can go further by disabling AOD in low-utility scenarios such as overnight charging. Apple’s environment-aware AOD already turns off in pockets or when face-down, and ensuring those features remain active prevents unnecessary emission cycles.

Heat management is another overlooked factor. OLED degradation accelerates with temperature because chemical breakdown rates increase under thermal stress. Avoid gaming at maximum brightness while charging, and never leave the device under direct sunlight in a car. Even brief exposure to extreme heat compounds long-term material fatigue.

Wallpaper strategy also matters. High-contrast static logos or bright white backgrounds create localized wear patterns. Rotating darker wallpapers or using subtle gradients distributes pixel usage more evenly. This is particularly relevant for users who rarely change home screen layouts.

Finally, diversify your content. As CNET notes, real-world smartphone burn-in is uncommon partly because users naturally switch apps frequently. If you spend extended sessions in one interface—navigation apps, stock dashboards, or mobile games with fixed HUDs—taking periodic breaks or switching orientation can redistribute load across subpixels.

When these practical habits are combined with modern AI calibration and material advances, the likelihood of visible burn-in within a typical 3–4 year upgrade cycle becomes extremely low. You are not fighting the technology—you are simply allowing its protection systems to work under optimal conditions.

Warranty and Protection Programs: AppleCare+, Samsung Care+, and Pixel Care+

Even though modern OLED panels are far more durable than they were a few years ago, long-term ownership still depends heavily on warranty coverage. For users who push brightness to 3,000 nits outdoors or rely on Always-On Display every day, protection programs are no longer optional—they are part of the buying decision.

AppleCare+, Samsung Care+, and Pixel Care+ approach protection from slightly different angles. The differences are not only about accidental damage, but also about how confidently each brand stands behind display longevity and battery health.

Core Coverage Comparison

| Program | Display Coverage | Battery Policy | Service Model |

|---|---|---|---|

| AppleCare+ | Accidental damage (service fee) | Free replacement below 80% capacity | Express replacement available |

| Samsung Care+ | Screen repair, accidental damage | Plan-dependent coverage | Same-day repair in select cities |

| Pixel Care+ | Screen issues including burn-in | Free battery repairs in program | Mail-in and walk-in options (region-based) |

AppleCare+ continues to be the most seamless in terms of logistics. In Japan, screen repairs are available at a fixed service fee, and Express Replacement can ship a replacement device before you send yours back. Apple officially guarantees battery replacement if maximum capacity drops below 80%, a threshold that reflects industry-standard lithium-ion degradation benchmarks.

While Apple does not market burn-in as a headline issue, its pixel-level calibration system and historical OLED mitigation algorithms reduce the likelihood of visible retention within typical ownership cycles, as discussed by industry analysts and long-term panel testing groups.

Samsung Care+ emphasizes flexibility and speed. In major cities like Tokyo and Osaka, display replacement can be completed in about an hour with a reservation. Theft and loss coverage options have become more common in 2026 plans, lowering psychological risk for high-priced flagship buyers. Samsung Japan’s official warranty information confirms structured support tiers for SIM-free and carrier models.

Given Samsung’s investment in M14 materials and CoE efficiency improvements, pairing hardware durability with rapid repair infrastructure creates a strong value proposition for heavy users.

Pixel Care+, launched alongside newer Pixel generations, takes a more explicit stance on screen reliability. According to PCMag’s coverage of the program launch, it includes battery and screen repairs under its protection structure. Notably, coverage extends to display malfunctions, which can include burn-in under qualifying conditions.

This integration of Android 17’s display health tracking with a formal protection program reflects Google’s service-driven strategy: hardware, software diagnostics, and warranty support working as a single ecosystem.

As RTINGS’ long-term accelerated testing has shown, severe burn-in under normal smartphone usage is increasingly rare. However, brightness loss and gradual uniformity shifts can still occur over thousands of hours. A protection plan therefore acts as financial risk management rather than panic insurance.

For enthusiasts investing in ultra-bright tandem or advanced OLED devices, aligning your usage pattern with the right protection ecosystem is a strategic decision that extends far beyond accidental drops.

Beyond OLED: QDEL, MicroLED, and the Race Toward Burn-In-Free Displays

As OLED mitigation technologies mature, the industry is already looking beyond organic materials altogether. The next battleground is clear: self-emissive displays that deliver OLED-class contrast without the structural risk of burn-in.

Two leading candidates—QDEL and MicroLED—approach this goal from fundamentally different material philosophies. Both replace degradable organic emitters with inorganic light sources, aiming to eliminate the chemical instability that underpins permanent image retention.

| Technology | Light Source | Burn-In Risk (Theoretical) | Key Challenge |

|---|---|---|---|

| OLED | Organic emitters | Material degradation over time | Blue stability |

| QDEL | Electroluminescent quantum dots | Significantly reduced | Mass production readiness |

| MicroLED | Inorganic micro LEDs | Extremely low | High-resolution manufacturing |

QDEL, or Quantum Dot Electroluminescence, allows quantum dots themselves to emit light when electrically stimulated. Unlike today’s QD-OLED, which still relies on a blue OLED backlight, QDEL removes the organic layer entirely. Because quantum dots are inorganic nanocrystals, they are far more resistant to the photochemical breakdown described in research published by ACS regarding OLED degradation mechanisms.

The implication is profound: a self-emissive display without organic decay pathways. Industry analyses cited in market outlook reports suggest that late-2026 could see early premium monitor or smartphone sampling, positioning QDEL as a 2030s mainstream contender if yield challenges are resolved.

MicroLED takes a different route. Instead of nanocrystals, it uses microscopic inorganic LEDs—often measured in micrometers—as individual pixels. According to OLED-Info and related lifetime studies, inorganic LED materials can theoretically exceed 100,000 hours of operational life with minimal luminance decay. That durability dramatically reduces the uneven wear that causes burn-in artifacts.

However, MicroLED’s promise comes with brutal engineering hurdles. Transferring millions of microscopic LEDs onto a smartphone-sized backplane with perfect alignment remains complex and costly. At CES 2026, prototypes demonstrated extreme brightness levels and refined RGB stripe layouts, yet scaling to mass-market smartphone densities remains an open industrial challenge.

In short, the race is no longer about managing burn-in—it is about engineering it out of existence at the material level.

For gadget enthusiasts, this transition signals a structural shift. OLED has become highly resilient thanks to tandem stacks and AI compensation, but QDEL and MicroLED aim to redefine durability benchmarks entirely. If successful, the next decade of smartphones may deliver uncompromised peak brightness, wider color volumes, and effectively burn-in-free operation—without relying on algorithmic corrections to mask aging pixels.

The competition is not merely incremental. It is a materials science arms race that could determine the post-OLED era of premium displays.

参考文献

- CNET:OLED Burn-In: What You Need to Know for TVs, Phones and More

- ACS Publications:The Blue Problem: OLED Stability and Degradation Mechanisms

- LG Display Newsroom:LG Display Becomes World’s First to Verify Commercialization of Blue Phosphorescent OLED Panels

- Omdia:Tandem penetration forecast to reach 36% share of OLED tablet and notebook panel market in 2026

- SamMobile:Samsung Galaxy S26 Ultra’s brilliant display features revealed

- PCMag:Google Launches Pixel Care+ Program With Free Battery, Screen Repairs

- HT Guys Podcast:Podcast #1221: RTINGS Longevity Burn-In Test Updates

- FlatpanelsHD:Is RGB LED a threat to OLED? How LG Display is pushing OLED forward