Have you ever noticed your smartphone getting uncomfortably hot during gaming, video recording, or AI-powered features?

In 2025, this issue is no longer limited to niche devices but affects nearly every high-performance smartphone on the market.

As processors reach 3nm manufacturing, phones now deliver desktop-class power in your pocket, but they also face an unforgiving enemy: heat.

For gadget enthusiasts, overheating is not just about discomfort.

Excess heat directly reduces performance through thermal throttling, shortens battery lifespan, and in extreme cases, raises safety concerns.

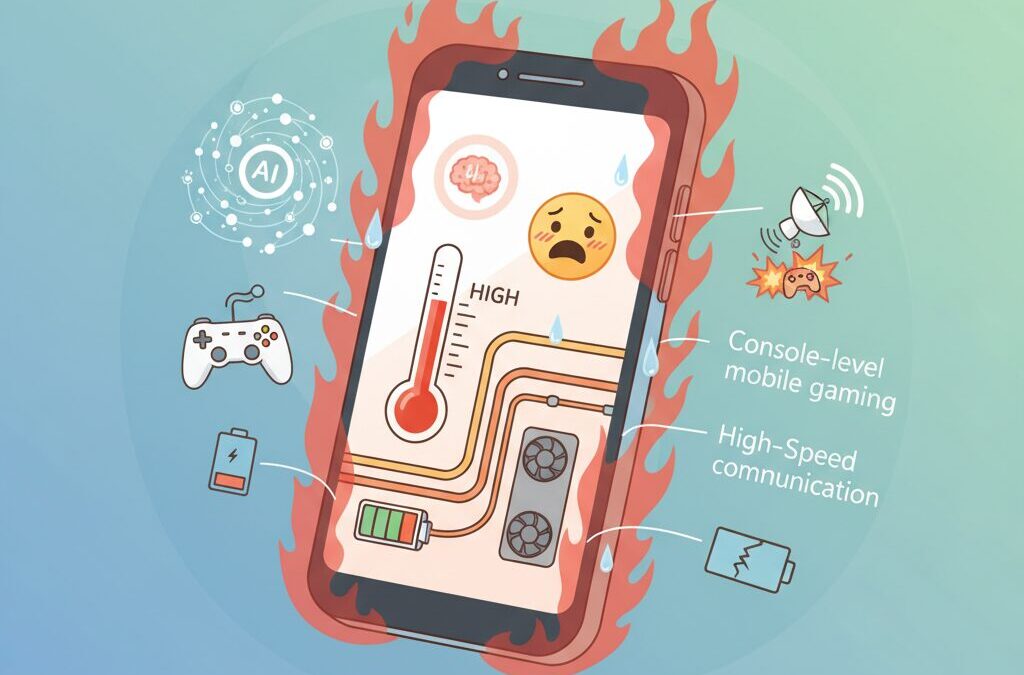

Modern use cases such as on-device generative AI, console-level mobile gaming, and high-speed 5G communication demand sustained performance rather than short bursts of power.

This article helps you understand why smartphones overheat, how manufacturers like Apple, Samsung, Google, and Sony approach thermal management differently, and what real-world benchmarks reveal about cooling performance.

You will also learn how environmental factors and user accessories can make things better or worse.

By the end, you will be able to judge smartphones not just by specs, but by how intelligently they handle heat in everyday use.

- The Thermal Wall Facing Modern Smartphones

- Where Smartphone Heat Really Comes From

- SoC Hotspots, Power Leakage, and Thermal Throttling

- 5G, mmWave, and the Hidden Heat of Connectivity

- Fast Charging and Battery Chemistry Under Stress

- AI Smartphones and the Rise of Sustained Heat Loads

- Gaming Benchmarks That Expose Cooling Differences

- Vapor Chambers vs Graphite and Graphene Cooling

- Apple, Samsung, Google, and Sony: Different Thermal Philosophies

- External Phone Coolers and the Risk of Condensation

- What Heat Means for Safety, Battery Life, and Longevity

- Next-Generation Cooling Technologies Beyond 2025

- 参考文献

The Thermal Wall Facing Modern Smartphones

Modern smartphones are now confronting what many engineers describe as a thermal wall, a point where performance gains collide directly with the immutable laws of physics. As semiconductor processes have reached 3 nm and mobile SoCs rival recent desktop CPUs, the amount of heat generated per square millimeter has increased dramatically.

This shift means that raw benchmark peaks are no longer the defining metric of user experience. **Sustained performance under continuous load has become the real battlefield**, especially for power users who rely on gaming, on-device AI, and real-time media processing.

According to analyses published by XDA Developers and corroborated by McKinsey’s 2025 technology outlook, traditional smartphone workloads were once burst-oriented. Short spikes of activity were followed by idle periods, allowing passive cooling to recover. That assumption no longer holds in 2025.

On-device generative AI, continuous voice transcription, and advanced image processing keep CPUs, GPUs, and NPUs active for minutes or even hours. The result is a steady accumulation of heat that cannot be absorbed by thermal mass alone.

The physical origin of this problem lies in heat density. Every transistor switching event produces Joule heat, and leakage current increases exponentially as temperature rises. Research summarized by Sinda Thermal shows that once a hotspot forms on a mobile SoC, local temperatures can climb far faster than the average chassis temperature suggests.

Unlike desktop CPUs, most smartphone chips lack large heat spreaders, making them vulnerable to highly localized hotspots during AI inference or GPU-heavy gaming scenes.

| Factor | Past Smartphones | 2025 Smartphones |

|---|---|---|

| Process Node | 7–10 nm | 3 nm |

| Workload Pattern | Burst-based | Sustained |

| Thermal Risk | Short-term spikes | Chronic heat buildup |

Communications hardware adds another layer to the challenge. Studies referenced by ViserMark indicate that 5G power amplifiers, particularly at higher frequencies, remain inherently inefficient. Even under controlled lab conditions, early 5G devices showed overheating warnings after roughly 20 minutes of continuous data transmission.

Although network improvements have reduced worst-case scenarios, high-throughput uploads and streaming still contribute significantly to total thermal load.

Battery chemistry further compounds the issue. Fast charging and high discharge rates generate internal heat proportional to the square of current. According to established electrochemical models, including those cited by thermal engineering firms, **every 10°C rise can roughly double the rate of battery degradation**, shortening device lifespan.

All of these factors converge inside a chassis that has barely grown thicker over the last decade.

The thermal wall, therefore, is not a single component failure but a systemic limit. It defines how long modern smartphones can maintain peak intelligence, graphics, and connectivity before physics intervenes. Understanding this constraint is essential for interpreting real-world performance beyond marketing claims.

Where Smartphone Heat Really Comes From

When a smartphone feels hot in your hand, that heat is not coming from a single component but from several sources working simultaneously under strict physical limits. The most dominant origin is the SoC, yet focusing only on the processor oversimplifies the real picture. Modern smartphones are dense systems where computation, communication, and energy storage all convert electrical energy into heat.

The SoC is the primary heat generator because it integrates CPU, GPU, NPU, and ISP on one silicon die. According to analyses cited by XDA Developers and semiconductor thermal studies, every transistor switch produces Joule heat, and at 3 nm-class processes, leakage current becomes increasingly significant at elevated temperatures. This creates localized hot spots only a few millimeters wide, especially during AI inference or GPU-heavy gaming, where heat flux can spike dramatically in short bursts.

| Heat Source | Main Trigger | Thermal Characteristic |

|---|---|---|

| SoC | Gaming, AI, video processing | Localized hot spots, rapid temperature rise |

| 5G Modem & RF | High-speed data transfer | Distributed heat across frame and back |

| Battery | Fast charging, high discharge | Gradual bulk heating |

Communication hardware is the second major contributor. 5G, especially in high-frequency bands, relies on power amplifiers with limited efficiency. Research summarized by ViserMark shows that a large portion of input power is dissipated as heat rather than radio waves. Because modern phones distribute antenna modules around the chassis, this heat spreads to areas directly touched by the user, making the device feel warmer even when the SoC load is moderate.

The battery introduces a different type of thermal behavior. Heat here comes from electrochemical reactions and internal resistance, described by the well-known I²R relationship. Ultra-fast charging amplifies this effect because higher current directly increases heat generation. Industry reports note that even with dual-cell designs and charge pumps, using the phone while charging remains one of the most thermally stressful scenarios.

Display and peripheral circuits add a final layer. High-brightness OLED panels consume more power outdoors, while image sensors and memory operate continuously during video capture. According to PCMag and McKinsey technology analyses, these sustained workloads transform heat from a short-term spike into a steady-state problem, pushing devices toward thermal throttling.

In essence, smartphone heat comes from the convergence of computation, connectivity, and energy flow within an extremely compact space. Understanding these distinct origins explains why devices can overheat even outside gaming scenarios, and why thermal design has become as critical as raw performance.

SoC Hotspots, Power Leakage, and Thermal Throttling

In modern smartphones, heat is not generated evenly across the SoC, and this imbalance is the starting point of many performance problems. As detailed by semiconductor thermal analyses from organizations such as XDA Developers, the most critical issue is the formation of localized hotspots, where a few square millimeters of silicon dissipate a disproportionate amount of power. **These hotspots, rather than the average chip temperature, are what ultimately trigger thermal throttling.**

At the transistor level, power consumption is split into dynamic power and static power, also known as power leakage. Dynamic power scales with switching activity and voltage, while leakage current flows even when transistors are idle. Process nodes have now reached 3 nm, and while this reduces dynamic power per operation, it makes leakage harder to suppress. According to McKinsey’s technology outlook, leakage increases exponentially with temperature, meaning that once a hotspot forms, it actively accelerates further heating. **This positive feedback loop is one reason sustained AI and gaming workloads are so difficult to cool.**

| Thermal factor | Primary cause | Impact on performance |

|---|---|---|

| Dynamic power | High-frequency switching of CPU and GPU cores | Short-term temperature spikes under burst loads |

| Power leakage | Subthreshold and gate leakage at advanced nodes | Sustained heat rise during prolonged workloads |

| Hotspots | Uneven utilization of high-performance cores or GPU units | Early thermal throttling despite moderate average temperature |

Unlike desktop CPUs, smartphone SoCs typically lack a metal heat spreader, leaving heat diffusion to thin graphite layers or vapor chambers. When a GPU shader cluster or a high-performance CPU core is fully loaded, heat flux concentrates faster than it can be spread laterally. Sinda Thermal’s materials research describes this as a heat density problem rather than a total power problem, emphasizing that **even a few watts can overwhelm a tiny silicon area if heat spreading is delayed by milliseconds.**

Thermal throttling is the system’s last line of defense. Once on-die sensors detect temperatures approaching reliability limits, clock frequencies and voltages are reduced automatically. XDA Developers has shown that this often happens well before the device feels uncomfortably hot to the touch, which explains why users see sudden frame rate drops or slower AI inference without obvious external warning. **From the user’s perspective, throttling feels like instability, but from the silicon’s perspective, it is survival.**

The key takeaway is that SoC performance in 2025 is constrained less by peak benchmark scores and more by how effectively hotspots and leakage are managed over time. As workloads shift toward sustained AI inference and console-class graphics, the ability to control localized heat determines whether a flagship chip can maintain its advertised performance or quietly scale itself back minutes after the load begins.

5G, mmWave, and the Hidden Heat of Connectivity

5G connectivity has quietly become one of the most persistent sources of heat inside modern smartphones, especially as networks shift from sub‑6 GHz bands to mmWave. While processors attract most attention, **the cellular modem and its surrounding RF components often sustain heat for far longer periods**, making them a hidden bottleneck for performance and comfort.

At the center of this issue is the power amplifier. According to analysis cited by ViserMark, early 5G devices were prone to overheating even in controlled 23°C environments after roughly 20 minutes of continuous data transfer. The reason is structural: **high‑frequency signals are inherently inefficient to amplify**, so a large portion of the electrical energy is lost as heat rather than radiated as usable signal.

| Connectivity Mode | Typical PA Efficiency | Thermal Characteristic |

|---|---|---|

| 4G LTE | High | Short, burst‑like heating |

| 5G sub‑6 | Medium | Moderate, sustained heating |

| 5G mmWave | Low | Intense, localized heating |

mmWave introduces another complication: antenna placement. Because these signals are easily blocked by hands or clothing, manufacturers deploy multiple antenna‑in‑package modules around the frame and back panel. **Heat is no longer concentrated near the SoC but distributed across areas the user directly touches**, which explains why phones can feel hot even when CPU load appears modest.

Recent reports from McKinsey and XDA Developers note that improved base‑station density has reduced worst‑case scenarios, yet large uploads, hotspot use, and AI‑assisted cloud features still trigger sustained modem activity. In practice, this means that **connectivity, not computation, often dictates thermal throttling during real‑world use**.

As 5G evolves toward always‑connected AI services, the modem’s thermal footprint is becoming a design priority rather than a side concern. Understanding this invisible heat source helps explain why even flagship phones can warm up unexpectedly, long before the processor reaches its limits.

Fast Charging and Battery Chemistry Under Stress

Fast charging has become a defining feature of modern smartphones, but it places significant stress on battery chemistry that is often invisible to users. When charging power climbs to 120W or even 200W, the lithium-ion battery is forced to accept extremely high current, and this directly translates into heat generation inside the cell due to internal resistance. According to established electrochemical models, heat generation follows the I squared R relationship, meaning that even small increases in current can cause disproportionate thermal stress.

From a materials science perspective, high-temperature charging accelerates unwanted side reactions inside the battery. Researchers cited by Sinda Thermal and similar industry sources note that elevated temperatures promote electrolyte decomposition and thickening of the solid electrolyte interphase layer on the anode. This layer is essential for safety, but when it grows too quickly, **capacity fades faster and internal resistance increases**, creating a feedback loop of even more heat during future charging cycles.

| Charging Condition | Typical Cell Temperature Trend | Long-Term Impact |

|---|---|---|

| Standard charging (20–30W) | Gradual rise, often below 40°C | Slower degradation |

| Ultra-fast charging (120W+) | Rapid spikes toward 45–50°C | Accelerated aging risk |

To mitigate these effects, manufacturers increasingly rely on dual-cell architectures and advanced charge pumps that split the current between cells. This approach reduces per-cell stress, but it does not eliminate thermal risk entirely, especially if the device is used during charging. Industry safety guidelines and carrier advisories consistently warn that gaming or AI workloads while fast charging represent the most severe thermal scenario for battery health.

Battery aging also follows well-known chemical laws. Based on the Arrhenius equation, a temperature increase of just 10°C can roughly double reaction rates, which in practical terms means **battery lifespan can be cut in half under sustained heat**. This is why thermal management during fast charging is no longer a secondary concern, but a core design challenge that directly affects durability, safety, and long-term user satisfaction.

AI Smartphones and the Rise of Sustained Heat Loads

AI smartphones are redefining what it means for a handset to be “under load.” Until recently, most mobile workloads were short and bursty, such as opening an app, scrolling a feed, or snapping a photo. In contrast, **on-device AI introduces sustained heat loads that last minutes or even hours**, fundamentally changing thermal design priorities.

According to analyses by XDA Developers and McKinsey, edge AI tasks such as real-time speech transcription, live translation, image segmentation, and background summarization keep NPUs and memory controllers active continuously. This creates a steady-state thermal condition rather than a brief spike, making traditional peak-performance metrics less relevant to real-world usability.

Unlike gaming workloads that fluctuate with scene complexity, AI inference pipelines often run at a fixed cadence. For example, continuous voice processing keeps neural accelerators engaged at predictable but relentless power levels. Semiconductor researchers note that leakage current in advanced 3nm nodes rises exponentially with temperature, meaning sustained heat directly amplifies power loss and accelerates thermal runaway risks.

This shift can be illustrated by comparing classic and AI-centric workloads.

| Workload Type | Typical Duration | Thermal Profile | Main Bottleneck |

|---|---|---|---|

| Web / SNS | Seconds | Burst heat | Peak power |

| Mobile gaming | 10–30 minutes | Rising then throttled | GPU cooling |

| On-device AI | Minutes to hours | Steady-state heat | Heat dissipation efficiency |

Industry data cited by Sinda Thermal shows that AI-enabled smartphones have sharply increased demand for advanced thermal materials, precisely because **lower thermal resistance matters more than sheer heat capacity** under sustained loads. If heat cannot be expelled continuously, the system resorts to frequency caps that slow inference speed, degrading features that are marketed as “instant” or “real time.”

Real-world stress tests support this view. In extended benchmarks such as 3DMark Wild Life Extreme, devices with larger vapor chambers or improved heat-spreading structures maintain higher stability scores over 20 minutes. Reviewers consistently observe that phones optimized for sustained dissipation deliver smoother AI-enhanced camera previews and faster on-device text processing long after peak clocks have dropped.

Academic work on thermodynamics of mobile SoCs further reinforces the point. Researchers emphasize that sustained workloads expose local hot spots on NPUs and memory interfaces, areas that were previously underutilized. **AI does not just add heat; it redistributes heat to components that were not the primary concern in earlier smartphone generations.**

For users fascinated by AI features, this has practical implications. A phone that feels merely warm on the surface may already be operating at its thermal equilibrium limit internally. As AI capabilities expand in 2025 models, sustained heat loads are becoming the silent determinant of responsiveness, battery longevity, and long-term reliability.

Gaming Benchmarks That Expose Cooling Differences

Gaming benchmarks are uniquely effective at revealing cooling differences because they sustain simultaneous CPU, GPU, and memory load in ways that synthetic tests rarely do. Titles such as Genshin Impact or Zenless Zone Zero push modern SoCs into long-duration thermal equilibrium, where cooling design, not peak silicon performance, determines the outcome. According to stress-test methodologies widely referenced by UL Solutions through 3DMark, sustained frame rate stability is a direct proxy for how efficiently heat is transported away from localized hotspots.

What matters here is not the first five minutes, but the twentieth. In controlled testing environments at around 23°C, devices with larger vapor chambers or more aggressive heat spreading consistently maintain higher average FPS over time. This behavior aligns with observations published by XDA Developers, which emphasize that thermal throttling curves, rather than raw benchmark scores, correlate more strongly with perceived gaming smoothness.

| Device Category | 20-min FPS Stability | Cooling Approach |

|---|---|---|

| Gaming-focused phones | 90%+ | Large VC, active or hybrid cooling |

| Mainstream flagships | 55–70% | Mid-size VC or graphite layers |

| Thin-and-light designs | Below 60% | Graphite-centric heat spreading |

These differences become visible as gradual FPS decay rather than sudden drops. Phones with insufficient cooling often oscillate between performance states, creating micro-stutter that benchmarks capture as instability. Notebookcheck has noted that even when average FPS looks acceptable, higher thermal variance increases frame-time spikes, which players perceive as lag.

In other words, gaming benchmarks expose the honesty of a phone’s thermal design. They show whether a device can dissipate heat continuously instead of briefly tolerating it. For users who play graphically intensive games daily, these sustained metrics are far more predictive of real-world satisfaction than any headline performance number.

Vapor Chambers vs Graphite and Graphene Cooling

When discussing modern smartphone cooling, the comparison between vapor chambers and graphite or graphene solutions is no longer theoretical but practical and measurable. Both approaches aim to spread heat away from concentrated hotspots such as the SoC, yet they rely on fundamentally different physical principles that shape real-world performance.

Vapor chambers excel at rapid, high-density heat transport. By exploiting liquid-to-vapor phase change, they can move thermal energy several centimeters almost instantly, which is especially effective under sustained gaming or on-device AI workloads. According to Sinda Thermal’s engineering data, vapor chambers can achieve an effective in-plane thermal conductivity several times higher than solid copper, making them highly resistant to sudden thermal spikes.

| Aspect | Vapor Chamber | Graphite / Graphene |

|---|---|---|

| Heat transfer mechanism | Phase change (liquid–vapor) | Solid-state conduction |

| Strength | Hotspot suppression | Lightweight heat spreading |

| Typical use case | Sustained heavy loads | Thin, weight-sensitive designs |

Graphite and graphene, by contrast, focus on distributing heat laterally across the chassis. Their in-plane thermal conductivity can reach 1,500–1,800 W/mK, far exceeding copper, while remaining extremely light. Apple’s long-standing preference for multilayer graphite reflects a design philosophy prioritizing weight balance and internal volume efficiency. With the introduction of graphene sheets and solid-state diffusion bonding in recent iPhones, Apple claims around a 20 percent improvement in heat dissipation efficiency, as noted by PCMag and ZDNET.

The trade-off becomes visible in stress tests. Devices with large vapor chambers tend to maintain higher performance stability over 20-minute benchmarks, while graphite- or graphene-focused designs often feel cooler to the touch initially but throttle earlier under prolonged load. Industry analyses from outlets like XDA Developers highlight that neither solution is universally superior; instead, each represents a deliberate optimization between thermal endurance, device weight, and internal layout.

Apple, Samsung, Google, and Sony: Different Thermal Philosophies

When it comes to thermal management, Apple, Samsung, Google, and Sony are solving the same physics problem with fundamentally different philosophies, and those choices directly shape real-world performance.

Rather than converging on a single “best” solution, each company optimizes cooling around its broader product values: weight, sustained performance, AI workloads, or ecosystem integration.

| Brand | Primary Cooling Strategy | Design Priority |

|---|---|---|

| Apple | Graphite / graphene heat spreading | Weight, thinness, balanced throttling |

| Samsung | Large vapor chamber | Peak and sustained performance |

| Vapor chamber + AI scheduling | Stable AI inference | |

| Sony | Passive body + optional active cooling | Form factor and modularity |

Apple’s approach is rooted in heat diffusion rather than heat transport. iPhones rely on multi-layer graphite and, more recently, graphene sheets to spread heat laterally across the chassis. According to PCMag and ZDNet coverage of the iPhone 16 Pro, Apple enhanced internal aluminum–titanium bonding to improve solid-state heat flow by roughly 20 percent. This design avoids the mass and volume penalty of copper vapor chambers, but benchmark stress tests reported by Notebookcheck and independent reviewers consistently show earlier thermal throttling compared to Android flagships. Apple appears to accept controlled performance tapering as a trade-off for comfort, weight balance, and battery longevity.

Samsung represents the opposite philosophy. The Galaxy S24 Ultra’s vapor chamber is nearly twice the size of its predecessor, a fact confirmed by GSMArena teardowns. Samsung treats thermal headroom as a performance enabler, allowing the Snapdragon 8 Gen 3 to sustain higher clocks for longer under gaming and 3DMark stress tests. The cost is internal space and added mass, but Samsung prioritizes measurable endurance under load, aligning with its “Ultra” branding and power-user audience.

Google’s recent shift is particularly revealing. After multiple Tensor generations criticized for overheating, Pixel 9 Pro models finally adopted a vapor chamber, as detailed by Android Headlines teardown analyses. However, Google complements hardware cooling with software-first thermal governance. XDA Developers notes that Pixel devices aggressively schedule AI tasks across CPU, GPU, and NPU to avoid localized hotspots. The result is not class-leading peak performance, but notably improved stability during sustained AI inference, which is central to Gemini Nano features.

Sony stands apart with a modular mindset. Xperia devices maintain slim, lightweight bodies with limited internal thermal mass, a constraint highlighted in Notebookcheck’s long-term camera tests. Sony’s answer is not to oversize internal cooling, but to extend the thermal system beyond the phone itself. The Xperia Stream external active cooler, documented by HardwareZone and Sony’s own engineering briefings, transforms the phone into a docked, actively cooled device for gaming and streaming. This reflects Sony’s heritage in professional equipment, where accessories complete the system rather than being compromises.

Seen together, these philosophies explain why thermal behavior feels so different across brands. Cooling is not just an engineering detail, but a statement of what each company believes a smartphone should prioritize under pressure.

External Phone Coolers and the Risk of Condensation

External phone coolers have become a popular solution among mobile gamers and power users who want to maintain peak performance under sustained load. Many of these accessories rely on thermoelectric, or Peltier, elements that can actively pull heat away from the phone’s back panel and reduce surface temperatures far more aggressively than passive airflow alone.

This strength, however, is also their most overlooked risk. By cooling the phone surface below the ambient dew point, external coolers can trigger condensation, especially in humid environments such as summer conditions in Japan or Southeast Asia. Condensation is not merely cosmetic moisture; it represents liquid water forming where electronics are never designed to encounter it.

| Factor | Passive Fan Cooler | Peltier-Based Cooler |

|---|---|---|

| Minimum achievable temperature | Near ambient | Below ambient |

| Condensation risk | Very low | High in humid air |

| Cooling response speed | Gradual | Rapid |

| Typical use case | Long gaming sessions | Short, peak-load bursts |

The physics behind this phenomenon is well understood. When a surface temperature drops below the dew point of the surrounding air, water vapor condenses into liquid droplets. Research published through the U.S. National Institutes of Health has shown that thermoelectric cooling systems can create localized condensation even in open-air configurations, depending on orientation and airflow. Smartphones are not hermetically sealed devices, so internal air inevitably contains moisture.

Once condensation forms inside the device, the damage can be subtle but severe. Microscopic droplets on circuit boards accelerate corrosion, increase leakage currents, and in extreme cases cause short circuits. Major carriers, including SoftBank, have publicly warned that water damage indicators triggered by internal condensation are treated the same as liquid immersion, even on phones with IP-rated water resistance.

Real-world user reports and teardown inspections support these warnings. After extended use of Peltier coolers, some users have found visible moisture on the inner surface of phone cases or temporary malfunctioning touch panels. Waterproofing standards are designed to block external water ingress, not to prevent moisture already inside the enclosure from condensing onto cold components.

For enthusiasts determined to use external cooling, risk management becomes essential. Cooler designs with temperature sensors and automatic throttling help prevent the phone surface from dropping too far below ambient conditions. From an engineering safety perspective, airflow-only fan coolers offer a more conservative balance, sacrificing peak cooling capacity to avoid crossing the condensation threshold.

External phone coolers can preserve performance, but they also bypass the manufacturer’s carefully balanced thermal design. Understanding condensation risk is crucial, because in the pursuit of lower temperatures, users may unknowingly expose their devices to one of the most damaging elements in electronics: liquid water formed from the air itself.

What Heat Means for Safety, Battery Life, and Longevity

Heat is not just a comfort issue in modern smartphones. It directly affects user safety, battery degradation, and the long-term reliability of internal components, making thermal behavior one of the most critical yet misunderstood aspects of device quality.

From a safety perspective, lithium-ion batteries are especially sensitive to elevated temperatures. According to data summarized by Japanese consumer safety authorities and reinforced by academic battery research, most smartphone batteries are designed to operate optimally below around 35°C. Once internal temperatures approach 45–50°C, unwanted side reactions accelerate, increasing internal pressure and, in extreme cases, the risk of swelling or thermal runaway.

Battery lifespan is even more directly tied to heat. Electrochemical studies based on the Arrhenius equation show that reaction rates roughly double with every 10°C increase in temperature. Applied to smartphones, this means a device regularly operating at 40°C can lose usable battery capacity nearly twice as fast as one kept near 30°C. Thermal engineers cited by Sinda Thermal note that even a 2°C sustained increase can measurably reduce component reliability over time.

This explains why heavy gaming, on-device AI processing, and fast charging have a compounding effect. Each generates heat individually, but together they create long periods of elevated temperature that age the battery faster than casual use ever did. Users may notice this as earlier battery health warnings, reduced peak charging speed, or sudden drops in percentage under load.

| Temperature Range | Primary Impact | Long-Term Effect |

|---|---|---|

| Below 30°C | Stable operation | Maximum battery longevity |

| 30–40°C | Normal thermal stress | Gradual capacity loss |

| 40–50°C | Accelerated chemical aging | Noticeable lifespan reduction |

| Above 50°C | Safety mechanisms activate | Risk of swelling or shutdown |

Longevity is not limited to the battery alone. Repeated thermal cycling stresses solder joints, adhesives, and connectors on the mainboard. Semiconductor reliability studies referenced by major component suppliers indicate that higher operating temperatures shorten the mean time to failure of SoCs and memory chips. This is one reason manufacturers aggressively throttle performance when temperatures rise, prioritizing hardware survival over short-term speed.

There is also a user-facing safety dimension. Government fire safety statistics in Japan show that the vast majority of smartphone-related fire incidents are linked to lithium-ion batteries under abnormal conditions, such as heat accumulation during charging or use in hot environments. While modern phones include multiple protection circuits, these systems assume normal thermal conditions and cannot fully compensate for chronic overheating.

Ultimately, heat acts as a silent multiplier of risk. It shortens battery life, erodes component reliability, and narrows the margin of safety built into the device. Understanding this relationship helps explain why thermal design, usage habits, and environmental temperature matter just as much as raw performance specs when evaluating a smartphone’s true durability.

Next-Generation Cooling Technologies Beyond 2025

As smartphone performance pushes beyond the limits seen in 2025, cooling technologies are entering a fundamentally new phase. The focus is no longer limited to spreading heat efficiently, but to actively preventing heat buildup before it compromises sustained performance. **Next-generation cooling is shifting from passive materials to intelligent, system-level solutions** that treat heat as a dynamic variable rather than a static problem.

One of the most closely watched breakthroughs is solid-state active cooling. Frore Systems’ AirJet technology, already demonstrated in ultra-thin laptops and industrial modules, uses ultrasonic MEMS vibration to generate airflow without blades or motors. According to disclosures from Frore Systems and analyses cited by PCMag, AirJet-class devices can move meaningful volumes of air within millimeter-thin enclosures while consuming only a few watts. For smartphones, this opens the possibility of true internal active cooling without the thickness, noise, or mechanical wear of traditional fans.

| Technology | Cooling Principle | Key Advantage |

|---|---|---|

| Solid-state active cooling | Ultrasonic airflow (MEMS) | No moving parts, ultra-thin |

| Predictive thermal AI | Workload forecasting | Prevents throttling before it starts |

| Diamond-based substrates | Ultra-high thermal conductivity | Reduces heat at the source |

Equally important is the rise of AI-driven predictive thermal management. McKinsey and XDA Developers both note that on-device AI workloads are sustained rather than bursty, making reactive throttling inefficient. Future systems analyze user behavior, app context, and sensor data to anticipate heat spikes. **Instead of lowering clocks after temperatures rise, the system reshapes workloads in advance**, redistributing tasks across CPU, GPU, and NPU to maintain stable thermals with minimal user-visible impact.

At the materials level, research is accelerating beyond copper, graphite, and even graphene. Diamond-based substrates and diamond-like carbon layers, long studied in power electronics, offer thermal conductivity several times higher than silicon. Industry researchers referenced by Sinda Thermal suggest that hybrid silicon-diamond interfaces could dramatically reduce hotspot intensity, attacking heat generation at its origin rather than merely spreading it.

These technologies signal a clear trajectory: future smartphones will not simply endure heat, they will actively negotiate with it. **Beyond 2025, cooling becomes a co-processor of sorts**, quietly orchestrating airflow, materials, and computation to sustain performance in an era defined by continuous AI, advanced graphics, and rising ambient temperatures.

参考文献

- XDA Developers:The silent killer of your phone’s performance: thermal throttling

- ViserMark:Too Hot to Handle? 5G Phones and the Overheating Challenge in 2025

- McKinsey & Company:Technology Trends Outlook 2025

- GSMArena:Samsung Galaxy S24 Ultra teardown reveals extensive vapor chamber

- Android Headlines:Pixel 9 Pro teardown videos reveal new vapor chamber in detail

- PCMag:On iPhone 16 and 16 Pro, New Cooling Architecture Lets You Run Big Games

- Sinda Thermal Technology:Heatpipe and vapor chamber cooling solution in smartphone