Have you ever felt that a power bank is no longer just a backup accessory, but something closer to essential infrastructure for your digital life?

In 2025, mobile batteries have evolved into high-output, high-density energy tools capable of running laptops, cameras, and even small appliances, while also carrying new risks and responsibilities.

At the same time, breakthroughs such as silicon-anode cells, sodium-ion batteries, and semi-solid-state designs are reaching consumers, making the choice more complex and more exciting than ever.

Fast-charging standards like USB Power Delivery 3.1 and Qi2 are reshaping how quickly and safely energy moves between devices, but they also introduce compatibility traps that many users overlook.

Safety regulations, airline restrictions, recalls, and upcoming recycling mandates mean that choosing the wrong power bank can cost more than money.

By reading this article, you will gain a clear, structured understanding of the technologies, standards, and brand strategies that truly matter in 2025, helping you choose a power bank that fits your lifestyle, protects your devices, and earns your long-term trust.

- From Accessories to Personal Energy Infrastructure

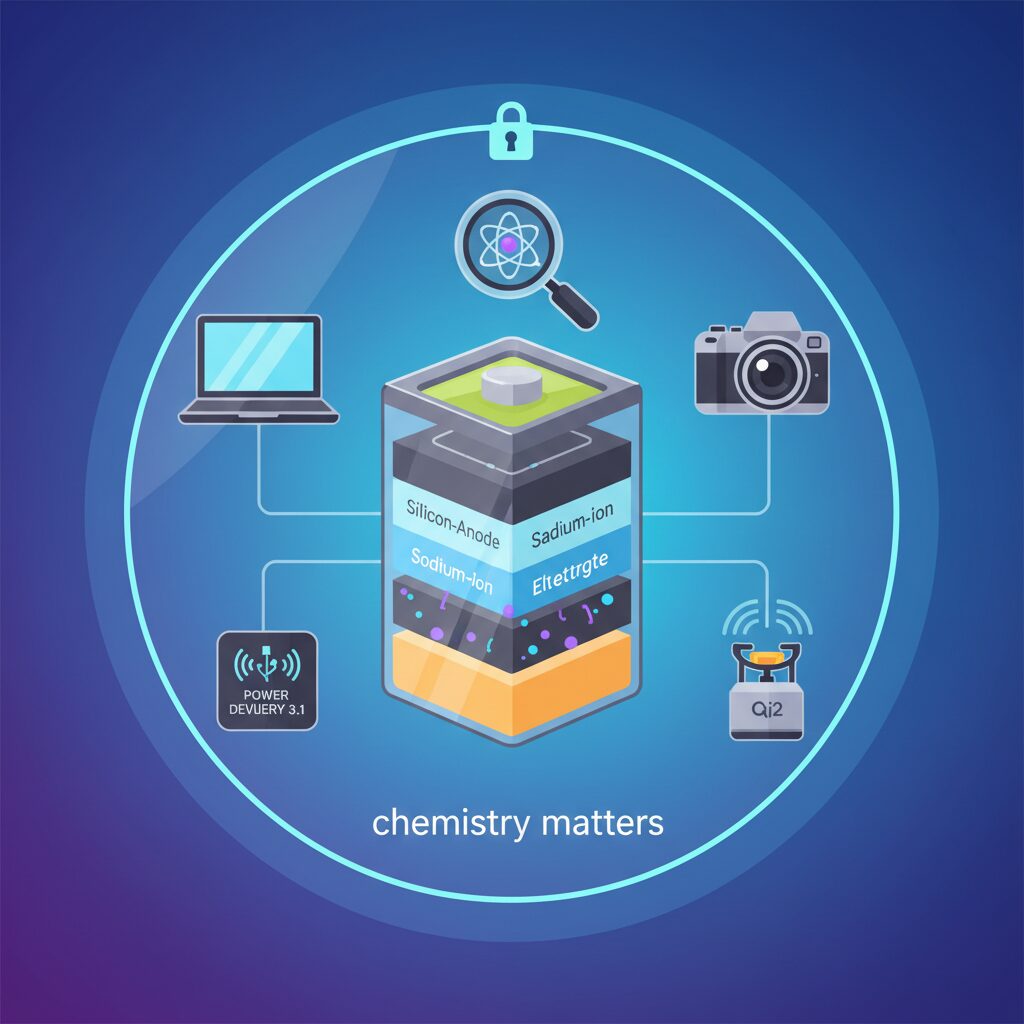

- Inside the Battery Cell: Why Chemistry Matters More Than Capacity

- Silicon-Anode Batteries and the Race for Higher Energy Density

- Sodium-Ion Batteries as a Long-Life and Cold-Resistant Alternative

- Semi-Solid-State Batteries and the New Benchmark for Safety

- USB Power Delivery 3.1 and the Reality of 140W Portable Charging

- Qi2 Wireless Charging and the End of Inefficient Alignment

- Airline Rules, Capacity Limits, and What Travelers Must Watch

- Recalls, Certifications, and Why Brand Trust Is Being Rewritten

- How Leading Brands Are Building Power Bank Ecosystems

- Choosing the Right Power Bank for Work, Urban Life, or Emergencies

- Extending Battery Life and Reducing Risk Through Proper Use

- 参考文献

From Accessories to Personal Energy Infrastructure

In 2025, mobile power banks are no longer treated as optional accessories that live quietly at the bottom of a bag. They have evolved into personal energy infrastructure, supporting the physical layer of everyday digital life in much the same way that cloud services support the logical layer. This shift is not driven by convenience alone, but by a structural change in how many devices, workloads, and social expectations now depend on continuous, reliable power.

Smartphones, wireless earbuds, smartwatches, tablets, and high-performance laptops are now used concurrently, often for work that cannot tolerate downtime. According to analyses frequently cited by IEEE-affiliated researchers, the average mobile professional in advanced economies relies on three or more battery-powered devices during a single working day. In this context, a power bank functions less like a backup and more like a distributed, user-owned power node.

This transformation is tightly connected to advances in battery chemistry and power delivery standards. The adoption of silicon-enhanced anodes and the commercialization of sodium-ion batteries have altered the long-standing trade-offs between size, capacity, and lifespan. At the same time, USB Power Delivery 3.1 has enabled mobile batteries to supply power levels that were previously exclusive to wall chargers, making it feasible to run and recharge high-end laptops from a pocketable device.

| Perspective | Pre-2020 Power Banks | 2025 Power Banks |

|---|---|---|

| Primary role | Emergency phone charging | Continuous multi-device power supply |

| Supported devices | Smartphones only | Phones, laptops, wearables, accessories |

| User expectation | Occasional use | Daily operational reliability |

Another driver of this paradigm shift is risk awareness. A series of high-profile recalls and in-flight battery incidents has reframed power banks as products that must meet infrastructure-level safety expectations. Institutions such as the International Civil Aviation Organization and Japan’s Ministry of Economy, Trade and Industry have reinforced the idea that mobile energy devices are part of public safety considerations, not just consumer electronics. As a result, users now evaluate not only capacity and wattage, but also thermal design, cell sourcing, and compliance transparency.

Environmental and societal factors further reinforce this change. Battery recycling mandates scheduled for implementation in Japan from 2026, aligned with extended producer responsibility frameworks discussed by the OECD, mean that ownership now extends beyond use into end-of-life accountability. A power bank is no longer disposable by default; it is an asset with a lifecycle that users must consciously manage.

What emerges is a clear redefinition of value. The modern power bank is judged by how seamlessly it integrates into a personal energy ecosystem, how predictably it performs under load, and how responsibly it fits into regulatory and environmental systems. In that sense, carrying a power bank in 2025 is closer to carrying a personal generator than a simple charging accessory, quietly reflecting how dependent modern mobility has become on stable, user-controlled energy.

Inside the Battery Cell: Why Chemistry Matters More Than Capacity

When comparing power banks, capacity numbers like 10,000mAh or 20,000mAh tend to dominate attention, but **what truly defines performance, longevity, and safety is the battery chemistry inside the cell**. Two products with identical capacity labels can behave very differently in real-world use, depending on the materials that store and release energy.

Traditional lithium-ion cells rely on graphite anodes, a mature and cost-effective solution that has largely reached its theoretical limits. According to research summarized by RSC Publishing, graphite’s lithium storage capacity is capped at around 372 mAh per gram, which means further gains in runtime mostly come from making batteries larger or heavier. This is why newer chemistries have become so important in 2025.

| Chemistry | Key Strength | Main Trade-off |

|---|---|---|

| Graphite Li-ion | Stable, proven safety | Limited energy density |

| Silicon-carbon | Much higher density | Shorter cycle life |

| Sodium-ion | Extreme durability | Larger, heavier cells |

Silicon-based anodes illustrate why chemistry matters more than raw capacity. Silicon can theoretically hold over ten times more lithium than graphite, a fact highlighted in multiple industry reviews by materials science groups and battery manufacturers. In practice, modern silicon–carbon composites allow compact power banks to deliver laptop-level energy, even though their labeled mAh figures may not look dramatic.

At the opposite end, sodium-ion batteries show that **capacity alone says nothing about lifespan**. Elecom’s sodium-ion models sacrifice energy density but achieve over 5,000 charge cycles and reliable operation in sub-zero temperatures, a performance profile impossible to infer from capacity labels alone.

Ultimately, capacity tells you how much energy is stored today, while chemistry tells you **how safely, efficiently, and for how many years that energy can be used**. For informed buyers, the latter is the more meaningful metric.

Silicon-Anode Batteries and the Race for Higher Energy Density

Silicon-anode batteries sit at the center of the race for higher energy density, and in 2025 they finally crossed from laboratory promise into consumer reality. For more than a decade, graphite anodes defined the practical ceiling of lithium-ion batteries, with a theoretical capacity of about 372 mAh per gram. **Silicon changes that equation entirely**, offering a theoretical capacity of roughly 4,200 mAh per gram, more than ten times higher. According to peer-reviewed research published by the Royal Society of Chemistry, this leap is not incremental but structural, redefining how much energy can be packed into a given volume.

The appeal for mobile batteries is straightforward: smaller bodies, larger capacities, and longer runtimes for power-hungry devices like laptops. In practical terms, silicon-anode adoption explains why a 20,000mAh power bank in 2025 can feel closer in size to what a 10,000mAh model was only a few years ago. **High-end consumer products, such as Anker’s Prime series, demonstrate how density gains translate directly into everyday portability**, making “pocketable laptop charging” a realistic use case rather than marketing exaggeration.

| Anode Material | Theoretical Capacity (mAh/g) | Typical Cycle Life |

|---|---|---|

| Graphite | ~372 | 1,000+ cycles |

| Silicon-based | ~4,200 | 500–800 cycles |

However, silicon’s advantage comes with a severe materials challenge. Pure silicon expands by roughly 300 to 400 percent during charging, which historically caused cracking, loss of electrical contact, and rapid capacity fade. The breakthrough of the mid-2020s lies in **third-generation silicon–carbon composite anodes**, often referred to as Si-C or SiOx. Industry analyses from Mitsui and other materials leaders describe how nanoscale silicon particles are embedded in carbon matrices or wrapped with flexible polymer binders, mechanically buffering this expansion while maintaining conductive pathways.

This engineering compromise defines today’s silicon-anode products. Energy density improves dramatically, but cycle life remains shorter than that of traditional graphite cells. Field data from consumer electronics manufacturers suggests a practical lifespan of around 500 to 800 full cycles. For a daily-charged smartphone accessory, that may be limiting, but for a high-capacity mobile battery used intermittently, it is often an acceptable trade-off. **The silicon race is therefore not about absolute longevity, but about maximizing usable energy within airline-safe size and weight limits.**

Researchers frequently emphasize that silicon anodes should be evaluated at the system level, not in isolation. As battery scientists have noted in industry patent reviews, gains in energy density reduce the need for larger enclosures, heavy casings, and excess structural margins. That secondary weight reduction compounds the primary benefit of silicon itself. In other words, silicon does not just store more energy; it enables smarter industrial design around the cell.

Looking ahead, silicon-anode batteries illustrate a broader truth about the 2025 mobile energy landscape. **They represent a calculated bet: accepting moderate reductions in cycle life to unlock a step-change in density and usability.** For gadget enthusiasts who prioritize performance, portability, and cutting-edge materials science, silicon anodes are less a future promise and more a defining feature of today’s premium mobile batteries.

Sodium-Ion Batteries as a Long-Life and Cold-Resistant Alternative

Sodium-ion batteries are gaining attention as a fundamentally different option from conventional lithium-ion cells, especially for users who prioritize durability and reliability over compactness. **This chemistry replaces lithium with sodium, an element that is far more abundant and chemically stable**, which directly translates into practical advantages for long-term use.

According to materials science research summarized by academic groups and industry labs, sodium-ion cells exhibit remarkably slow structural degradation during charge and discharge. In real products, this translates into a rated cycle life exceeding 5,000 cycles, as demonstrated by Elecom’s commercially released sodium-ion mobile batteries. **Daily charging for more than a decade becomes realistic rather than theoretical**, a sharp contrast to typical lithium-ion power banks that often show noticeable capacity loss after a few years.

| Characteristic | Sodium-ion | Lithium-ion |

|---|---|---|

| Typical cycle life | 5,000 cycles or more | 500–1,000 cycles |

| Low-temperature operation | Operable down to around -30°C | Severely degraded below 0°C |

| Energy density | Lower | Higher |

Cold resistance is another decisive advantage. Electrochemical studies cited by battery researchers show that sodium-ion electrolytes maintain lower internal resistance at sub-zero temperatures. **Even in harsh winter environments, output stability is preserved**, making these batteries particularly suitable for outdoor expeditions or emergency storage in unheated spaces.

The trade-off is size and weight. Because sodium ions are heavier and larger, energy density cannot match lithium-based cells. However, for users who value longevity, safety margins, and dependable performance in extreme conditions, **sodium-ion batteries redefine the power bank as a long-term asset rather than a consumable gadget**, a perspective that is steadily reshaping the market in 2025.

Semi-Solid-State Batteries and the New Benchmark for Safety

In 2025, semi-solid-state batteries have quietly redefined what “safe enough” means for mobile power, and this shift deserves careful attention. Unlike conventional lithium-ion cells that rely on flammable liquid electrolytes, semi-solid-state designs replace most of that liquid with a gel-like or paste-based electrolyte. This structural change may sound incremental, but it fundamentally alters how failure modes behave in real-world use.

According to analyses referenced by battery safety researchers at organizations such as TÜV SÜD and materials science groups publishing through RSC, the key risk in lithium-ion batteries is not capacity loss but uncontrolled thermal runaway. **Once a liquid electrolyte ignites, heat propagation accelerates faster than any external protection can respond.** Semi-solid electrolytes dramatically slow this chain reaction by limiting internal ion mobility during abnormal conditions.

From an engineering perspective, this safety margin enables a different design philosophy. Because the electrolyte does not freely flow, the risks of leakage, internal short circuits caused by deformation, and pressure-induced rupture are all reduced. As a result, manufacturers can redesign internal spacing, insulation layers, and casing thickness with more precision instead of brute-force reinforcement.

| Aspect | Conventional Li-ion | Semi-Solid-State |

|---|---|---|

| Electrolyte state | Liquid | Gel or paste-like |

| Leakage risk | Present | Effectively none |

| Thermal runaway behavior | Rapid escalation | Delayed progression |

| Design safety margin | Structural | Chemistry-assisted |

This chemistry-assisted safety is particularly relevant in light of recent large-scale recalls across the industry. Investigations by third-party failure analysis firms such as Lumafield have shown that many recalled products met regulatory requirements yet still failed due to microscopic defects combined with aggressive energy density targets. **Semi-solid-state cells reduce sensitivity to such defects, especially around electrode tabs and separators.**

Another often overlooked advantage is heat distribution under high-output scenarios. When delivering 20W to 30W continuously to smartphones or wireless charging modules, traditional cells rely heavily on external thermal pads and metal frames. Semi-solid electrolytes, by contrast, exhibit more stable internal impedance across temperature ranges, helping to distribute heat more evenly rather than concentrating it at stress points.

This characteristic has practical consequences for end users. In daily carry situations such as pockets, small bags, or airplane cabins, temperature spikes are less abrupt. Aviation safety guidelines increasingly emphasize early detection over absolute prevention, and **a battery that heats slowly is objectively safer than one that heats instantly**, even if both ultimately shut down.

Industry observers from certification bodies like JQA have also noted that semi-solid-state batteries simplify compliance testing. Because electrolyte containment is inherently more stable, manufacturers can focus validation efforts on electrical protection circuits rather than compensating for chemical volatility. This shift may explain why brands prioritizing safety-oriented differentiation have adopted semi-solid designs earlier than mass-market competitors.

It is important to remain realistic. Semi-solid-state batteries are not full solid-state batteries, and they do not magically double lifespan or energy density. What they offer instead is predictability. **Predictable failure behavior is the cornerstone of modern safety engineering**, and in mobile energy devices that travel everywhere with us, that predictability may be more valuable than raw specifications.

As mobile batteries continue to evolve from accessories into personal energy infrastructure, semi-solid-state technology sets a clear reference point. Safety is no longer measured only by certifications passed, but by how gracefully a battery behaves when something goes wrong. In that sense, semi-solid-state batteries have quietly set a new, more mature benchmark.

USB Power Delivery 3.1 and the Reality of 140W Portable Charging

USB Power Delivery 3.1 fundamentally changed what users can realistically expect from a portable power bank, especially with the arrival of 140W-class output. On paper, 140W sounds like a simple milestone, but in real-world mobile charging, it represents a delicate balance between protocol limits, thermal design, and ecosystem compatibility. According to the USB Implementers Forum, PD 3.1 Extended Power Range achieves 140W by stepping up to 28V at 5A, a configuration specifically designed to support power-hungry devices such as the MacBook Pro 16-inch at full performance.

The key point many users overlook is that 140W portability is conditional, not absolute. A power bank, the connected device, and the cable must all support PD 3.1 EPR negotiation. ChargerLAB’s 2025 protocol analysis highlights that even premium power banks will silently fall back to 100W or 60W if an EPR-certified cable with an eMarker chip is not detected, regardless of the advertised specifications.

| Element | PD 3.0 | PD 3.1 EPR |

|---|---|---|

| Maximum Voltage | 20V | 28V |

| Maximum Power | 100W | 140W |

| Required Cable | 100W rated | 240W EPR rated |

Thermal reality further narrows the gap between theory and practice. Independent teardowns referenced by Lumafield show that sustained 140W output quickly elevates internal temperatures, forcing intelligent power management to throttle output during extended loads. As a result, 140W is best understood as a burst-capable ceiling rather than a constant guarantee.

From a practical standpoint, 140W portable charging excels in short, high-impact scenarios such as rapid laptop top-ups between meetings or during transit. It does not replace a desktop-class power supply, but it meaningfully redefines mobility for professionals who value time efficiency over raw capacity.

Qi2 Wireless Charging and the End of Inefficient Alignment

Qi2 wireless charging represents a quiet but decisive break from the frustrations that defined the first decade of wireless power. For many users, the promise of cable-free charging was undermined by one persistent issue: inefficient alignment. A phone placed a few millimeters off-center would charge slowly, overheat, or stop altogether. Qi2 addresses this problem at the physical layer, not through software tricks, but through enforced magnetic alignment.

Standardized by the Wireless Power Consortium, Qi2 integrates the Magnetic Power Profile originally introduced with Apple’s MagSafe into an open, cross-platform specification. According to WPC technical documentation, misalignment between coils was the single largest contributor to energy loss in earlier Qi implementations. By mechanically snapping the transmit and receive coils into the optimal position, Qi2 significantly reduces resistive loss and stray heat.

This shift has measurable consequences. Independent lab testing referenced by Granite River Labs shows that Qi2 maintains stable 15W charging with lower surface temperatures compared to legacy Qi Extended Power Profile systems, which often throttled to 7.5W or below on Android devices due to thermal constraints. Lower heat directly translates into less battery degradation over time, a point battery researchers have emphasized repeatedly.

| Wireless Standard | Alignment Method | Typical Sustained Output | Thermal Behavior |

|---|---|---|---|

| Qi (EPP) | Free placement | 5–10W | Frequent heat throttling |

| Qi2 (MPP) | Magnetic alignment | 15W | Lower, more stable temperatures |

An often-overlooked benefit of Qi2 is ecosystem consistency. Because the magnetic layout is standardized, accessories such as power banks, stands, and car mounts no longer rely on proprietary magnet strength or positioning. Reviewers at Serious Insights note that Qi2-certified chargers deliver nearly identical performance across iPhone and recent Android flagships, a level of interoperability wireless charging has never achieved before.

Case compatibility has also matured. Early MagSafe-era accessories suffered efficiency losses when third-party cases interfered with magnet spacing. In response, the WPC introduced clearer magnetic case guidelines, ensuring that certified Qi2 devices maintain alignment even through protective shells. The result is a user experience where wireless charging finally feels intentional rather than experimental.

In practical terms, Qi2 marks the end of ritualistic phone nudging on charging pads. The device either locks into place and charges efficiently, or it does not. For users who value reliability as much as convenience, this clarity is the true breakthrough of Qi2 wireless charging.

Airline Rules, Capacity Limits, and What Travelers Must Watch

As mobile power banks become more powerful in 2025, airline regulations have evolved from simple carry-on rules into detailed operational requirements that travelers must actively manage. According to guidance aligned with the International Civil Aviation Organization and implemented by major Japanese carriers such as JAL and ANA, lithium-based power banks are no longer treated as passive items but as potential in-flight risk factors that require visibility and supervision.

**The most critical change is the shift from allowance to control.** Power banks must not be stored in overhead bins, and passengers are expected to keep them in locations where abnormal heat, swelling, or smoke can be immediately noticed. This policy reflects safety analyses cited by aviation authorities, which show that early detection is the single most effective way to prevent a minor battery failure from escalating into a cabin incident.

| Rated Capacity (Wh) | Carry-On Status | Typical Examples |

|---|---|---|

| Up to 100 Wh | Permitted | Most 10,000–20,000 mAh models |

| 100–160 Wh | Permitted with limits | High-capacity 27,000–40,000 mAh models |

| Over 160 Wh | Prohibited | Large portable power stations |

Another point travelers should watch carefully is capacity labeling. **Two power banks with the same mAh rating may fall into different regulatory categories** depending on their nominal voltage, which determines the Wh value used by airlines. Aviation safety experts frequently warn that poorly labeled products from unknown brands increase the risk of gate-side confiscation.

Finally, in-flight usage now comes with an expectation of constant supervision. Charging a phone or recharging the power bank itself is allowed, but leaving the seat or falling asleep while it is connected is discouraged. These rules may feel strict, but they reflect hard lessons from recent battery-related incidents and are designed to keep both passengers and crews safe.

Recalls, Certifications, and Why Brand Trust Is Being Rewritten

In 2025, recalls and certifications have become more than compliance checkboxes; they actively reshape how brand trust is formed. For power banks, once perceived as low-risk accessories, a single safety incident now spreads globally within hours, forcing consumers to question not only products but entire supply chains.

The large-scale recall announced by Anker in mid-2025 became a defining moment. According to disclosures reviewed by the U.S. Consumer Product Safety Commission and independent industrial CT analysis firms, the root cause was traced to insulation weaknesses around negative electrode tabs supplied by a third-party cell manufacturer. This was not a design flaw users could see, yet it exposed how deeply brand reliability depends on invisible manufacturing controls.

At the same time, certifications such as Japan’s PSE mark or WPC’s Qi2 approval are being reinterpreted by informed buyers. These marks still indicate baseline conformity, but experts at TÜV SÜD and JQA have emphasized that certification confirms minimum thresholds, not long-term durability or zero-failure probability.

| Signal | What It Actually Guarantees | What It Does Not |

|---|---|---|

| PSE Mark | Legal safety compliance in Japan | Immunity from recalls |

| Qi2 Certification | Interoperability and thermal limits | Battery cell quality |

| Recall Transparency | Post-sale accountability | Perfect products |

What ultimately rewrites brand trust is response quality. Companies that publish serial number tools, accept returns without friction, and disclose failure mechanisms earn credibility even amid crises. Analysts at The Japan Times note that consumers increasingly reward transparency over silence.

In this environment, trust is no longer built at purchase but maintained over the product’s entire lifecycle. For gadget enthusiasts, evaluating a brand now means asking how it behaves when something goes wrong, not whether its logo once symbolized safety.

How Leading Brands Are Building Power Bank Ecosystems

Leading power bank brands in 2025 are no longer competing only on capacity or wattage. They are deliberately building ecosystems that connect hardware, software, accessories, and long-term trust into a single experience. **The power bank is positioned as a node within a broader energy ecosystem**, designed to reduce friction in daily use and increase switching costs for users.

Anker is the clearest example of this shift. According to analyses cited by major consumer electronics reviewers and teardown specialists, the Prime series integrates high-output PD 3.1 hardware with real-time telemetry, Bluetooth app control, and proprietary charging docks. This means users are not just charging devices; they are managing energy flows, monitoring battery health, and optimizing charging behavior over time. **The ecosystem value lies in continuity**, where the same app and dock support multiple future products.

CIO takes a different but equally strategic approach. By combining semi-solid-state batteries with ultra-thin industrial design, the company builds an ecosystem centered on portability and safety. Industry commentary from Japanese battery safety experts notes that structural safety choices enable slimmer enclosures and consistent thermal behavior. **CIO’s ecosystem is physical rather than digital**, where chargers, cables, and batteries share a unified size philosophy and tactile design language that encourages brand loyalty.

| Brand | Core Ecosystem Axis | User Value Created |

|---|---|---|

| Anker | App, display, dock integration | Energy visibility and control |

| CIO | Form factor and battery safety | Everyday carry optimization |

| Elecom | Longevity and disaster readiness | Long-term reliability and trust |

Elecom’s ecosystem strategy is anchored in time rather than convenience. With sodium-ion batteries rated for over 5,000 cycles, the company reframes ownership as a decade-long relationship. Coverage by technology journalists and battery researchers highlights how this durability aligns with Japan’s disaster-prevention culture and upcoming recycling mandates. **Here, the ecosystem extends beyond products to include disposal, compliance, and social responsibility**.

What unites these approaches is a clear departure from one-off product thinking. Leading brands are designing power bank ecosystems that reward continued use, shared standards, and predictable behavior. For highly engaged gadget users, this ecosystem logic increasingly matters as much as raw specifications.

Choosing the Right Power Bank for Work, Urban Life, or Emergencies

Choosing the right power bank in 2025 requires aligning technical characteristics with the realities of how and where you live and work. A device that feels perfect at a desk can become a burden in a commuter bag, while a lightweight model optimized for cafés may fail when infrastructure collapses. **The key is to treat a power bank as a role-specific energy tool rather than a universal accessory**, and to judge it through the lens of daily behavior and risk exposure.

For professional work in urban environments, output stability and protocol compatibility matter more than raw capacity. According to analyses from USB-IF contributors and charger testing labs such as ChargerLAB, modern laptops frequently spike above their nominal wattage during short bursts of CPU or GPU load. A power bank limited to older PD profiles may technically “charge” a laptop while still allowing its internal battery to drain. **PD 3.1 support with sufficient thermal headroom is therefore essential for work-focused users**, especially those relying on high-performance notebooks.

Urban life introduces a different constraint: friction. Carrying extra cables, thick enclosures, or oversized batteries directly reduces the likelihood that the power bank will be used at all. Behavioral research cited by design-focused manufacturers shows that devices exceeding roughly 250 grams are significantly less likely to be carried daily. In this context, thin enclosures enabled by semi-solid batteries and Qi2 magnetic alignment become decisive. **Convenience directly translates into real-world energy availability**, even if headline specifications appear modest.

Emergency and disaster scenarios invert these priorities entirely. Here, longevity, predictability, and environmental tolerance outweigh speed or compactness. Reports referenced by Japanese disaster-prevention agencies emphasize that many lithium-ion power banks fail not because of damage, but because they self-discharge during long storage. Sodium-ion chemistry, highlighted in coverage by technology analysts and materials researchers, addresses this weakness with exceptionally low degradation over time and reliable performance in sub-zero conditions.

The contrast between these use cases becomes clearer when viewed side by side.

| Primary Use Case | Critical Requirement | Technical Focus | Main Trade-off |

|---|---|---|---|

| Professional Work | Stable high output | PD 3.1 EPR, heat management | Weight and cost |

| Urban Daily Carry | Ease of use | Thin design, Qi2 alignment | Limited capacity |

| Emergency Preparedness | Long-term reliability | Sodium-ion chemistry, low self-discharge | Bulk and charging speed |

Another often-overlooked factor is regulatory and logistical compatibility. Aviation authorities in Japan and internationally increasingly scrutinize battery capacity and labeling, making borderline-capacity models inconvenient for frequent travelers. **Selecting a power bank comfortably below regulatory thresholds reduces cognitive and practical stress**, particularly for professionals who move between cities.

From a safety perspective, experts cited by certification bodies such as JQA and TÜV SÜD stress that compliance marks indicate baseline conformity, not absolute risk elimination. For work and urban use, advanced battery management systems and structural safety, as seen in semi-solid designs, reduce exposure during constant movement. For emergencies, chemical stability itself becomes the primary safety feature, especially when devices are stored unattended for years.

Ultimately, the right choice emerges from honest prioritization. If your livelihood depends on uninterrupted computing, prioritize controlled high output and protocol maturity. If your days revolve around mobility and spontaneity, favor designs that disappear into your routine. If resilience against the unexpected is the goal, accept size and weight in exchange for durability and time-proof reliability. **A well-chosen power bank does not just store energy; it aligns with the way you navigate modern life under both normal and extreme conditions.**

Extending Battery Life and Reducing Risk Through Proper Use

Extending the usable life of a modern power bank is no longer only about convenience but also about safety management. As mobile batteries have evolved into high-density energy devices capable of delivering over 100W, **daily handling practices now have a measurable impact on degradation speed and incident risk**. Research synthesized by the Electrochemical Society and battery safety groups consistently shows that user behavior can account for a significant portion of early capacity loss and thermal events.

At the core of battery aging are two stressors: heat and sustained high voltage. Lithium-ion chemistry, including advanced silicon-carbon anodes, degrades fastest when cells remain near full charge at elevated temperatures. According to analyses referenced by IEEE and major cell manufacturers, keeping batteries at 100 percent charge for prolonged periods accelerates electrolyte decomposition and electrode swelling, even in premium designs.

| Usage Condition | Impact on Battery Health | Risk Level |

|---|---|---|

| Stored at 100% charge | Accelerated chemical aging | Medium |

| Stored at 50–80% charge | Most chemically stable state | Low |

| Exposed to high heat | Rapid capacity loss, swelling | High |

In practical terms, this means a power bank should be treated less like a disposable accessory and more like precision equipment. **Avoid leaving it plugged in overnight after it has reached full capacity**, especially in warm environments such as near windows, inside cars, or on top of laptops. Even with intelligent charge controllers, residual trickle charging keeps internal voltage high, subtly shortening cycle life.

Another often overlooked factor is simultaneous charging and discharging, commonly called pass-through stress. While many modern power banks advertise pass-through capability, studies cited by UL Solutions indicate that continuous high-load pass-through use raises internal temperatures by double-digit percentages compared to single-direction charging. This is particularly relevant with USB PD 3.1 devices powering laptops, where sustained output above 60W creates cumulative thermal strain.

If a power bank feels uncomfortably hot to the touch, that heat is already beyond the optimal operating window. Temporarily stopping use at this stage significantly reduces long-term damage and lowers the probability of thermal runaway.

Charging speed selection also matters. Fast charging is safe within specification, but repeated rapid cycles do trade longevity for convenience. Battery University, operated by Cadex Electronics, notes that slower charging can meaningfully extend total cycle count, especially for high-density cells. When time allows, using a lower-wattage charger for topping up rather than maximum-speed input helps preserve internal structure.

Physical handling plays an equally critical role in risk reduction. Internal CT scan analyses published by industrial inspection firms show that many recalled batteries suffered from microscopic internal damage exacerbated by drops or compression inside bags. **Avoid placing power banks under heavy items or bending pressure**, and discontinue use immediately if swelling, unusual odor, or irregular charging behavior appears.

Finally, long-term storage deserves deliberate planning. For users rotating multiple power banks, seasonal or emergency units should be checked every few months and kept around half charge. This aligns with recommendations from major cell suppliers and aviation safety authorities, who emphasize that deeply discharged batteries are more likely to fail irreversibly or behave unpredictably when recharged.

By combining controlled charging habits, thermal awareness, and mindful storage, users can realistically double the functional lifespan of a quality power bank. More importantly, **these practices directly reduce the likelihood of the rare but serious failures that have driven stricter regulations worldwide**, making proper use not just a matter of efficiency, but of responsibility.

参考文献

- TechRadar:This is the world’s first sodium-ion mobile battery, a game changer in environmental sustainability, but it’s not cheap

- Chargerlab:Golden Charge Awards 2025 Announced: 17 Products Win the Technology Innovation Award

- Granite River Labs:How to be “Qi2 Ready” for the 2025 Wireless Charging Market

- CPSC:More than One Million Anker Power Banks Recalled Due to Fire and Burn Hazards

- Japan Today:Japanese airlines enacting new mobile battery carry-on rules this month

- Sustainability Directory:Japan Mandates Battery Recycling to Secure Critical Minerals and Boost Circularity