Have smartphones become heavier, thicker, and more excessive than they need to be? Many tech enthusiasts outside Japan are starting to ask this question as camera bumps grow larger and devices feel more like bricks than personal companions.

The rumored iPhone Air, also known as the iPhone 17 Slim, represents Apple’s bold attempt to reverse that trend by focusing on thinness, lightness, and everyday comfort without abandoning high-end performance.

This device is expected to arrive in late 2025 and could mark the most dramatic design shift in the iPhone lineup in over a decade.

Rather than competing on raw specs alone, Apple appears to be redefining what “premium” means by prioritizing how a phone feels in the hand, slips into a pocket, and integrates into daily life.

Engineering leaks point to a thickness of around 5.6mm, the use of advanced titanium alloys, new cooling systems like ultra-thin vapor chambers, and high-density silicon-carbon batteries.

These are not cosmetic tweaks but deep structural changes that challenge long-standing assumptions about durability, heat management, and battery life.

In this article, you will discover why Apple is shifting from the Plus model to the Air concept, how cutting-edge materials and physics make extreme thinness possible, and how this strategy positions Apple against foldable smartphones from Samsung, Xiaomi, and Honor.

If you care about smartphone design, engineering innovation, and where the global premium market is heading next, this deep dive will give you the context and insights needed to understand why the iPhone Air could become one of Apple’s most important products yet.

- From Plus to Air: Why Apple Is Rethinking Its iPhone Lineup

- The Global Market Shift Toward Experience Over Raw Specifications

- Competing on Thinness: iPhone Air vs Ultra-Thin Foldable Phones

- Structural Engineering at 5.6mm: How Apple Prevents Bending

- Titanium, Aluminum, and Hybrid Frames: Materials That Make Slim Possible

- Thermal Innovation: Vapor Chambers and Graphene Cooling Explained

- Display Breakthroughs: OLED TDDI and ProMotion in a Slim Body

- Battery Chemistry Evolution: Silicon-Carbon Cells and All-Day Power

- Camera Minimalism: Metalens Technology and Computational Photography

- Manufacturing and Supply Chain Challenges Behind an Ultra-Thin iPhone

- 参考文献

From Plus to Air: Why Apple Is Rethinking Its iPhone Lineup

For nearly a decade, Apple has expanded the iPhone lineup through additive evolution, offering larger screens, better cameras, and faster chips. However, recent sales performance suggests that this strategy has reached a point of diminishing returns. **The underwhelming reception of the iPhone 12 mini, followed by sluggish demand for the iPhone 14 Plus and 15 Plus, signaled a structural mismatch between product positioning and real user priorities**. According to long-term market tracking by Counterpoint Research and analysis cited by MacRumors, consumers did not reject large displays outright, but they became increasingly sensitive to weight, thickness, and everyday usability.

The Plus model was originally designed to democratize size, giving users a Pro Max–class display at a lower price. In practice, it inherited most of the physical compromises of the Pro Max without delivering a clearly differentiated experience. **As smartphone performance reached a saturation point, Apple began to recognize that “bigger” no longer automatically meant “better.”** This realization created the conditions for a conceptual pivot rather than a simple spec refresh.

| Lineup Concept | Core Value | User Trade-off |

|---|---|---|

| Plus | Large display at lower cost | Heavy body, weak differentiation |

| Air | Extreme thinness and comfort | Moderate camera hardware |

The iPhone Air concept borrows directly from the success of iPad Air. Apple executives have repeatedly framed iPad Air as the product for users who want premium design and performance without the complexity or cost of Pro features. **Translating this philosophy to the iPhone allows Apple to redefine “premium” around physical experience rather than raw specifications.** An ultra-thin body, rumored at around 5.6 mm, changes how the device feels in a pocket, in one-handed use, and in daily commuting scenarios.

This shift is also strategically defensive. Foldable smartphones from Samsung and Chinese manufacturers have reframed thinness as a symbol of technological leadership. Instead of adopting hinges and flexible displays, Apple appears to be responding with a purist approach: a single slab pushed to the limits of material science. **By replacing the Plus with Air, Apple is not shrinking its ambition but sharpening it, betting that the next phase of smartphone differentiation will be felt more in the hand than measured on a spec sheet.**

The Global Market Shift Toward Experience Over Raw Specifications

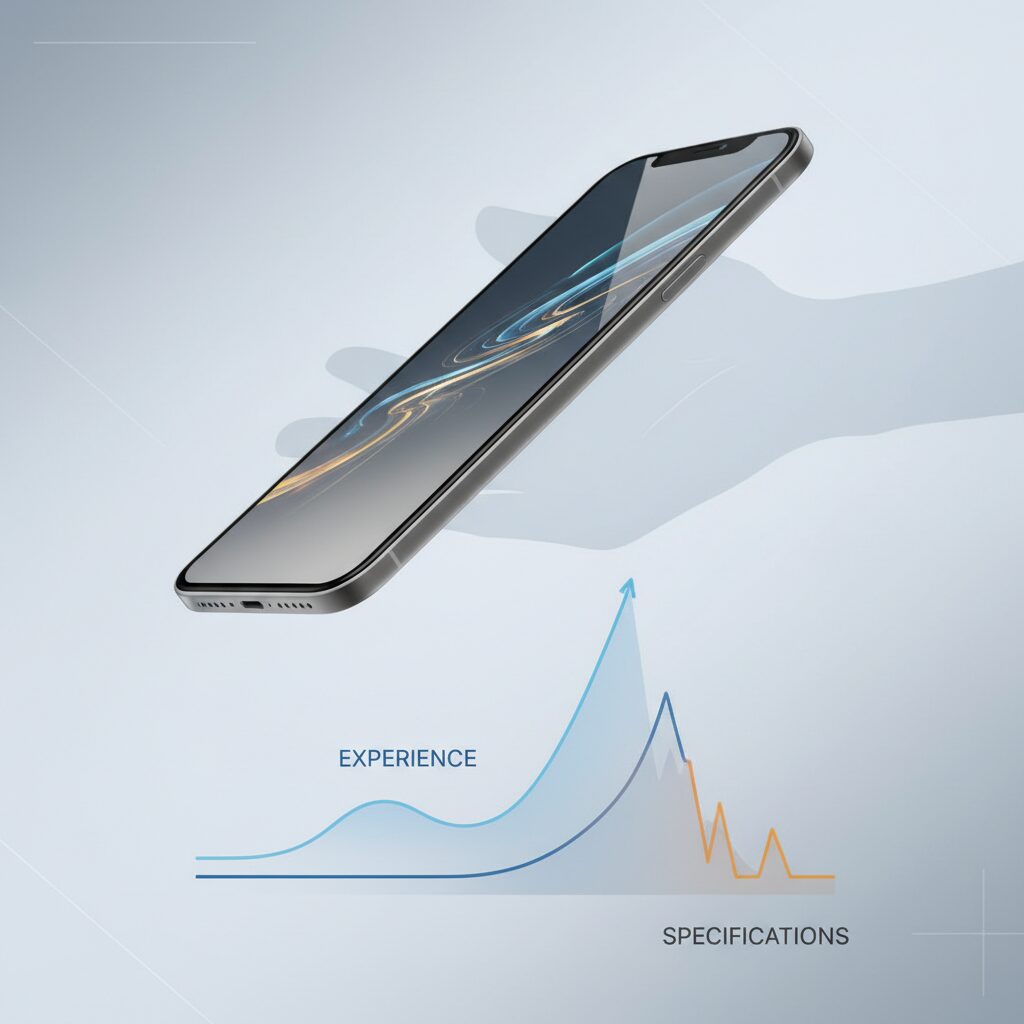

The global smartphone market is undergoing a clear transition from a race for raw specifications to a competition centered on holistic user experience. For more than a decade, performance metrics such as CPU benchmarks, multi-lens camera counts, and display size dominated marketing narratives. However, recent market signals suggest that these factors alone no longer guarantee commercial success, especially in mature premium segments.

Sales performance of recent iPhone lineups illustrates this shift with unusual clarity. According to analyses cited by Counterpoint Research, models positioned primarily around size expansion, such as the iPhone 14 Plus and iPhone 15 Plus, showed noticeably weaker demand compared with both standard and Pro variants. Despite offering larger displays and strong battery life on paper, these devices failed to create a compelling experiential identity for users.

This trend reflects a broader consumer recalibration. As smartphones have reached a point of functional saturation, incremental gains in processing power or camera resolution deliver diminishing emotional returns. Users increasingly evaluate devices based on how they feel in daily life: comfort during prolonged use, ease of one-handed operation, visual harmony of the design, and the absence of physical fatigue.

| Purchase Driver | Spec-Centric Era | Experience-Centric Era |

|---|---|---|

| Primary Appeal | Benchmarks and numbers | Usability and comfort |

| Design Priority | Maximizing components | Minimizing physical burden |

| Upgrade Motivation | Performance leaps | Quality of daily interaction |

Research by Japan’s Mobile Society Research Institute further supports this evolution. Its consumer surveys consistently show that usability and brand trust now outweigh pure hardware specifications in purchase decisions, particularly in markets where smartphones are deeply embedded into everyday routines. This aligns with insights from human-computer interaction studies published through ACM, which emphasize perceived effort and physical ergonomics as key determinants of long-term user satisfaction.

In this context, thinness and lightness are no longer cosmetic choices but experiential technologies. A reduction of even tens of grams or a few millimeters fundamentally changes how a device integrates into clothing, commuting, and prolonged handheld use. The product becomes less of a tool that demands attention and more of an unobtrusive extension of the body.

Apple’s strategic pivot toward an “Air” philosophy in smartphones can therefore be read as a response to this global market psychology. Rather than competing head-on in numerical superiority, the company appears to be prioritizing sensory and emotional value, redefining premium not by what is added, but by what is thoughtfully removed.

Competing on Thinness: iPhone Air vs Ultra-Thin Foldable Phones

The race for thinness has entered a new phase, and it is no longer limited to traditional slab smartphones. Ultra-thin foldable phones from Samsung and leading Chinese manufacturers have redefined expectations by achieving astonishing numbers when unfolded. Devices such as the Galaxy S25 Edge or Honor’s latest foldables reach between 4.3mm and 5mm, figures that would have been unthinkable for consumer smartphones just a few years ago.

However, it is important to understand that these measurements represent a very specific state: the fully opened form factor. When folded, these devices typically double in thickness and introduce a hinge, a mechanical compromise that fundamentally changes daily usability. **Apple’s iPhone Air challenges this narrative by pursuing extreme thinness in a single, uninterrupted slab**, without relying on hinges or flexible displays.

| Category | Ultra-Thin Foldables | iPhone Air |

|---|---|---|

| Measured Thinness | 4.3–5.0mm (unfolded) | Approx. 5.6mm (always) |

| Mechanical Parts | Hinge required | None |

| Daily Carry Feel | Thick when folded | Consistently slim |

From an engineering perspective, this distinction matters greatly. According to materials researchers and teardown analyses cited by MacRumors and Counterpoint Research, foldable devices must distribute stress around the hinge, which limits long-term durability and water resistance. **A monolithic design like iPhone Air allows structural rigidity to be optimized across the entire chassis**, rather than around a single vulnerable axis.

There is also a user-experience dimension that numbers alone cannot capture. Industry reviewers at outlets such as PhoneArena have repeatedly noted that ultra-thin foldables feel impressive in demos but less practical in motion-heavy daily life. A consistently thin phone, by contrast, disappears into pockets, jackets, and bags, a quality that resonates strongly in markets where portability is valued.

In this sense, Apple is not merely responding to foldables on their own terms. It is reframing the competition by asking a different question: not how thin a phone can become at one moment, but **how thin it feels every moment it is used**. That philosophical shift may ultimately matter more than winning a millimeter war on spec sheets.

Structural Engineering at 5.6mm: How Apple Prevents Bending

At just 5.6 mm thick, the greatest enemy of the iPhone Air is not heat or battery life, but bending. Apple’s engineers are acutely aware that ultra-thin phones are judged not only by elegance, but by whether they survive daily stress in pockets and bags. The memory of the iPhone 6 Plus “Bendgate” still shapes today’s design philosophy, and this model represents a deliberate response grounded in structural engineering rather than cosmetic fixes.

The core challenge lies in basic physics. Bending stiffness is governed by the product of material stiffness and the second moment of area, which decreases dramatically as thickness shrinks. Reducing thickness from around 8 mm to 5.6 mm would normally slash rigidity to a fraction of previous levels. According to mechanical engineering principles cited widely in academic literature, halving thickness can reduce bending resistance by nearly an order of magnitude if materials remain unchanged.

| Factor | Conventional iPhone | iPhone Air Approach |

|---|---|---|

| Frame material | Aluminum or stainless steel | Titanium alloy (Ti‑6Al‑4V) |

| Internal reinforcement | Discrete mid-plate | Hybrid bonded skeleton |

| Battery role | Energy storage only | Structural load-bearing element |

Apple addresses this by combining materials with complementary strengths. Analyst reports and patent filings suggest a titanium outer frame diffusion-bonded to an aluminum internal structure. Titanium’s high yield strength and elastic recovery allow the chassis to flex slightly under load and return to shape, rather than deform permanently. Aluminum inside redistributes stress and improves thermal behavior, creating a composite beam effect at smartphone scale.

Another quiet innovation is the battery itself. By moving from soft pouch cells to a rigid metal-can design, the battery becomes a structural block that resists torsion. In interviews reported by PCMag and other outlets, Apple executives have confidently challenged concerns about bending, pointing to internal stress testing that exceeds real-world pocket forces. The result is a device that feels impossibly thin, yet behaves mechanically like something much thicker.

Titanium, Aluminum, and Hybrid Frames: Materials That Make Slim Possible

Ultra-slim smartphones do not become thin by design alone; they become thin because materials science allows them to. In a device targeting an extreme thickness around 5.6 mm, the frame is no longer a passive shell but an active structural component. **The choice between titanium, aluminum, or a hybrid of both directly determines whether such slimness is even feasible** without repeating past failures like the iPhone 6 Plus bending issue.

Titanium alloys, particularly Ti-6Al-4V, have emerged as a key enabler. According to materials data referenced by aerospace and medical engineering standards, this alloy delivers a yield strength in the 800–900 MPa range, far exceeding the roughly 500 MPa typical of high-grade 7000-series aluminum. This matters because, as mechanical engineering textbooks from institutions such as MIT explain, bending resistance collapses rapidly as thickness decreases. **Higher specific strength allows designers to reclaim rigidity that thin geometry would otherwise destroy.**

| Material | Density | Yield Strength | Thermal Conductivity |

|---|---|---|---|

| Titanium Alloy (Ti-6Al-4V) | ~4.4 g/cm³ | 800–900 MPa | ~7 W/mK |

| Aluminum Alloy (7000 series) | ~2.8 g/cm³ | ~500 MPa | ~170 W/mK |

However, titanium is not a miracle material. Its thermal conductivity is an order of magnitude lower than aluminum, a fact well documented in peer-reviewed metallurgy journals. In a smartphone packed with a high-performance SoC, poor heat spreading would quickly lead to throttling. **This is where hybrid frames become not just clever, but necessary.**

Industry analysts and patent filings indicate that Apple is likely relying on diffusion bonding or clad structures, techniques already validated in aerospace manufacturing. In this approach, a titanium outer band forms a rigid exoskeleton that resists bending and impact, while an internal aluminum subframe manages heat flow and provides mounting precision for components. Because diffusion bonding joins metals at the atomic level, it avoids the weak interfaces that plagued earlier multi-material phones.

From a user’s perspective, this hybrid strategy solves three problems simultaneously. First, it preserves the premium tactile feel and scratch resistance associated with titanium. Second, it maintains thermal stability comparable to thicker aluminum devices. Third, it keeps weight in check; a full titanium body would be unnecessarily heavy, while a pure aluminum frame would struggle structurally at this thickness. **The result is a frame that behaves less like a casing and more like a load-bearing chassis.**

Commentary from Apple executives, reported by established technology outlets, has emphasized confidence in bend resistance despite the aggressive thinness. That confidence aligns with what materials engineers would predict from a titanium-aluminum hybrid: elastic deformation is tolerated, permanent deformation is resisted, and internal stresses are distributed more evenly. In practical terms, pockets, bags, and one-handed use no longer represent structural threats.

Ultimately, slimness at this level is not achieved by choosing the strongest or lightest metal in isolation. It is achieved by **orchestrating materials so that each compensates for the other’s weaknesses**. Titanium provides strength where geometry fails, aluminum restores thermal balance where titanium falls short, and hybrid bonding turns both into a single, coherent structure. Without this material symbiosis, a truly slim smartphone would remain a design sketch rather than a reliable product.

Thermal Innovation: Vapor Chambers and Graphene Cooling Explained

Thermal management is one of the most underestimated challenges in ultra-thin smartphones, and in a device as slim as the iPhone Air, it becomes a defining factor of real-world performance. As semiconductor scaling slows, raw chip efficiency alone is no longer enough. **How heat is absorbed, spread, and dissipated determines whether peak performance can be sustained or quickly throttled**.

The centerpiece of this approach is the adoption of an ultra-thin vapor chamber. According to analyses referenced by MacRumors and Mashable, Apple is expected to use a custom vapor chamber measuring roughly 0.3 to 0.4 millimeters in thickness. Despite its minimal profile, this structure leverages phase-change cooling, where a working fluid evaporates at hot spots and condenses in cooler regions, transporting heat far more efficiently than solid copper or graphite alone.

| Cooling Method | Heat Transport Mechanism | Relative Efficiency |

|---|---|---|

| Graphite Sheet | Solid-state conduction | Baseline |

| Vapor Chamber | Phase-change convection | Several times higher |

What makes Apple’s implementation particularly notable is the internal wick structure. Industry research highlighted by EurekAlert explains that sintered copper or micro-mesh wicks enable liquid return via capillary action, allowing consistent cooling regardless of device orientation. This is critical for a smartphone that is constantly tilted, pocketed, or used one-handed.

Complementing the vapor chamber is the expanded use of graphene sheets. Graphene’s in-plane thermal conductivity, often cited in materials science literature as reaching several thousand watts per meter-kelvin, allows heat to spread rapidly across the interior. **This is especially important because titanium frames, while strong, conduct heat poorly**, making internal heat equalization essential.

By distributing heat evenly toward the display and rear glass, the device effectively turns its entire surface into a passive heat sink. Performance-focused outlets such as AppleMagazine note that this combination can significantly delay thermal throttling during sustained workloads like 4K video editing or high-frame-rate gaming, bringing stability closer to Pro-class devices despite the dramatically thinner chassis.

In practical terms, this thermal architecture reflects a shift in Apple’s design philosophy. Instead of relying on brute-force thickness or larger heat spreaders, the company is optimizing heat flow at a systems level. For users, this means a thinner phone that does not merely look elegant, but also remains comfortable to hold and reliably fast under prolonged use.

Display Breakthroughs: OLED TDDI and ProMotion in a Slim Body

The display is where the iPhone Air’s extreme thinness becomes visually tangible, and Apple’s rumored adoption of OLED TDDI marks a quiet but critical breakthroughです。TDDI, or Touch and Display Driver Integration, consolidates what were traditionally separate control layers into a single silicon solution. According to supply-chain analysis reported by MacRumors, this integration can shave fractions of a millimeter off the display stack, a reduction that may sound trivial but is decisive when the total device thickness is targeted at around 5.6mmです。

From an engineering standpoint, TDDI does more than reduce thicknessです。By shortening signal paths between touch sensing and pixel driving circuits, it improves response consistency and lowers parasitic power loss. Semiconductor research groups tracking OLED driver evolution have noted that integrated architectures can cut display-side power consumption by several percentage points under mixed-use conditions. In a slim device with limited battery volume, this efficiency gain directly translates into longer real-world screen-on timeです。

| Aspect | Conventional OLED | OLED with TDDI |

|---|---|---|

| Driver structure | Separate touch and display ICs | Single integrated IC |

| Module thickness | Thicker multilayer stack | Noticeably reduced stack |

| Power efficiency | Baseline | Improved through shorter signal paths |

Equally significant is the expectation that Apple brings ProMotion to this ultra-thin form factorです。A 120Hz adaptive refresh rate has traditionally been reserved for Pro models, largely due to cost and power constraints. However, LTPO OLED technology allows the refresh rate to dynamically scale down to as low as 1Hz for static content. Display experts cited by Display Supply Chain Consultants have emphasized that LTPO is not just about smooth scrolling, but about enabling high refresh rates without a proportional increase in energy drawです。

The combination of TDDI and ProMotion changes the user experience in subtle but cumulative waysです。 Everyday interactions such as scrolling long articles, navigating maps, or editing photos feel fluid, while background power consumption remains tightly controlled. In a device designed around lightness and comfort, this balance is more important than raw brightness or resolution numbers aloneです。

Durability also benefits from this display strategyです。With fewer layers and interconnects, the panel becomes structurally simpler, reducing internal stress points. Apple’s continued use of Ceramic Shield glass, as noted in its materials briefings, means the display does not merely sit on the chassis but contributes to overall rigidity. In an ultra-slim body, the screen effectively becomes part of the structural system, reinforcing the idea that display technology here is as much about mechanical design as visual qualityです。

Seen as a whole, the iPhone Air’s display is not chasing headline specs but redefining efficiency per millimeterです。By integrating OLED TDDI with ProMotion in a remarkably thin stack, Apple appears to be prioritizing harmony between form, responsiveness, and endurance. This approach aligns with the company’s broader philosophy that the best display is not the one that shouts the loudest on a spec sheet, but the one that disappears into daily use while consistently feeling rightです。

Battery Chemistry Evolution: Silicon-Carbon Cells and All-Day Power

Achieving all-day battery life in an ultra-thin smartphone is not a matter of optimization alone but of chemistry. In a chassis approaching 5.6 mm, the traditional approach of increasing battery volume is no longer available, so Apple is widely expected to rely on a more fundamental shift in cell design. The focus is on silicon-carbon battery cells, a technology that has already demonstrated real-world viability in cutting-edge devices from Chinese manufacturers.

Conventional lithium-ion batteries use graphite as the anode material, a solution that has been refined for decades but is now nearing its theoretical limits. Silicon, by contrast, can store nearly ten times more lithium ions than graphite, a fact well established in electrochemistry research and frequently cited by institutions such as the U.S. Department of Energy. The challenge has always been silicon’s extreme volume expansion during charging, which leads to rapid degradation.

Silicon-carbon anodes address this by dispersing nano-scale silicon particles within a carbon matrix, allowing the structure to absorb expansion without catastrophic cracking. According to materials research published in leading journals like Nature Energy, this approach enables a practical energy density increase of roughly 10 to 20 percent compared with advanced graphite-based cells, without sacrificing cycle life.

| Anode Type | Relative Energy Density | Key Limitation |

|---|---|---|

| Graphite | Baseline | Near theoretical limit |

| Silicon-Carbon | +10–20% | Complex manufacturing |

For a device like iPhone Air, this gain translates directly into usability. Even with a physically smaller battery pack, projections indicate a capacity comparable to, or slightly exceeding, today’s standard iPhone models. Real-world examples strengthen this claim: the Honor Magic V3, cited by multiple independent teardowns, fits over 5,000 mAh of total capacity into an extremely constrained form factor by relying on high-silicon-content cells.

What makes this especially relevant is not peak capacity but endurance under typical daily loads. Apple’s strength has historically been system-level efficiency, and a denser battery chemistry compounds those gains. **A modest percentage increase in energy density can mean hours of additional screen-on time when paired with aggressive power management and LTPO displays**, a point Apple executives have emphasized in past discussions on battery strategy.

From a market perspective, this chemistry shift also signals maturity. Silicon-carbon cells are no longer experimental; they are entering mass production with improving yields. Analysts following the battery supply chain note that the technology has crossed a threshold where reliability is sufficient for premium smartphones, making it a logical choice for a flagship focused on thinness without compromise.

In this context, all-day power is not achieved by bending physics, but by rethinking it. Silicon-carbon batteries allow thin devices to escape the trade-off between elegance and endurance, and they may quietly become one of the most important enablers behind the iPhone Air’s promise of effortless, lightweight daily use.

Camera Minimalism: Metalens Technology and Computational Photography

Camera minimalism is not simply an aesthetic choice in the iPhone Air concept, but a direct response to the physical limits imposed by an ultra-thin chassis. To reduce camera protrusion while preserving imaging capability, Apple is expected to combine metalens technology with advanced computational photography, shifting value from optical bulk to algorithmic intelligence.

This approach reflects a broader industry trend observed by institutions such as MIT Media Lab and Nature Photonics, where flat optical elements are increasingly discussed as successors to conventional refractive lenses. **Metalens are fundamentally different from traditional curved lenses**, as they manipulate light through nanostructures rather than thickness.

Metalens are composed of arrays of nanoscale pillars, often made from materials like titanium dioxide or silicon nitride, fabricated using semiconductor lithography. According to peer-reviewed research from Harvard John A. Paulson School of Engineering and Applied Sciences, these structures can precisely control phase, polarization, and focal length within a layer thinner than one micrometer.

In practical terms, this means that components traditionally requiring multiple stacked lens elements can be collapsed into a single, flat optical surface. For the iPhone Air, this is particularly relevant for Face ID modules and potentially for future rear-camera optics, where depth is the primary constraint rather than sensor size.

| Aspect | Conventional Lens Stack | Metalens-Based Optics |

|---|---|---|

| Physical thickness | Several millimeters with multiple elements | Sub-millimeter flat structure |

| Manufacturing method | Precision molding and assembly | Semiconductor lithography |

| Design flexibility | Limited by curvature and alignment | Programmable at nanoscale |

However, metalens alone do not solve all optical challenges. Current implementations still face limitations in broadband performance and light efficiency, especially in low-light photography. This is where computational photography becomes inseparable from the hardware strategy.

Apple has spent more than a decade refining computational imaging, from Smart HDR to Deep Fusion and Photonic Engine. With a single high-resolution sensor, likely 48 megapixels, the iPhone Air can rely on sensor cropping, multi-frame fusion, and neural-network-based super-resolution to simulate versatility that once required multiple lenses.

According to imaging research published by IEEE and commentary from former Apple camera engineers, **modern smartphone image quality is now more constrained by signal processing than by optics alone**. By capturing multiple frames with slight hand-induced motion, the Neural Engine can reconstruct fine detail beyond the native optical resolution.

This strategy aligns with Apple’s silicon advantage. The A-series Neural Engine performs trillions of operations per second, enabling real-time depth estimation, semantic segmentation, and noise reduction. As a result, portrait effects, 2x lossless zoom, and even night photography remain viable without adding physical camera modules.

The essence of camera minimalism is not reduction, but reallocation: less glass and metal, more computation and perception.

From a user perspective, this translates into a cleaner back design, improved pocketability, and fewer compromises in daily photography. While it may not satisfy users who prioritize long-range optical zoom, it strongly appeals to those who value design coherence and consistent image quality.

By integrating metalens research with computational photography, Apple positions the iPhone Air as a statement device. It suggests that the future of smartphone cameras is not defined by how many lenses are visible, but by how intelligently light and data are interpreted together.

Manufacturing and Supply Chain Challenges Behind an Ultra-Thin iPhone

Building an ultra-thin iPhone is not only an engineering challenge but also a manufacturing and supply chain test at an unprecedented scale. **When thickness is reduced to around 5.6 mm, even minor deviations in component tolerances can cascade into yield losses**, making mass production far more complex than with conventional designs.

One of the most critical constraints comes from the logic board. According to multiple supply chain reports cited by MacRumors and AppleInsider, Apple initially explored resin-coated copper boards to reduce thickness. However, durability issues and low yields during drop and thermal cycling tests forced Apple to abandon this approach. As a result, suppliers must continue using established PCB processes while compensating elsewhere, which raises assembly difficulty and cost.

| Manufacturing Area | Key Challenge | Supply Chain Impact |

|---|---|---|

| Logic board | Limited thickness reduction | Higher part density, lower yields |

| Display module | New TDDI integration | Dependence on Novatek ramp-up |

| Chassis materials | Titanium-aluminum bonding | More complex machining steps |

The display supply chain introduces another layer of risk. The adoption of OLED TDDI technology supplied by Novatek reduces thickness and power consumption, but it also shifts part of Apple’s dependence away from long-established partners like Samsung Display. Industry analysts note that early production phases with new display drivers often suffer from yield instability, which can constrain launch volumes in the first months.

Chassis manufacturing is equally demanding. Titanium alloy frames require slower CNC machining and stricter quality control than aluminum. When combined with diffusion bonding to aluminum internal structures, **each unit passes through more processing stages**, increasing cycle time per device. According to manufacturing experts interviewed by PCMag, this complexity is one reason Apple executives remain cautious about production scale in the early ramp.

Finally, logistics and final assembly must adapt. Thinner batteries and denser internal layouts leave little room for rework at the factory level. Foxconn and other assemblers reportedly rely on more in-line optical inspection and AI-assisted defect detection to prevent small misalignments from reaching the market. **This shift reflects Apple’s broader strategy: fewer physical allowances, compensated by tighter supply chain discipline and process control**, as emphasized in analyses by Counterpoint Research.

参考文献

- MacRumors:iPhone Air: Everything We Know

- PhoneArena:Honor Magic V3 Review: Thin as a pancake!

- Mashable:iPhone 17’s new vapor chamber fixes overheating problem

- MacRumors:This Technology Could Pave the Way for the ‘iPhone 17 Air’ Next Year

- AppleInsider:iPhone 17 Air may debut advanced silicon battery for more efficient charging

- Semiconductor Insight:Apple’s iPhone 17 Rumored to Feature Metalens Technology for Face ID and Slimmer Bezels