For more than a decade, applying a screen protector has been almost a ritual for smartphone buyers. The fear of scratches, cracks, and costly repairs has shaped consumer behavior worldwide, turning thin sheets of tempered glass into a billion-dollar accessory market.

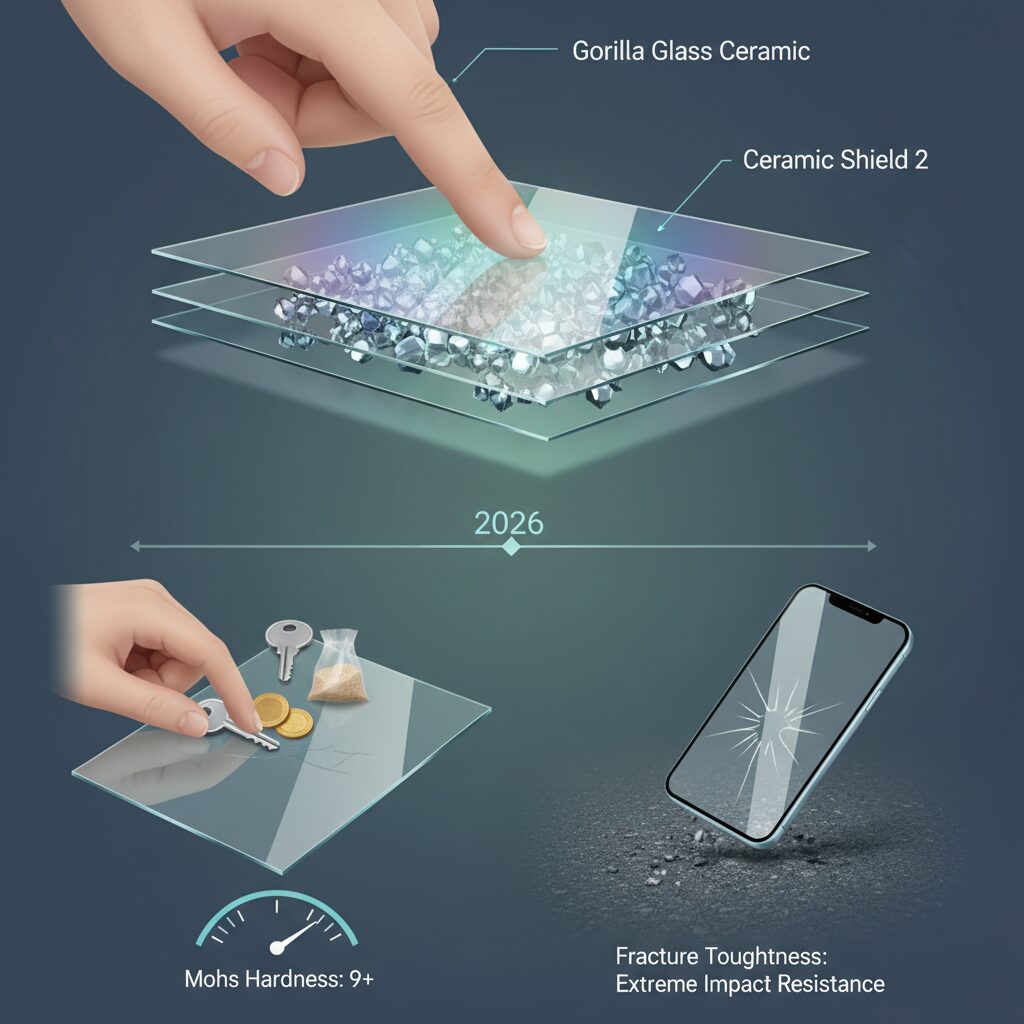

However, 2026 marks a turning point. With the arrival of Corning’s Gorilla Glass Ceramic and Apple’s Ceramic Shield 2, flagship smartphones now feature materials engineered with glass-ceramic hybrids, nanometer-scale anti-reflective coatings, and dramatically improved fracture resistance. Devices can reportedly survive repeated drops onto asphalt and resist scratches from keys and coins that once left permanent marks.

At the same time, data shows that traditional screen protectors can double surface reflectivity and significantly reduce outdoor visibility, effectively downgrading the display quality users paid premium prices for. Combined with evolving warranty programs such as AppleCare+ and shifting resale market dynamics, the logic of “always use a screen protector” is being fundamentally challenged. In this article, you will discover the science, economics, and real-world user data behind the emerging filmless era—and whether going without a screen protector truly makes sense for you in 2026.

- Why 2026 Is a Turning Point for Smartphone Display Protection

- Gorilla Glass Ceramic: The Science Behind 10 Consecutive Asphalt Drops

- Ceramic Shield 2 on iPhone 17: Triple Scratch Resistance Explained

- Mohs Hardness, Fracture Toughness, and What They Mean in Daily Use

- Anti-Reflective Coatings and the Physics of Light Interference

- How Screen Protectors Increase Reflectivity and Reduce Outdoor Visibility

- User Survey Data: Why a Growing Segment Is Going Filmless

- Resale Value vs. Real-World Scratch Probability in Mature Secondary Markets

- Repair Costs, AppleCare+, and the New Risk-Return Calculation

- Case Design, Raised Lips, and Alternative Protection Strategies

- Liquid Coatings and Oleophobic Layer Maintenance: Benefits and Limits

- The Future of Self-Healing Glass and Post-Protector Materials Innovation

- 参考文献

Why 2026 Is a Turning Point for Smartphone Display Protection

In 2026, smartphone display protection is no longer a simple question of “film or no film.” It is a structural turning point driven by material science, optical engineering, and changing consumer economics. What used to be a defensive habit is now being re-evaluated under measurable performance data.

The biggest catalyst is the rapid evolution of glass-ceramic technology. Corning’s Gorilla Glass Ceramic, introduced to flagship Android devices from late 2025, combines the processability of aluminosilicate glass with ceramic-like crystal structures that physically slow crack propagation. According to Corning’s published testing data, devices equipped with this material survived up to 10 consecutive drops from one meter onto asphalt-like surfaces.

| Material Generation | Drop Resistance (1m, Asphalt) | Structural Feature |

|---|---|---|

| Conventional Strengthened Glass | High probability of failure on first drop | Ion-exchanged surface compression |

| Gorilla Glass Ceramic (2025–2026) | Up to 10 consecutive drops survived | Embedded micro-crystals inhibiting crack growth |

Apple’s Ceramic Shield 2, introduced with the iPhone 17 series, further signals this shift. Scratch resistance has reportedly tripled compared to the previous generation, and hardness now approaches Mohs level 7–8 under typical conditions. Long-term hands-on reviews over three months have reported no visible hairline scratches under microscopic inspection.

This means everyday threats—keys, coins, quartz particles in dust—are no longer automatically fatal to your display. The baseline durability of premium smartphones has fundamentally changed.

Optical performance is the second driver of this turning point. Modern anti-reflective coatings, such as those applied to recent flagship devices, rely on nanometer-scale interference layers. These coatings are optimized for direct exposure to air. Independent reflection testing reported that an iPhone 17 Pro in bare condition measured around 2.0% reflectance, roughly half of older models.

However, when a standard tempered glass protector is applied, measured reflectance rises to approximately 4.6%. In practical terms, that can reduce outdoor visibility scores from near-perfect levels to below older-generation devices. For the first time, adding protection can measurably downgrade display performance.

This technological leap intersects with economic logic. In Japan, resale value has historically justified film usage, as minor scratches could reduce buyback prices by 15–30% depending on grading standards, according to major secondary market criteria. Yet if modern glass significantly lowers the probability of visible damage under normal use, the cost-benefit balance shifts.

At the same time, warranty ecosystems have matured. With services such as AppleCare+, front display repairs can cost a fixed, relatively low fee compared to out-of-warranty replacements. This reduces the catastrophic financial risk that once made screen protectors feel mandatory.

In short, 2026 represents a convergence point. Material durability has crossed a psychological threshold, optical engineering penalizes unnecessary layering, and risk mitigation has moved from physical barriers to service-based models. The industry has quietly entered the “post-mandatory film” era.

The debate is no longer about fragility. It is about optimization—visual purity, tactile fidelity, and rational risk management in a world where glass is stronger than ever before.

Gorilla Glass Ceramic: The Science Behind 10 Consecutive Asphalt Drops

Corning’s Gorilla Glass Ceramic represents a fundamental leap in display materials science, not just an incremental upgrade. Announced in March 2025 and rapidly adopted in 2026 flagship Android devices, this hybrid material fuses the processability of aluminosilicate glass with the mechanical resilience of ceramics. The result is a transparent glass-ceramic engineered at the microscopic level to resist catastrophic failure.

The key innovation lies in its controlled crystallization process. During manufacturing, a precise heat treatment grows nano-scale crystals within the glass matrix. According to Corning’s technical disclosures, these embedded crystals act as barriers that deflect and blunt crack propagation. Instead of allowing a crack to travel freely across the panel, the internal structure dissipates stress energy in multiple directions, dramatically increasing fracture resistance.

Mechanically, this translates into measurable performance gains over conventional strengthened glass.

| Property | Conventional Aluminosilicate Glass | Gorilla Glass Ceramic (2025–2026) |

|---|---|---|

| Fracture Behavior | Crack propagates linearly once initiated | Crack deflected and slowed by crystal phase |

| Asphalt Drop Test (1m) | High probability of failure on first drop | Survives 10 consecutive drops |

| Surface Rough Impact | Vulnerable to 180-grit equivalent texture | Engineered to withstand repeated contact |

The “10 consecutive asphalt drops” claim is particularly significant. Asphalt is far more aggressive than laboratory steel plates because it concentrates force onto sharp, irregular aggregates—roughly equivalent to 180-grit sandpaper. In real-world terms, this simulates the worst-case urban accident: a waist-high drop onto a coarse roadway. Surviving ten repeated 1‑meter drops under these conditions suggests not marginal improvement, but a structural redesign of failure mechanics.

Early deployments in Motorola’s next-generation devices demonstrated this resilience under controlled testing conditions. Industry observers note that previous generations typically fractured on the first or second impact against rough concrete. The new ceramic-reinforced matrix shifts the durability curve, meaning that everyday “oops” moments—slipping from a pocket, falling off a café table—are statistically far less likely to end in spiderweb cracks.

From a materials science perspective, the breakthrough is not simply hardness. Traditional thinking equated screen strength with surface hardness alone. Gorilla Glass Ceramic instead optimizes fracture toughness—resistance to crack growth—arguably the more critical metric in drop scenarios. By combining elastic energy absorption with crack deflection, the material behaves less like brittle glass and more like a controlled composite.

For gadget enthusiasts, this matters because it changes the baseline assumption of fragility. A display engineered to endure ten consecutive asphalt impacts fundamentally redefines what “normal use” durability means in 2026. It signals that the weakest point in a modern flagship smartphone is no longer automatically the front glass, but potentially other structural components. That shift in hierarchy is the true scientific story behind Gorilla Glass Ceramic.

Ceramic Shield 2 on iPhone 17: Triple Scratch Resistance Explained

The introduction of Ceramic Shield 2 on the iPhone 17 series marks a decisive leap in scratch resistance, redefining what everyday durability means for flagship smartphones in 2026. Compared with the previous generation, Apple has improved scratch resistance by a factor of three, according to industry coverage and early hands-on analyses. This is not a minor iteration; it reflects a material-level redesign that directly addresses the micro-abrasions users experience from keys, coins, and quartz particles in dust.

At the core of Ceramic Shield 2 is an advanced glass-ceramic structure. By embedding nano-scale crystalline structures within the glass matrix, crack initiation and propagation become significantly more difficult. Materials science research has long shown that controlled crystallization increases resistance to surface deformation. In practical terms, this means that objects previously capable of leaving faint hairline marks now fail to penetrate the surface layer under normal daily pressure.

Scratch resistance is commonly discussed in terms of Mohs hardness. While earlier smartphone glass typically began showing visible scratches at level 6 to 7, reports on Ceramic Shield 2 indicate resistance extending into level 7 to 8, and in specific controlled conditions approaching level 9. This places it in a category where common steel objects are no longer a serious threat.

| Material Interaction | Previous Ceramic Shield | Ceramic Shield 2 |

|---|---|---|

| Steel key contact | Possible micro-scratches over time | No visible scratches under normal use |

| Quartz dust (pocket sand) | Hairline marks possible | Significantly reduced risk |

| 3-month “bare” usage test | Minor surface wear reported | No microscopic hairlines observed |

One of the most compelling data points comes from extended real-world usage reviews. In a three-month “bare screen” evaluation of the iPhone 17 Pro, close-up and even microscopic inspections reportedly found no visible hairline scratches. This contrasts with earlier generations such as the iPhone 15 and 16, where subtle abrasions would accumulate without users noticing until light hit the display at certain angles.

Triple scratch resistance does not simply mean fewer visible marks; it changes user behavior. When users no longer worry about placing their device face-down on a clean desk or slipping it into a pocket without a dedicated sleeve, the psychological burden shifts. The screen becomes a resilient interface rather than a fragile liability.

From a physics standpoint, scratching occurs when a harder material plows through a softer surface, causing plastic deformation. By raising effective surface hardness and improving fracture toughness, Ceramic Shield 2 resists both indentation and crack extension. This dual improvement is critical. A harder surface alone can still be brittle, but combining hardness with improved toughness ensures that minor contact does not evolve into visible surface damage.

Quartz, commonly found in sand and dust, ranks around 7 on the Mohs scale. In everyday life, this is the hidden enemy of smartphone screens. Pocket lint mixed with fine mineral particles has historically been responsible for many unexplained scratches. By pushing resistance beyond this threshold, Apple effectively neutralizes one of the most common real-world abrasion sources.

It is also important to distinguish scratch resistance from shatter resistance. While both relate to durability, they address different failure modes. Ceramic Shield 2 improves scratch resistance by three times and reportedly enhances rear glass crack resistance by four times compared to the previous generation. This balanced evolution suggests a comprehensive materials engineering approach rather than a single-property optimization.

For gadget enthusiasts who scrutinize display clarity under direct sunlight or bright indoor lighting, micro-scratches are more than cosmetic. Even faint abrasions scatter light, reducing perceived contrast and increasing glare. By minimizing the formation of these microscopic defects, Ceramic Shield 2 helps maintain optical integrity over time. The result is not just a pristine look on day one, but sustained visual performance months into ownership.

In 2026, triple scratch resistance represents a structural shift toward “film-less confidence.” Instead of relying on external protective layers to absorb daily wear, the display itself becomes the primary defense mechanism. This approach aligns with broader industry trends in advanced glass-ceramic engineering, where intrinsic material strength replaces accessory-based mitigation.

For users deeply invested in performance, design purity, and long-term value retention, Ceramic Shield 2 delivers measurable reassurance. It addresses the most common surface-level damage vectors while preserving the tactile and optical qualities of the original display. In practical daily scenarios—keys in pockets, dust in bags, or desk placement—what once posed a visible risk now becomes statistically negligible under normal conditions.

Mohs Hardness, Fracture Toughness, and What They Mean in Daily Use

When evaluating modern smartphone glass, two scientific indicators deserve close attention: Mohs hardness and fracture toughness.

These terms may sound academic, but they directly determine whether your display resists everyday scratches or survives an unexpected drop.

Understanding the difference between them helps you judge real-world durability beyond marketing slogans.

Mohs hardness measures scratch resistance, while fracture toughness measures crack resistance.

The Mohs scale ranks materials from 1 (talc) to 10 (diamond) based on their ability to resist scratching by harder substances.

Fracture toughness, expressed in MPa√m, indicates how well a material can prevent a crack from spreading once damage begins.

| Property | What It Resists | Daily-Life Example |

|---|---|---|

| Mohs Hardness (Level 7–8) | Surface scratches | Keys, coins, quartz in dust |

| High Fracture Toughness | Crack propagation | Dropping onto asphalt |

For daily users, Mohs hardness answers a simple question: will my screen get scratched in my pocket?

Quartz, commonly found in sand and dust, ranks at level 7 on the Mohs scale.

If a display glass withstands level 7 or higher, it effectively resists scratches from most environmental particles.

According to reports on Ceramic Shield 2 and Gorilla Glass Ceramic, recent flagship devices reach Mohs level 7–8, and in controlled conditions approach level 9.

This means ordinary steel keys or coins cannot scratch the surface under normal contact.

As several long-term user reviews have shown, even after months of “naked” use, visible hairline scratches are often absent.

However, hardness alone does not prevent shattering.

A material can be extremely hard yet brittle, meaning it resists scratches but cracks easily when dropped.

This is where fracture toughness becomes critical.

Corning explains that glass-ceramic structures embed microscopic crystals within the glass matrix.

These crystals interrupt crack propagation, effectively stopping a small fracture from expanding across the panel.

In practical terms, higher fracture toughness transforms a drop from a catastrophic failure into a survivable event.

Real-world drop tests cited for Gorilla Glass Ceramic demonstrate survival after repeated 1-meter drops onto asphalt-like surfaces.

Asphalt is particularly aggressive because of its rough, quartz-rich texture.

Performance under such conditions signals meaningful resilience in daily commuting scenarios.

The key insight is that scratches and cracks originate from different physical mechanisms.

Scratches occur when a harder particle plows into the surface.

Cracks occur when stress exceeds the material’s ability to absorb and redistribute energy.

For users, this translates into two behavioral implications.

Avoiding sandy environments protects against level-7 abrasives.

Using a well-designed case with raised edges reduces impact stress concentration during drops.

Ultimately, Mohs hardness protects your screen’s appearance, while fracture toughness protects its structural survival.

Modern flagship glass has improved significantly in both metrics.

When you understand what each number truly represents, you can make informed decisions about how much additional protection you realistically need.

Anti-Reflective Coatings and the Physics of Light Interference

Anti-reflective (AR) coatings are not marketing decoration; they are precise optical structures engineered at the nanometer scale. When you understand the physics behind them, you begin to see why adding a generic screen protector can fundamentally alter what your display is capable of delivering.

At its core, reflection happens because light encounters a boundary between two media with different refractive indices. When light travels from air (refractive index ≈ 1.0) into glass (typically around 1.5), roughly 4% of the incident light is reflected at each interface under normal incidence. This is basic Fresnel physics, taught in standard optics textbooks and referenced by institutions such as MIT’s OpenCourseWare in their electromagnetism and optics materials.

AR coatings reduce this reflection by exploiting destructive interference. Instead of allowing reflected waves to reinforce each other, they are engineered so that reflected light waves cancel out.

How Destructive Interference Works

Modern smartphone AR coatings use ultra-thin layers whose thickness is typically designed around one-quarter of the target wavelength of visible light. When light reflects off the top surface of the coating and the interface beneath it, the two reflected waves are shifted in phase.

If the optical thickness is precisely tuned, the two reflected waves are 180 degrees out of phase. The result is destructive interference: the peaks of one wave align with the troughs of the other, canceling each other out and dramatically reducing net reflection.

In advanced implementations such as those described for Galaxy S24 Ultra’s Gorilla Armor and Apple’s latest Pro models, multiple layers are stacked to broaden the wavelength range over which this cancellation is effective. This is why reflections are suppressed not just for a narrow color band, but across much of the visible spectrum.

| Interface Condition | Typical Reflectance | Visual Impact |

|---|---|---|

| Air → Glass (no AR) | ~4% | Noticeable glare outdoors |

| Single-layer AR optimized | ~2% or lower | Significantly improved contrast |

| Multi-layer AR stack | ≈2% across wider spectrum | High clarity under strong light |

According to reported reflection tests on recent flagship models, reflectance values around 2.0% have been observed in optimized configurations. Cutting reflection roughly in half compared to older 3.8%–4% displays does not merely change brightness; it directly enhances perceived contrast ratio in bright environments.

Lower reflectance increases effective contrast because less ambient light is scattered back to the viewer. In outdoor use, this can be the difference between washed-out blacks and legible shadow detail.

The physics also explains why adding a conventional glass or PET protector often degrades performance. The AR system is calibrated for an air–coating boundary. Introducing an adhesive layer and another glass sheet creates additional interfaces, each with its own refractive index mismatch.

Each new boundary reintroduces Fresnel reflections. Even if small individually, they accumulate. More critically, the original destructive interference condition is disrupted because the phase relationships were optimized for a specific optical stack thickness.

This is not a subjective preference issue; it is wave optics. When you alter the stack, you alter the interference pattern. As a result, glare increases, contrast drops, and the display’s carefully tuned optical engineering is partially undone.

For gadget enthusiasts who value display fidelity, understanding AR coatings through the lens of interference physics reframes the discussion. The screen is no longer just hardened glass; it is a finely balanced optical system, where nanometer-scale layers determine whether light is canceled—or allowed to blind you.

How Screen Protectors Increase Reflectivity and Reduce Outdoor Visibility

Modern flagship smartphones are engineered with advanced anti-reflective (AR) coatings that assume direct contact between air and glass. When you apply a screen protector, you fundamentally alter that optical design.

This additional layer changes how light enters, reflects, and exits the display, often increasing total reflectivity and degrading outdoor visibility.

According to optical physics principles referenced in manufacturer documentation, light reflecting at each interface accumulates. A bare display with advanced AR coating can reduce reflectance to around 2.0%, but adding untreated glass on top reintroduces higher surface reflection.

| Device Condition | Measured Reflectivity | Outdoor Visibility Score (10 max) |

|---|---|---|

| iPhone 17 Pro (bare) | 2.0% | 9.8 |

| iPhone 17 (bare) | 2.1% | 9.5 |

| iPhone 17 (with standard glass protector) | 4.6% | 6.0 |

The numbers reveal a critical shift. Once a standard tempered glass protector is installed, reflectivity can more than double. In practical terms, this means more glare under direct sunlight and reduced contrast in high-brightness environments.

Independent reflection tests reported in late 2025 showed that a protected iPhone 17 could appear less readable outdoors than an unprotected device from two generations earlier.

The protector effectively cancels out part of the premium optical engineering users paid for.

The mechanism is straightforward. First, the adhesive layer between the protector and display introduces refractive index mismatch, disrupting the destructive interference pattern created by multi-layer AR coatings. Second, most third-party protectors lack comparable nano-scale interference coatings, allowing roughly 4% surface reflection at the outermost layer.

This creates multiple reflection boundaries: air-to-protector, protector-to-adhesive, adhesive-to-display. Each boundary contributes to cumulative glare.

In bright outdoor scenarios such as beach use or urban midday sunlight, that additional glare forces users to increase brightness, accelerating battery drain and thermal load.

Samsung’s anti-reflective glass implementation and Apple’s latest coating strategy are optimized at the nanometer scale. These systems are not simply “hard glass,” but carefully tuned optical stacks. When covered with conventional protectors, the optical stack no longer interfaces with air as designed.

The result is reduced perceived contrast, washed-out blacks, and stronger mirror-like reflections of the user’s surroundings.

For users focused on photography, HDR video playback, or color-critical editing, even small increases in reflectivity can meaningfully alter viewing accuracy.

There is also a psychological factor. Many users interpret glare as lower display quality, even if resolution and peak brightness remain unchanged. In side-by-side outdoor comparisons, reflections often dominate perception more than pixel density or refresh rate.

As high-end devices approach near-tablet brightness levels with LTPO and tandem OLED panels, optical purity becomes part of the premium experience.

Adding a basic protector may preserve scratch resistance, but it often does so at the cost of outdoor clarity and visual depth.

For gadget enthusiasts who prioritize maximum readability under harsh light, understanding this reflectivity increase is essential before applying any additional glass layer.

User Survey Data: Why a Growing Segment Is Going Filmless

Why are more users deliberately choosing to go without screen protectors in 2026? The answer becomes clear when we look at recent survey data and behavioral trends. According to ITmedia Mobile’s large-scale reader survey with 4,286 valid responses, 17% of users reported not using any physical screen protector, while an additional 6% relied only on coating solutions. In other words, nearly one in four users has already stepped away from traditional film-based protection.

This shift is not random. It reflects a measurable change in priorities among tech-savvy consumers who understand the evolution of modern display materials.

| User Choice (Japan, 2025–2026) | Percentage |

|---|---|

| Using film or glass protector | 76% |

| No protector | 17% |

| Coating only | 6% |

The most frequently cited reason is performance preservation. Respondents explained that they do not want to compromise touch sensitivity, swipe smoothness, or in-display fingerprint accuracy. With devices now equipped with advanced materials such as Ceramic Shield 2 and Gorilla Glass Ceramic, many users believe the native surface already delivers sufficient durability.

For this growing segment, adding a film feels less like protection and more like performance downgrading.

Another key factor is optical quality. As reported in reflection testing data, attaching a standard glass protector can increase reflectivity to 4.6%, compared to approximately 2.0% on a bare iPhone 17 Pro. Users who prioritize outdoor visibility and contrast perceive this difference immediately. In enthusiast communities such as Reddit, long-term “naked use” reviews frequently report no visible scratches after several months, reinforcing confidence in the underlying glass technology.

Design integrity also plays a psychological role. Survey comments highlight a desire to preserve the thinness, curved edges, and material harmony of titanium frames and edge displays. For minimalists and premium-device buyers, covering engineered glass with an aftermarket layer contradicts the product’s intended experience.

Trust in technology has become a decisive variable. As Corning publicly demonstrated multi-drop asphalt resistance in its ceramic glass, and as Apple emphasizes improved scratch resistance in its latest generation, users increasingly rely on manufacturer-backed durability claims rather than third-party accessories.

The emerging mindset is clear: if the display is engineered to survive real-world use, extra layers are no longer mandatory but optional.

This does not mean risk tolerance has disappeared. Rather, it has become calculated. Many film-free users pair their choice with careful habits—avoiding pockets with keys or coins, using protective cases with raised lips, and subscribing to device insurance programs. The survey data suggests that going filmless is less about carelessness and more about informed confidence.

In short, the growth of the filmless segment is driven by measurable improvements in materials science, visible optical trade-offs caused by protectors, and a consumer base increasingly willing to trust flagship-level engineering. The data indicates not rebellion against protection, but a rational reassessment of necessity.

Resale Value vs. Real-World Scratch Probability in Mature Secondary Markets

In mature secondary markets such as Japan, resale value is often the single strongest argument for applying a screen protector. Many buyers calculate total cost of ownership from day one, assuming they will resell the device in two to three years. However, in 2026, the gap between perceived scratch risk and real-world scratch probability has narrowed dramatically due to advances like Ceramic Shield 2 and Gorilla Glass Ceramic.

According to IOSYS’ official grading criteria, an “A rank” device must show virtually no visible scratches, while minor surface flaws can push a device into B or C rank, typically reducing buyback value by around 15% to 30%. This rule has historically justified the preventive use of films. Yet the key question is no longer how harsh the grading system is, but how likely it is for modern glass to accumulate resale-impacting scratches under normal use.

| Factor | 2020–2023 Devices | 2026 Flagships |

|---|---|---|

| Typical scratch onset | Mohs level 6–7 | Mohs level 7–8 or higher |

| Everyday key/coin damage | Common micro-scratches | Rare under normal separation |

| 3-year A-rank probability | Uncertain without film | High with basic care |

Expert long-term reviews of iPhone 17 Pro units using Ceramic Shield 2 have reported no visible hairline scratches after three months of film-less use, even under close inspection. Community discussions on Reddit echo similar outcomes when users avoid storing phones with quartz-containing debris or sharp minerals. In other words, the dominant causes of resale-damaging scratches are no longer coins or keys, but rare contact with harder materials such as sand or construction dust.

This distinction matters economically. If a high-end device loses, for example, 20% of its resale value due to visible scratches, the potential loss may amount to several tens of thousands of yen. However, if the statistical likelihood of such scratches occurring under ordinary urban use is now very low, the expected monetary loss decreases substantially. The calculation shifts from worst-case thinking to probability-weighted reasoning.

Moreover, buyers in 2026 are increasingly aware of improved materials. A device marketed with Gorilla Glass Ceramic or advanced anti-reflective coatings carries an implicit expectation of durability. As a result, minor, non-visible wear that does not affect display clarity may have less psychological impact on resale negotiations than in previous generations.

Therefore, for users who practice basic handling discipline—separate pockets, protective case lips, and proper cleaning as recommended by Apple—the probability of falling from A rank to B rank purely due to screen scratches appears significantly lower than historical norms. In such environments, resale value protection is no longer an automatic justification for optical compromise, but a calculated choice based on lifestyle risk exposure rather than inherited habit.

Repair Costs, AppleCare+, and the New Risk-Return Calculation

When evaluating a film‑less strategy in 2026, the real question is no longer “Will it scratch?” but “How much financial risk am I actually carrying?” The answer depends less on glass hardness and more on repair pricing and warranty structure.

Display replacement costs for flagship smartphones have climbed sharply due to LTPO 2.0 panels and tandem OLED architectures. For many 2026 premium models, out‑of‑warranty screen repairs range from ¥50,000 to ¥80,000. That headline number understandably fuels anxiety.

However, the risk profile changes dramatically once AppleCare+ or equivalent carrier-backed coverage is factored in. According to Apple’s official support documentation, accidental screen damage under AppleCare+ is serviced for a fixed ¥3,700 fee in Japan.

| Repair Type (iPhone 17 Pro) | With AppleCare+ | Without Coverage (Approx.) |

|---|---|---|

| Front display damage | ¥3,700 | ¥45,000+ |

| Rear glass damage | ¥3,700 | ¥30,000+ |

| Front + rear damage | ¥7,400 | ¥70,000+ |

| Other accidental damage | ¥12,900 | ¥90,000+ |

This gap fundamentally reshapes the cost‑benefit equation. A high‑quality tempered glass protector typically costs several thousand yen and may need replacement multiple times over a device’s lifecycle. Over three years, cumulative spending can approach or exceed the ¥3,700 service fee that restores the display to like‑new condition.

For insured users, the marginal economic advantage of a screen protector becomes surprisingly small. You are effectively choosing between continuous optical compromise and a capped, predictable repair liability.

Carrier programs such as “故障紛失サポート with AppleCare Services” from au or SoftBank’s equivalent offerings further distribute risk across monthly payments. From a financial planning perspective, this converts a potential ¥70,000 shock into a controlled, subscription‑like expense.

Behavioral economics also plays a role. Studies in consumer risk perception consistently show that people overestimate low‑probability, high‑impact losses. In practical terms, users imagine catastrophic breakage scenarios while ignoring the statistical improvement in drop resistance demonstrated by materials like Gorilla Glass Ceramic, which Corning reports can survive repeated one‑meter drops onto asphalt.

The new risk‑return calculation in 2026 is not about preventing every scratch, but about optimizing experience under capped downside risk.

For users without coverage, the equation reverses. A single accident can equal the cost of a mid‑range smartphone. In that context, even a modest reduction in break probability may justify a protector as a risk hedge.

Ultimately, the rational choice depends on three variables: insurance status, personal drop frequency, and tolerance for temporary cosmetic imperfection. Once those are quantified, the decision becomes less emotional and more actuarial—closer to portfolio management than superstition.

In 2026, durability has improved, repair fees are structured, and warranty ecosystems are mature. The question is no longer whether you can afford to go without a film, but whether the experiential upside outweighs a clearly defined, numerically limited downside.

Case Design, Raised Lips, and Alternative Protection Strategies

When going filmless in 2026, case design becomes more critical than ever. Modern smartphones are engineered with subtle structural safeguards, and the most important of these is the raised lip around the display. This seemingly minor detail fundamentally changes real-world scratch dynamics.

According to repair specialists such as iCracked, many recent devices are designed so that the display glass does not directly touch flat surfaces when placed face down. The clearance is often around 0.5 mm. While that number sounds negligible, it is mechanically decisive because friction and micro-abrasion require direct contact.

A properly designed raised lip effectively eliminates planar scratch risk on desks, tables, and countertops. This shifts the protection strategy from covering the glass to controlling how and where it makes contact.

| Design Element | Function | Practical Impact |

|---|---|---|

| Raised lip (≈0.5 mm) | Keeps glass suspended above flat surfaces | Prevents micro-scratches during face-down placement |

| Reinforced corner structure | Absorbs impact energy | Reduces crack initiation on drops |

| Textured or rubberized frame | Improves grip stability | Lowers accidental drop probability |

Importantly, not all cases are equal. Ultra-thin aesthetic cases may sit flush with the screen, nullifying the protective benefit. In contrast, performance-oriented cases deliberately protrude slightly beyond the display plane. For users prioritizing optical purity, this mechanical offset is often a smarter trade-off than adding another reflective layer on top of advanced AR coatings.

Grip ergonomics also play a larger role than many assume. ITmedia reader surveys show that a significant portion of users choose cases primarily for holdability rather than impact resistance. Larger 2026-era smartphones, especially those with heavy camera modules, shift weight upward. A case that stabilizes this center of gravity directly reduces drop frequency, which statistically matters more than marginal surface hardness differences.

Beyond physical cases, alternative strategies are gaining traction. Liquid glass coatings based on silicon dioxide fill microscopic surface irregularities, improving smoothness and finger glide. They add virtually no thickness and preserve anti-reflective performance. However, as industry guidance consistently notes, these coatings do not provide meaningful resistance to point impacts. They are surface conditioners, not structural shields.

Maintenance is another overlooked layer of protection. Apple’s official cleaning guidance emphasizes using only lint-free soft cloths. Harsh chemicals and abrasive materials accelerate the wear of the oleophobic layer. Once that layer degrades, friction increases, fingerprints adhere more strongly, and cleaning becomes more aggressive—ironically increasing micro-abrasion risk.

In practical terms, a balanced filmless strategy in 2026 often looks like this: a case with a measurable raised lip, disciplined pocket management to avoid quartz-rich debris, periodic gentle cleaning, and optional reapplication of oleophobic restorers. This approach preserves display optics while mitigating realistic daily hazards.

The paradigm is no longer “glass versus protector,” but “system design versus careless contact.” With modern ceramic-infused glass and intelligent case geometry, protection becomes architectural rather than additive.

Liquid Coatings and Oleophobic Layer Maintenance: Benefits and Limits

Liquid nano-coatings and the factory-applied oleophobic layer have become central topics in the film‑less era. Instead of adding a physical sheet, users now reinforce the existing glass surface at a microscopic level. This approach prioritizes touch fidelity and optical purity while attempting to preserve day‑to‑day usability.

Most commercial liquid coatings are primarily silica (SiO₂) based. After application, they fill microscopic surface irregularities and cure into an ultra‑thin layer that is invisible to the eye. Because the thickness is measured in microns, they do not interfere with advanced anti‑reflective structures optimized for air contact.

According to maintenance guidance published by manufacturers and coating specialists, these treatments improve finger glide and reduce fingerprint adhesion by increasing surface hydrophobicity and oleophobicity. Users often report a noticeable reduction in drag during fast swipes or gaming sessions, particularly on large LTPO OLED panels.

However, the limits are equally clear. Unlike tempered glass protectors, liquid coatings add virtually no structural thickness. They cannot absorb point impacts or distribute shock energy. In drop scenarios, the underlying glass—whether Gorilla Glass Ceramic or Ceramic Shield 2—remains solely responsible for crack resistance.

| Aspect | Liquid Coating | Tempered Glass Protector |

|---|---|---|

| Thickness | Micron-level | ~0.3–0.5 mm |

| Impact Protection | Minimal | Moderate (sacrificial layer) |

| Optical Impact | Negligible | May increase reflectance |

| Removability | Non-removable | Removable |

The factory oleophobic coating deserves special attention. Smartphone makers apply an extremely thin fluoropolymer-based layer to repel oils and simplify cleaning. Apple’s official care documentation emphasizes that this coating naturally wears down over time and can be degraded by abrasive cleaners or frequent alcohol exposure.

Using lint-free soft cloths is the safest maintenance method. Repeated use of household detergents or strong solvents accelerates deterioration, leading to increased fingerprint visibility and reduced smoothness. Once worn, the tactile difference is immediately noticeable, especially for users accustomed to bare-glass precision.

A growing 2026 trend is at-home “oleophobic refresh” solutions. These products temporarily restore water and oil repellency, partially compensating for natural wear. While they can improve feel and smudge resistance, they do not fully replicate the durability of factory-applied treatments baked under controlled conditions.

In practical terms, liquid coatings and oleophobic maintenance strategies are best viewed as surface optimization tools rather than protective armor. They preserve the premium tactile and visual characteristics of modern anti-reflective glass, aligning perfectly with a film‑less philosophy. Yet they require informed care habits and realistic expectations about what they can—and cannot—protect against.

The Future of Self-Healing Glass and Post-Protector Materials Innovation

Material science is now moving beyond “stronger glass” toward something far more radical: glass and surface layers that can heal themselves. As display durability reaches military-grade benchmarks, the next competitive frontier is not resistance, but recovery.

According to a press release distributed via Kyodo News PR Wire, researchers at Gifu University have developed an elastomer capable of self-repair in roughly 15 minutes at room temperature. The material incorporates fluorinated components into a highly adhesive polymer network, enabling damaged molecular bonds to reconnect autonomously.

This marks a conceptual shift from impact prevention to damage reversibility. Instead of building ever-harder surfaces, engineers are exploring dynamic materials that respond to stress.

| Material Concept | Repair Trigger | Repair Time |

|---|---|---|

| Fluorinated Self-Healing Elastomer | Molecular re-bonding at room temperature | Approx. 15 minutes |

| Conventional Hardened Glass | No self-repair | Not applicable |

While current smartphone displays still rely on ultra-hardened glass-ceramic composites, integration of thin elastomeric top layers is being actively discussed in materials research circles. The idea is not to replace structural glass, but to add a micro-scale adaptive layer that absorbs and erases superficial scratches.

In practical terms, this could eliminate the most common resale-degrading damage: hairline abrasions caused by quartz particles in dust. Even today’s Mohs level 7–8 resistant glass can accumulate micro-scratches under extreme friction. A self-healing topcoat would make those scratches temporary rather than permanent.

The economic implication is profound. If surface blemishes naturally disappear, the logic of disposable screen protectors weakens dramatically. Consumers would no longer be paying for sacrificial layers, but investing in regenerative surfaces.

Another promising direction involves advanced elastomer hybrids that combine elasticity with optical transparency. Historically, soft polymers compromised clarity and increased haze. However, improvements in refractive index matching and nano-scale dispersion techniques are narrowing that gap, enabling flexible materials to maintain flagship-level display sharpness.

Researchers are also exploring stress-distribution architectures inspired by aerospace composites. Instead of a monolithic sheet, future displays may consist of multi-layered systems where each layer performs a distinct function: structural rigidity, impact absorption, scratch healing, and anti-reflection control.

Importantly, these innovations do not signal the immediate disappearance of glass as we know it. Structural fracture resistance remains critical, and brittle failure under high-energy impact still requires ceramic reinforcement. However, combining glass-ceramic substrates with self-healing polymer skins could create hybrid displays that address both catastrophic cracks and everyday wear.

For gadget enthusiasts, this means the conversation is shifting from “Should I apply a protector?” to “What material stack is my device using?” In the near future, spec sheets may list healing time, molecular bonding efficiency, or elastic recovery rates alongside brightness and refresh rate.

When surfaces begin repairing themselves within minutes, protection becomes embedded rather than attached. At that point, the screen protector will no longer be an accessory choice, but a historical footnote in the evolution of mobile materials.

参考文献

- XenoSpectrum:Corning Announces Gorilla Glass Ceramic

- ITmedia Mobile:スマホの保護フィルム/ガラスを“あえて貼らない”理由は?:読者アンケート結果発表

- ITmedia Mobile:スマホに「ケース」「保護フィルム」を使う/使わない理由:読者アンケート結果発表

- Kobonemi:iPhone 17、標準的な画面保護フィルムは逆効果に 反射率テストから …

- Apple:AppleCare+ – Apple(日本)

- イオシス買取:査定基準について スマホ、携帯、iPhone買取なら【イオシス買取】

- 共同通信PRワイヤー:15分程度で自己修復するエラストマーを実現 | 岐阜大学のプレスリリース