Have you ever looked at the inner display of a foldable phone and wondered whether it would feel better without the factory-installed screen protector?

For many gadget enthusiasts, especially those who value smooth touch response and pristine visuals, the idea is tempting. However, with the Galaxy Z Fold 7, this seemingly simple decision can lead to irreversible damage, unexpected repair costs, and serious warranty issues.

This article carefully explains why the main display protection system of the Galaxy Z Fold 7 is fundamentally different from that of conventional smartphones. By understanding the engineering behind Ultra-Thin Glass, the redesigned hinge mechanism, and the role of the protective film as a structural component, you will clearly see the real risks involved. Reading this article will help you protect your investment, avoid common user mistakes, and use your foldable device with confidence and peace of mind.

- The Evolution of Foldable Phones and the New Meaning of Screen Protection

- Inside the Galaxy Z Fold 7 Display Architecture

- How Ultra-Thin Glass Balances Strength and Flexibility

- The Role of the Armor FlexHinge in Display Stress Management

- Why the Inner Screen Protector Is a Structural Component

- Physical Failure Risks Caused by Removing the Protective Film

- Chemical Degradation and Delayed OLED Failures

- Warranty Limitations and Real-World Repair Costs

- Third-Party Screen Protectors: Promises and Hidden Dangers

- Recommended Actions When the Inner Screen Protector Peels or Degrades

- 参考文献

The Evolution of Foldable Phones and the New Meaning of Screen Protection

Foldable smartphones have redefined what users expect from mobile displays, and screen protection has quietly shifted from an optional accessory to a core structural concept. Early foldables were often judged by visible creases or durability concerns, but recent generations show that protection is now inseparable from performance and longevity. **In modern foldables, the screen protector is no longer a cosmetic layer but a functional component of the display system**.

This shift is most evident in devices like Samsung’s Galaxy Z Fold series, which has driven the industry for nearly a decade. According to Samsung Electronics’ own engineering disclosures, extreme thinness and flexibility require a layered approach where glass, polymers, and metal supports work together. The result is a display that bends hundreds of thousands of times, but only when each layer plays its assigned role.

| Era | Screen Protection Concept | User Perception |

|---|---|---|

| Bar-type smartphones | Removable glass or film | Optional accessory |

| Early foldables | Basic polymer layers | Necessary but fragile |

| Latest foldables | Structural protective film | Integral to durability |

At the heart of this evolution is Ultra-Thin Glass, or UTG. Samsung Display reports that UTG has been refined to balance hardness and flexibility, yet it remains fundamentally different from traditional Gorilla Glass. Academic research on flexible OLED stacks shows that UTG alone cannot safely absorb point pressure, making an elastic top layer essential for stress distribution.

Industry repair specialists and materials scientists consistently note that **polymer-based protective films act as sacrificial layers**, absorbing micro-scratches and dispersing localized force before it reaches the brittle glass beneath. Without this buffer, even fingernails or dust particles can initiate microcracks that grow over time through repeated folding.

Hinge design has also influenced the meaning of protection. With water-drop style folding mechanisms now standard, the display undergoes complex three-dimensional deformation. Engineers tune the elasticity of the protective film so it stretches and contracts in harmony with the hinge motion. Using no film, or an ill-matched replacement, disrupts this balance and accelerates material fatigue.

What emerges from this evolution is a new definition of screen protection. It is not about resisting scratches alone, but about preserving mechanical integrity, chemical stability, and long-term reliability. **In foldable phones, protection has become part of the architecture itself**, reflecting a broader industry transition from add-on accessories to integrated engineering solutions.

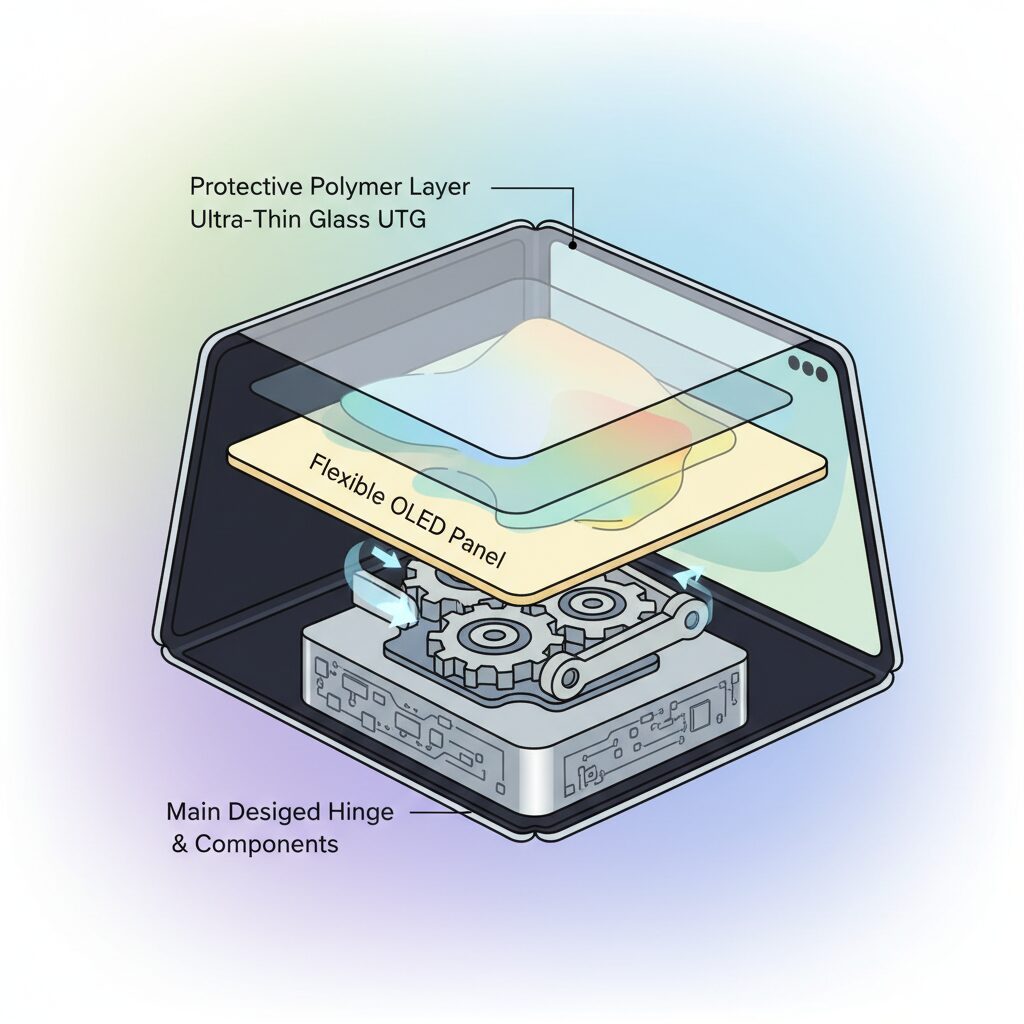

Inside the Galaxy Z Fold 7 Display Architecture

The Galaxy Z Fold 7 main display is not a single panel but a carefully tuned multilayer system designed to balance flexibility, strength, and visual fidelity. Understanding this internal architecture helps clarify why the display behaves differently from conventional smartphones and why each layer plays a structural role rather than a cosmetic one.

At the core of this architecture is Ultra-Thin Glass, or UTG, which has been revised for the Fold 7. According to Samsung Display, the UTG layer is approximately 50% thicker than in the previous generation, a change intended to improve impact resistance while maintaining foldability. This increase may sound counterintuitive, but thicker UTG allows better energy absorption when pressure is applied, similar to concepts used in laminated safety glass.

However, glass physics introduces a trade-off. As materials scientists often point out in flexible OLED research published through institutions such as the U.S. National Institutes of Health, increasing glass thickness improves toughness but reduces tolerance to tight bending radii. To manage this, Samsung relies on a coordinated stack rather than UTG alone.

| Layer | Primary Role | Engineering Benefit |

|---|---|---|

| Protective polymer film | Surface buffer | Distributes point pressure into surface load |

| Ultra-Thin Glass | Structural skin | Improves scratch and impact resistance |

| Titanium backplate | Support layer | Stabilizes bending stress across the panel |

The titanium backplate is particularly important. Samsung’s own engineering briefings describe it as a lightweight but high-strength substrate that spreads mechanical stress across the entire display area. This prevents localized strain from concentrating at the fold line, which is historically the most vulnerable zone in foldable OLEDs.

On the opposite side of the stack, the top protective film serves a less obvious but equally critical function. Rather than acting as a removable accessory, it behaves as a sacrificial layer. Repair specialists cited in technical teardown discussions note that UTG, while glass, is intentionally softer than traditional cover glass. The polymer film absorbs micro-scratches and converts sharp point loads, such as fingernails or stylus tips, into broader surface forces.

The redesigned Armor FlexHinge further complicates the display’s mechanical environment. With a multi-rail structure that guides the panel into a water-drop-shaped curve, the hinge reduces peak stress during folding. At the same time, it requires the display stack to deform in a controlled three-dimensional motion. The elastic modulus of the top film is tuned specifically for this movement, as highlighted by Samsung engineers in public interviews.

Academic studies on flexible OLED reliability emphasize that mismatched elasticity between layers accelerates fatigue failure. In practical terms, the Fold 7 display depends on precise harmony between UTG thickness, polymer elasticity, and backplate stiffness. This architectural balance explains why the display can survive hundreds of thousands of folds, but only when all layers remain intact and work as a unified system.

How Ultra-Thin Glass Balances Strength and Flexibility

Ultra-thin glass plays a paradoxical role in foldable displays, and the Galaxy Z Fold 7 offers a clear example of how strength and flexibility are carefully balanced rather than simply maximized. The UTG used in its main display is not designed to behave like conventional smartphone glass. Instead, it operates as part of a composite system in which controlled fragility is just as important as durability.

Samsung Display increased the thickness of the UTG in the Fold 7 by roughly 50 percent compared with the previous generation, a change confirmed in official engineering briefings. At first glance, thicker glass suggests better durability, and laboratory testing supports this assumption. According to Samsung Display, the panel passed internal durability tests exceeding 500,000 folds under controlled conditions. However, thicker glass also increases bending stiffness, which directly conflicts with the need for smooth, repeatable folding.

From a materials science perspective, glass fails when tensile stress exceeds its fracture threshold. During folding, the outer surface of UTG experiences tension while the inner surface is compressed. To prevent crack initiation, the Fold 7 uses a carefully tuned neutral plane, positioning the UTG within the display stack so that tensile stress is minimized during bending. Academic studies on thin glass laminates, including research published via NIH-backed OLED reliability reviews, emphasize that stress redistribution across layers is more effective than relying on glass strength alone.

| Design Factor | Role in Strength | Role in Flexibility |

|---|---|---|

| UTG Thickness Increase | Improves impact resistance and crack tolerance | Raises bending stiffness, requiring stress control |

| Polymer Top Film | Distributes point loads into surface loads | Allows elastic deformation during folding |

| Titanium Back Plate | Stabilizes the stack against external shock | Maintains consistent bending geometry |

The polymer protective film on top of the UTG is especially critical. While often mistaken for a removable accessory, it functions as a mechanical buffer. Repair specialists such as eziPhoneRepair have noted that UTG hardness is intentionally lower than Gorilla Glass to allow bending, which makes it more vulnerable to point loads. The polymer layer absorbs localized pressure from fingernails or the S Pen and spreads it laterally, reducing peak stress that would otherwise propagate microcracks.

Equally important is the interaction with the Armor FlexHinge. Its water-drop folding geometry increases the bending radius, reducing strain on the glass. Yet this geometry introduces complex three-dimensional deformation. The surface layers must stretch and relax repeatedly, and only materials with precisely matched elastic moduli can survive this cycle. Research on flexible OLED encapsulation shows that mismatched stiffness accelerates fatigue failure, even if individual materials are strong in isolation.

In practical terms, the Fold 7’s UTG demonstrates that strength and flexibility are not opposing goals but interdependent variables. Strength is achieved by managing where and how stress appears, while flexibility is preserved by allowing controlled, elastic sacrifice in outer layers. This balance explains why removing or altering any layer disrupts the system, even if the glass itself appears thicker and stronger than before.

The Role of the Armor FlexHinge in Display Stress Management

The Armor FlexHinge plays a central role in how the Galaxy Z Fold 7 manages mechanical stress on its main display, and its importance goes far beyond simply enabling the fold. From an engineering perspective, this hinge is designed as an active stress-control system rather than a passive joint, and this distinction is critical for understanding long-term display reliability.

Samsung Electronics explains that the third-generation Armor FlexHinge is approximately 27% thinner and 43% lighter than the previous design, while still supporting a more complex multi-rail structure. This architecture allows the display to follow a controlled, water-drop-like folding path, which increases the effective bending radius at the crease. **By enlarging the bending radius, peak tensile and compressive stresses within the Ultra-Thin Glass are significantly reduced**, especially during repeated open-and-close cycles.

| Design Element | Mechanical Function | Impact on Display Stress |

|---|---|---|

| Multi-rail hinge structure | Guides panel along a fixed 3D trajectory | Prevents localized strain concentration |

| Water-drop folding geometry | Increases bending radius at the crease | Reduces fatigue in UTG and OLED layers |

| Armor-grade materials | Maintains rigidity with lower mass | Stabilizes motion and suppresses vibration |

What is often overlooked is that the hinge does not work in isolation. According to Samsung Display’s durability disclosures and independent teardown analyses, the hinge, the UTG layer, and the surface protection film are mechanically tuned as a single system. The hinge defines how the panel bends, but the protective polymer layer determines how smoothly stress is redistributed across the surface during that motion. **If this balance is disrupted, even a well-designed hinge cannot fully prevent stress concentration**.

Materials science research on flexible OLEDs, including studies referenced by the U.S. Department of Energy, shows that repeated cyclic bending can accelerate microcrack growth when strain is unevenly distributed. The Armor FlexHinge addresses this risk by ensuring that folding-induced deformation is gradual and spatially spread out. This is especially important at the crease, where previous-generation foldables tended to accumulate mechanical fatigue.

However, the hinge’s effectiveness depends heavily on the elastic compliance of the topmost layers. The factory-installed protective film is engineered to flex in harmony with the hinge motion. When users remove this layer or replace it with a film of different stiffness, the hinge-driven folding path remains the same, but the surface layers respond differently. **This mismatch can shift stress back into the UTG and OLED stack**, undermining the very benefits that the Armor FlexHinge was designed to provide.

From a reliability standpoint, this explains why professional repair technicians frequently associate hinge-area failures with prior film removal. The hinge continues to guide the fold precisely, but without the correct surface elasticity, stress becomes localized rather than absorbed. Over tens of thousands of folds, this can translate into earlier onset of crease whitening, microfractures, or pixel-level damage.

In practical terms, the Armor FlexHinge should be seen as a precision stress-management mechanism that assumes very specific boundary conditions. When those conditions are respected, it enables the Galaxy Z Fold 7 to achieve both extreme thinness and high durability. When they are altered, the hinge cannot compensate alone, and the display bears the cost.

Why the Inner Screen Protector Is a Structural Component

The inner screen protector on the Galaxy Z Fold 7 is often misunderstood as a removable accessory, but from an engineering standpoint it functions as a structural component of the display stack. Samsung Display treats this polymer layer as part of the load-bearing system that allows ultra-thin glass to bend repeatedly without catastrophic failure. According to Samsung’s official engineering briefings, the protector is designed together with UTG, OLED layers, and the hinge to behave as a single mechanical unit.

The key role of the inner protector is stress redistribution. Ultra-thin glass becomes stronger with added thickness, but also less forgiving under point pressure. The protector converts localized force from a fingertip, stylus, or dust particle into surface-wide stress, lowering peak strain on the UTG. This principle mirrors laminated safety glass used in architecture, where polymer interlayers prevent crack propagation even after micro-fractures appear.

| Layer | Primary Function | Failure Risk Without Protector |

|---|---|---|

| Polymer protector | Stress diffusion and surface compliance | Point-load induced cracks |

| UTG | Bending transparency and rigidity balance | Brittle fracture, crease damage |

| OLED stack | Image generation | Delamination, dead pixels |

Academic OLED reliability studies published via the U.S. National Institutes of Health explain that even microscopic surface cracks can accelerate organic layer degradation once mechanical protection is compromised. In a foldable device, this effect is amplified because bending cycles repeatedly reopen those micro-cracks. The inner protector acts as a controlled sacrificial layer, absorbing abrasion and elastic deformation before stress reaches the glass or encapsulation films.

Removing the protector therefore alters the mechanical equilibrium of the entire display. Independent teardown analyses and repair specialists consistently report that devices used without the factory protector show higher rates of UTG cracking and OLED delamination, even when no obvious external damage is present. In structural terms, the protector is not cosmetic at all; it is a tuned interface that keeps the Fold 7’s display stable over hundreds of thousands of folds.

Physical Failure Risks Caused by Removing the Protective Film

Removing the factory-installed protective film from the Galaxy Z Fold 7 directly increases the risk of irreversible physical failure. **Unlike conventional smartphones, this film is not a cosmetic accessory but an integrated mechanical component** designed to stabilize the ultra-thin display stack during daily folding and touch interactions.

Samsung Display’s engineering disclosures explain that the Fold 7 relies on a thicker UTG layer to improve impact resistance, but thicker glass also becomes more sensitive to localized stress. The protective film acts as a stress-diffusion interface, converting sharp point loads into broader surface pressure before they reach the glass.

When the film is removed, this buffering mechanism disappears entirely, exposing the UTG and OLED layers to concentrated mechanical forces that they were never designed to tolerate on their own.

| With Protective Film | Without Protective Film | Physical Consequence |

|---|---|---|

| Point load is dispersed | Point load is concentrated | Micro-cracks form in UTG |

| Surface absorbs minor scratches | Direct contact with UTG | Permanent surface damage |

| Elastic deformation during folding | Rigid stress transfer | Accelerated fatigue at the crease |

A critical but often overlooked risk occurs during the act of removal itself. The adhesive used on the Fold 7’s film is intentionally strong to prevent lifting during hundreds of thousands of hinge cycles. **Peeling the film introduces vertical tensile stress**, which OLED panels are structurally weak against.

Display engineers and independent repair specialists report that this stress can exceed interlayer bonding strength, causing internal delamination. User reports describing audible cracking sounds or immediate black lines across the crease align with known failure modes of layered OLED assemblies.

Even if removal appears successful, the display enters a fragile state. Repair professionals note that fingernails, stylus tips, or microscopic debris trapped during folding can apply enough pressure to initiate UTG fractures. These fractures may be invisible at first, yet they compromise the structural continuity of the panel.

**Repeated folding then turns minor defects into catastrophic failures.** Stress concentrates around the crease, where material fatigue is already highest, allowing micro-cracks to propagate across the display matrix.

Research on OLED durability published in peer-reviewed materials science journals shows that mechanical micro-damage often precedes electrical failure. Once the UTG is compromised, underlying OLED pixels can collapse under minimal additional force, manifesting as black spots or dead lines.

What makes this risk particularly severe is its delayed nature. Users frequently report that the display functions normally for days or weeks after film removal, only to fail suddenly. This behavior is consistent with fatigue-driven fracture growth rather than immediate impact damage.

Authoritative teardown analyses further confirm that the Fold 7’s display layers are engineered as a unified system. Altering one layer disrupts load balancing across the hinge motion path, increasing uneven stress distribution with every open-and-close cycle.

In practical terms, the physical risks are not theoretical. Independent service centers consistently categorize film-removed displays as high-risk units, noting a significantly higher incidence of UTG cracking and OLED collapse compared to untouched devices.

For users attracted by the idea of a cleaner look or smoother touch, the trade-off is stark. **The moment the film is removed, the Fold 7 transitions from a controlled engineering system into a mechanically exposed structure**, where normal daily interactions can trigger permanent hardware failure.

Chemical Degradation and Delayed OLED Failures

One of the most misunderstood risks of removing the main display’s protective film lies not in immediate breakage, but in chemical degradation that progresses silently over time. In foldable OLED panels such as those used in the Galaxy Z Fold 7, chemical stability is as critical as mechanical strength, and the protective film plays a frontline role in that defense.

OLED pixels are composed of organic emissive materials that are inherently vulnerable to oxygen and moisture. According to reviews published in peer‑reviewed OLED reliability research, even trace amounts of H2O or O2 can trigger irreversible reactions that suppress light emission. These reactions do not occur all at once. Instead, they accumulate gradually, which is why many failures appear days or weeks after the initial damage.

The protective film contributes to a multi‑layer barrier system that works alongside thin‑film encapsulation. While the encapsulation layer is engineered to block diffusion, it is extremely thin and susceptible to micro‑cracks. Once the surface film is removed, the chemical barrier is effectively reduced to a single fragile line of defense, making long‑term stability far more dependent on perfect handling conditions.

| Stage | Chemical Process | Visible Symptom |

|---|---|---|

| Initial use | Microscopic cracks allow moisture ingress | No visible change |

| Early degradation | Cathode oxidation begins | Faint dark pixels |

| Advanced failure | Organic layer decomposition spreads | Expanding dark spots or lines |

Studies cited by materials scientists and energy research institutions explain that water molecules migrate through defects via diffusion and capillary action. Under an electric field, these molecules are driven toward the cathode interface, where oxidation accelerates. This mechanism explains why dark spots often grow even when the phone is no longer exposed to obvious stress.

User reports and teardown analyses reinforce this model. Devices that initially appeared functional after film removal later developed clustered black spots along the crease area, a region already prone to higher strain and micro‑fracturing. Because the chemical reaction continues as long as moisture is present, the affected area rarely remains static and instead expands over time.

What makes delayed OLED failure particularly severe is its irreversibility. Unlike surface scratches, chemically degraded pixels cannot be repaired or reactivated. Display engineers consistently note that once oxidation has progressed beyond a critical threshold, the only remedy is full panel replacement.

In practical terms, removing that shield trades a short‑term improvement in tactile feel for a long‑term chemical countdown. The danger is not dramatic or immediate, which is why it is often underestimated, but the outcome is among the most final failures an OLED display can suffer.

Warranty Limitations and Real-World Repair Costs

When discussing warranty coverage for the Galaxy Z Fold 7, many users assume that protection works the same way as on conventional smartphones, but this assumption often leads to costly misunderstandings. **Samsung treats the inner display protection system as part of the core structure**, not as a removable accessory, and this distinction has a direct impact on how warranty claims are evaluated in real-world repair scenarios.

According to Samsung’s official support documentation in the United States, damage to the main screen after the factory-installed protective film has been removed may be excluded from warranty coverage. This wording is carefully chosen. Removing the film is not always listed as an automatic warranty void, but once damage occurs, the absence of the film significantly weakens the user’s position. Authorized service providers are instructed to assess whether the failure could be linked to non-standard use, and film removal often becomes a decisive factor.

This assessment process becomes clearer when looking at how repairs are handled on the ground. Reports from authorized partners such as Asurion and Samsung-certified repair centers show a consistent pattern. Technicians first check whether the inner display still has the factory film applied, then look for micro-scratches, pressure marks, or hinge-area wear. If the film is missing and any display defect is present, the probability of a CID judgment increases sharply, regardless of how carefully the device was used.

| Condition at Service Intake | Typical Warranty Outcome | User Cost Impact |

|---|---|---|

| Film intact, no external damage | Warranty repair likely | Minimal or none |

| Film removed, display defect present | CID judgment common | High out-of-pocket cost |

| Film lifting, officially replaced | Warranty preserved | Often free or low fee |

From an economic standpoint, the consequences are severe. Industry estimates and user reports indicate that an out-of-warranty inner display replacement for the Galaxy Z Fold 7 can approach half the retail price of the device. In several documented cases shared by users, repair quotes in the range of several hundred US dollars were issued after warranty denial, even when the phone was less than a year old.

Samsung Care+ and similar protection plans do mitigate this risk, but they do not eliminate it entirely. These programs typically involve a fixed deductible and annual claim limits. **Using up a claim due to film-related damage reduces future protection for more serious incidents**, such as drops or hinge failures, which introduces an additional hidden cost.

Experts in OLED reliability, including researchers cited in publications indexed by the U.S. National Institutes of Health, emphasize that once internal layers are compromised, repair options are effectively limited to full module replacement. This aligns with Samsung’s repair policy, which does not support partial refurbishment of the foldable inner display. As a result, even minor damage escalates into a major financial event.

For users evaluating whether to remove or replace the inner film themselves, the warranty landscape alone provides a strong deterrent. The short-term tactile or visual benefits are outweighed by the long-term financial exposure. **In real-world ownership, warranty limitations turn the inner display film into one of the most economically critical components of the Galaxy Z Fold 7**, despite its seemingly modest appearance.

Third-Party Screen Protectors: Promises and Hidden Dangers

Third-party screen protectors for foldable devices often promise a better touch feel, reduced glare, or superior fingerprint resistance. On paper, these claims sound appealing, especially to gadget enthusiasts who value customization. However, with the Galaxy Z Fold 7, these promises frequently mask risks that are not obvious at the time of purchase.

The core issue lies in material mismatch. Samsung’s factory-applied film is engineered as part of the display system, tuned to the elasticity of UTG and the deformation path of the Armor FlexHinge. **Many third-party films optimize for hardness or smoothness, not for controlled stress distribution during repeated folding.** According to analyses from professional repair technicians and teardown specialists, even small deviations in elastic modulus can amplify stress at the crease, accelerating fatigue in the glass and OLED layers.

| Protector Type | Main Advantage | Hidden Risk |

|---|---|---|

| TPU-based | High flexibility | Surface distortion, uneven pressure absorption |

| PET-based | Clear image, smooth feel | Poor fold compliance, edge lifting |

| Hybrid or glass-like | Scratch resistance | Cracking under repeated folding |

Another underestimated danger is installation. Unlike slab phones, the Fold 7 requires near-micron-level alignment. Industry sources, including materials engineers cited in OLED reliability studies published via NIH-backed journals, note that uneven adhesive tension can introduce localized peel forces. **When users reapply or remove a misaligned protector, the adhesive force alone can trigger internal delamination**, a failure mode repeatedly reported by authorized service partners.

Community data reinforces this technical concern. User reports aggregated from large enthusiast forums show a pattern: third-party films often perform well for days or weeks, then begin lifting at the hinge. Once airborne edges trap dust, every fold acts like controlled abrasion. Researchers studying OLED dark-spot formation explain that microcracks created this way allow moisture ingress, leading to irreversible pixel death over time.

Perhaps the most overlooked consequence is economic rather than technical. **Service centers frequently treat damage discovered beneath a non-original protector as customer-induced**, regardless of intent. From a warranty perspective, the protector itself becomes circumstantial evidence. What began as a minor upgrade can therefore escalate into a full display replacement at near four-figure cost.

In short, third-party screen protectors for the Galaxy Z Fold 7 do deliver short-term tactile improvements, but they do so by stepping outside the device’s finely balanced mechanical design. For a foldable display operating at the limits of material science, that trade-off is far more dangerous than it appears.

Recommended Actions When the Inner Screen Protector Peels or Degrades

When the inner screen protector of the Galaxy Z Fold 7 begins to peel, bubble, or visibly degrade, the most important principle is to avoid taking immediate action driven by discomfort or aesthetics. **Any attempt to press it down, trim it, or peel it off manually introduces mechanical stress that the display stack is not designed to tolerate.** Samsung Display’s own engineering disclosures emphasize that the protector functions as a load-distribution and strain-buffer layer rather than a disposable accessory.

The first recommended action is careful observation. Mild bubbling near the hinge area can sometimes stabilize temporarily, as reported by user case aggregations in Galaxy Fold communities and acknowledged in Samsung support guidance. During this phase, it is advisable to reduce folding frequency and keep the device away from humidity and dust, as moisture and particulate intrusion accelerate both adhesive failure and OLED degradation.

| Protector Condition | User Action | Technical Rationale |

|---|---|---|

| Slight lift or small bubbles | Monitor and limit folding | Adhesive stress may re-equalize without inducing shear force |

| Peeling near the crease | Contact official service promptly | Debris ingress can create point loads on UTG |

| Tears or surface damage | Request professional replacement | Loss of sacrificial layer increases fracture risk |

If peeling progresses or reaches the crease, professional intervention becomes critical. **Authoritative repair analyses and OLED reliability studies published via NIH-backed research indicate that even micro-gaps allow moisture diffusion that leads to delayed dark-spot formation.** This means waiting too long can convert a simple film replacement into a full panel failure.

At this stage, the optimal action is to use Samsung-authorized service channels. These centers employ alignment jigs and controlled removal techniques that minimize vertical tensile stress, the primary cause of OLED delamination. Community-documented failures show that self-removal, even when done slowly, often results in instantaneous black lines or weeks-later pixel death, underscoring the hidden nature of the damage.

Continuing to use the device without a properly bonded inner protector is equivalent to operating exposed ultra-thin glass under repeated flexion. From an engineering and warranty perspective, this dramatically increases both failure probability and the likelihood of customer-induced damage classification.

In short, when degradation appears, restraint is the most effective response. Observing early, escalating quickly to official replacement when symptoms worsen, and resisting all DIY fixes align not only with Samsung’s official precautions but also with the consensus of display engineers and repair specialists who work directly with foldable OLED failures.

参考文献

- Samsung Newsroom:The Breakthroughs Powering Samsung’s Thinnest, Most Refined Foldables

- Samsung Display:Foldable OLED Panel Proves Exceptional Durability with 500,000-Fold Test

- NIH / PubMed Central:Unraveling Degradation Processes and Strategies for Enhancing Reliability in Organic Light-Emitting Diodes

- Reddit:PSA: The Screen Protector Can and WILL Break Your Inner Display If Left Loose

- Samsung Support:Screen Protector Replacement for Samsung Galaxy Z Series Promotion Terms

- eziPhoneRepair:Galaxy Flip & Fold Screen Damage Explained | Black Spots, Pressure Marks, and Repair Tips