Foldable smartphones have always promised the future, yet durability has remained the biggest question mark for many gadget enthusiasts.

With the release of the Galaxy Z Fold 7, Samsung challenges long‑standing assumptions by combining an ultra‑thin 8.9 mm body with reinforced materials and a redesigned hinge.

If you have ever wondered whether modern foldables are finally tough enough for everyday life, this article will give you clear, evidence‑based answers.

In this guide, you will explore how Samsung’s engineering decisions affect real‑world durability, from frame alloys and hinge mechanics to water and dust resistance.

You will also learn why the IP48 rating has sparked controversy, how it compares with IP68 rivals, and what that difference actually means outside the spec sheet.

By understanding independent stress tests, teardown analyses, and material science insights, you will be better equipped to judge whether the Galaxy Z Fold 7 fits your usage style and risk tolerance.

This article is designed to help you make a confident, informed decision before investing in one of the most ambitious foldable devices ever released.

- Why Durability Defines the Future of Foldable Smartphones

- Ultra‑Thin Design vs Structural Strength: Inside the Z Fold 7 Frame

- Armor Flex Hinge Explained: Mechanical Innovation and Its Limits

- IP48 Decoded: What Dust and Water Resistance Really Mean

- IP48 vs IP68: How Galaxy Z Fold 7 Compares to Pixel Fold Rivals

- Material Science Spotlight: Gorilla Glass Victus Ceramic 2

- The Inner Display Challenge: UTG, Crease Stress, and Scratch Risk

- What Stress Tests Reveal: JerryRigEverything and Real‑World Abuse

- Teardown Insights: Repairability, Adhesives, and Long‑Term Wear

- Who the Galaxy Z Fold 7 Is Built For and Who Should Think Twice

- 参考文献

Why Durability Defines the Future of Foldable Smartphones

Durability is no longer a secondary concern for foldable smartphones; it is the factor that will ultimately decide whether this category becomes mainstream or remains niche. Early foldables impressed users with novel form factors, but concerns about fragility, hinge failure, and screen damage consistently slowed adoption. As consumer expectations mature, a foldable phone is now expected to survive years of daily use, not just demonstrate technical possibility.

Industry analysts and materials scientists increasingly point out that durability directly correlates with trust. According to Corning’s materials research, users subconsciously equate physical robustness with overall product quality, especially in premium devices. This insight explains why recent foldables emphasize structural integrity as strongly as display size or processor performance.

The challenge is unique to foldables because durability is dynamic, not static. A conventional smartphone must resist drops and scratches, while a foldable must also endure repeated mechanical stress from opening and closing. Research shared by Samsung Electronics indicates that hinge fatigue, frame torsion, and micro-crack propagation in ultra-thin glass are the primary long-term failure modes, not catastrophic drops.

From an engineering perspective, this shifts the design priority from pure thinness to balanced resilience. A thinner device that fails prematurely undermines the entire value proposition of portability. Conversely, a slightly thicker but structurally stable foldable reassures users that the device can function reliably for multiple upgrade cycles.

| Durability Factor | Why It Matters | User Impact |

|---|---|---|

| Hinge longevity | Repeated mechanical motion causes wear | Confidence in daily open-close use |

| Frame rigidity | Prevents torsion when unfolded | Reduced risk of internal damage |

| Material resilience | Controls crack and scratch propagation | Long-term visual and functional quality |

Independent stress tests by well-known durability reviewers have reinforced this shift. They consistently show that modern foldables rarely fail immediately; instead, gradual degradation determines lifespan. This reality means that durability defines not only survival, but perceived value over time.

In this context, durability becomes a strategic differentiator. As foldable prices remain firmly in the premium tier, users expect them to outlast standard smartphones, not merely match them. Devices that convincingly address long-term mechanical and material fatigue will set the benchmark for the future of foldable smartphones.

Ultra‑Thin Design vs Structural Strength: Inside the Z Fold 7 Frame

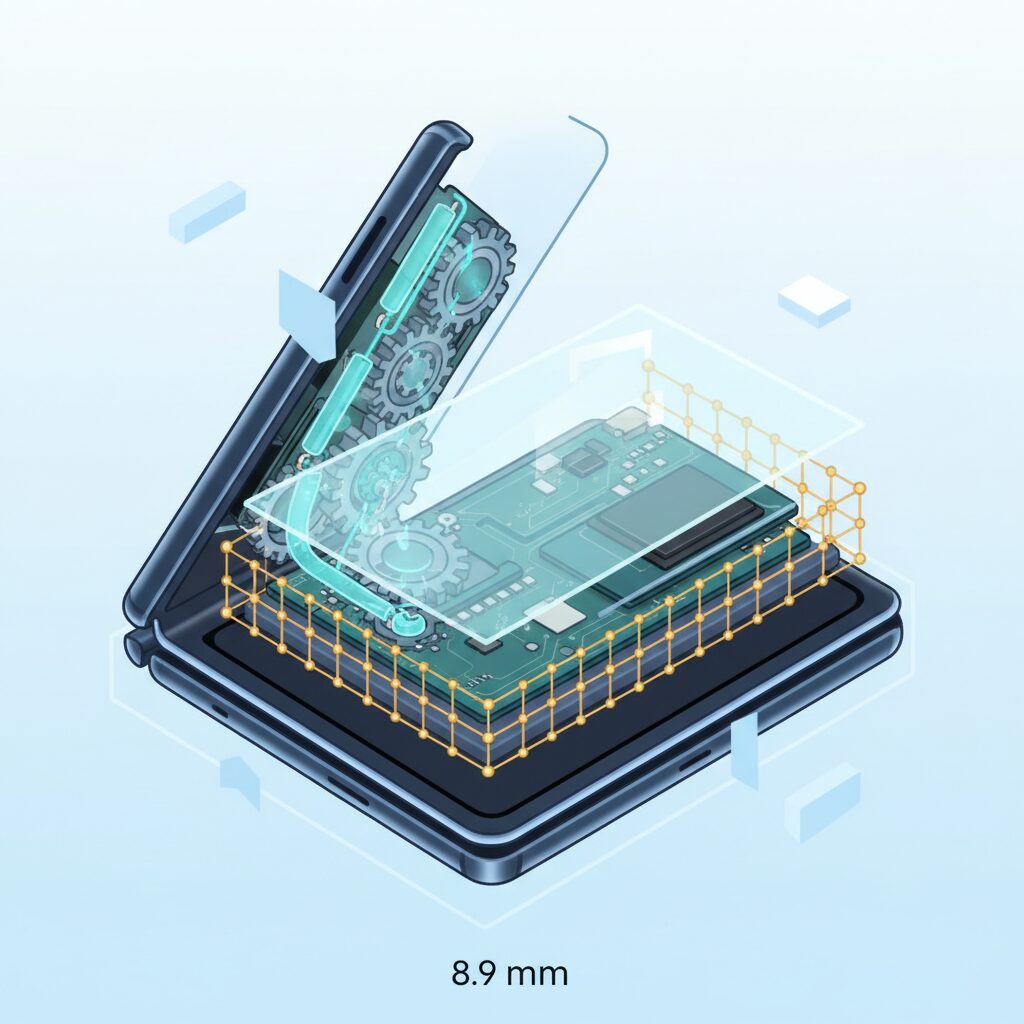

The Galaxy Z Fold 7 pushes ultra‑thin industrial design to an extreme, yet its frame engineering shows that thinness does not automatically mean fragility. When folded, the device measures just 8.9 mm, and when unfolded it reaches an astonishing 4.2 mm. **At this scale, even minor torsional forces can become structural threats**, which is why Samsung’s frame design deserves closer attention.

At the core of the chassis is what Samsung calls Advanced Armor Aluminum. According to Samsung Electronics’ own engineering briefings, this alloy is not simply lighter aluminum, but a reformulated metal designed to raise yield strength without adding mass. Materials science literature published by Corning and referenced by Samsung suggests that micro‑level compositional tuning can significantly improve resistance to bending and permanent deformation, a crucial requirement for a foldable this thin.

What makes this especially relevant is how forces act on a foldable phone. When opened flat, the Z Fold 7 behaves more like a thin tablet than a phone, meaning twisting loads are distributed across a much wider surface. **A weaker frame would flex, transferring stress directly to the hinge and the inner display**. Independent durability tests reported by JerryRigEverything show that the Z Fold 7 resists this flexing better than previous generations, even under deliberate torsion.

| Frame Element | Material Choice | Engineering Purpose |

|---|---|---|

| Main chassis | Advanced Armor Aluminum | Increase yield strength while minimizing thickness |

| Display support plate | Titanium layer | Distribute impact energy and prevent localized bending |

A particularly interesting decision is the use of a titanium plate beneath the main display. Titanium’s high strength‑to‑weight ratio is well documented in aerospace research, and Samsung appears to be applying the same principle here. Compared with carbon fiber or stainless steel used in earlier models, titanium allows the frame to stay thin while acting as a rigid backbone that protects the fragile Ultra‑Thin Glass during drops or uneven pressure.

The hinge integration further highlights the balance between thinness and strength. The redesigned Armor Flex Hinge is significantly slimmer and lighter than before, yet it locks into the reinforced frame at multiple points. iFixit’s teardown analysis notes that these anchor points are essential, because **the frame and hinge now function as a single structural system rather than separate components**. This approach helps explain why the device survives extreme reverse‑bend tests without catastrophic failure.

From an engineering philosophy perspective, the Z Fold 7 frame represents a shift from simply reinforcing weak spots to optimizing load paths throughout the entire body. Academic research on thin‑shell structures shows that distributing stress evenly is more effective than adding bulk at isolated points, and Samsung’s design aligns closely with this principle. The result is a foldable phone that feels almost impossibly slim in hand, yet behaves like a rigid object when subjected to real‑world forces.

Ultimately, **the Z Fold 7 frame proves that ultra‑thin design and structural strength are no longer mutually exclusive**, provided material science and mechanical integration are pushed to their limits. This frame does not eliminate every durability concern inherent to foldables, but it clearly redefines how much strength can be engineered into a device this thin.

Armor Flex Hinge Explained: Mechanical Innovation and Its Limits

The Armor Flex Hinge is the mechanical core that defines how the Galaxy Z Fold 7 feels, moves, and ultimately survives daily use. Samsung positions this hinge not merely as a connector, but as a precision load-distribution system designed to reconcile extreme thinness with structural control.

At its heart, the hinge continues to rely on a gear-based, multi-rail architecture. According to Samsung’s own engineering disclosures, this structure is now approximately 27% thinner and 43% lighter than the previous generation, achieved by reducing the thickness of individual rotating components while maintaining high-strength alloys. This allows the display to fold into a water-drop shape, increasing the bending radius and reducing tensile stress on the Ultra-Thin Glass layer.

This geometry directly improves crease longevity and tactile smoothness during unfolding, a point consistently highlighted by independent teardown analyses from iFixit, which show more uniform stress dispersion across the hinge rails.

| Aspect | Armor Flex Hinge (Z Fold 7) | Cam-Based Hinges (Competitors) |

|---|---|---|

| Core Mechanism | Interlocking gears and sliding rails | Gearless friction cam |

| Flex Mode Stability | High, angle holds firmly | Moderate, angle drift possible |

| Sealing Potential | Limited by mechanical clearance | High, easier full enclosure |

One clear advantage of the gear-based approach is Flex Mode precision. The hinge can lock the display at a wide range of angles with consistent torque, which reviewers such as GSMArena note feels more deliberate and controlled than friction-based alternatives. This mechanical certainty is not accidental; it is the result of physical teeth engagement rather than surface friction alone.

However, this same precision introduces its most serious limitation. Gears cannot operate without clearance. Even at microscopic tolerances, these gaps create pathways that are difficult to seal completely. As explained in analyses cited by Android Central, this is the primary reason the Armor Flex Hinge remains constrained to an IP48 rating instead of full dust resistance.

Samsung partially mitigates this risk with internal nylon sweepers that brush debris away during each fold. Teardown footage shows these components working effectively against lint and fibers, but materials science research indicates that hard mineral particles such as sand can bypass bristles and accumulate within gear tracks.

In practical terms, the Armor Flex Hinge represents a deliberate engineering trade-off. It prioritizes folding feel, angle stability, and minimal thickness over total environmental isolation. For users, this means an exceptional mechanical experience, paired with a responsibility to avoid dust-intensive environments. The innovation is real, but so are its physical limits.

IP48 Decoded: What Dust and Water Resistance Really Mean

When you see an IP48 rating on a premium foldable, it can sound reassuring at first glance, but the reality is more nuanced. IP ratings are defined by IEC 60529, an international standard used across consumer electronics. According to this framework, the two digits describe protection against solid objects and water separately, and understanding that distinction is essential for real-world use.

The “4” in IP48 does not mean dustproof. It simply means the device is protected against solid objects larger than 1.0 mm. Wires or small screws are blocked, but fine particles are not. The “8” indicates resistance to continuous immersion in water, typically up to 1.5 meters for 30 minutes under manufacturer-defined conditions, a level Samsung itself documents in its official support materials.

| IP Digit | What It Covers | Practical Meaning |

|---|---|---|

| 4 | Solid objects | Blocks items ≥1.0 mm, not fine dust or sand |

| 8 | Water | Survives prolonged immersion under test conditions |

This is where expectations often diverge from physics. Geological studies show that common beach sand ranges roughly from 0.1 mm to 2.0 mm in diameter, meaning a significant portion of sand particles are small enough to bypass an IP4 barrier. Independent teardowns analyzed by iFixit and durability tests highlighted by JerryRigEverything have demonstrated how such particles can migrate through hinge gaps over time.

Water resistance and dust resistance behave very differently in daily life. Water exposure is usually brief and uniform, while dust is abrasive, persistent, and mobile. Once fine particles enter a hinge mechanism, repeated folding can push them deeper, where they may concentrate stress against the back of the flexible OLED panel. This failure mode has been documented repeatedly by repair specialists and long-term reviewers.

Samsung’s approach reflects a deliberate trade-off. By maintaining a complex gear-based hinge that prioritizes smooth Flex Mode stability and extreme thinness, microscopic clearances remain unavoidable. As Google’s engineering team explained when discussing IP68 foldables, eliminating gears makes full sealing far easier. IP48, therefore, should be read not as a flaw in testing, but as an honest signal of design priorities.

For users, the takeaway is practical rather than theoretical. The device can confidently survive rain, spills, or an accidental drop into water. At the same time, environments with fine dust or sand demand caution. IP48 protects against water accidents, not against the slow wear of particles smaller than a millimeter. Understanding this distinction helps set expectations and ultimately prevents costly surprises.

IP48 vs IP68: How Galaxy Z Fold 7 Compares to Pixel Fold Rivals

When comparing foldable flagships, the gap between IP48 and IP68 ratings is not a minor spec detail but a reflection of fundamentally different engineering priorities. Galaxy Z Fold 7 remains certified at IP48, while its key rival, the Pixel Fold line, has reached IP68. This difference directly shapes how confidently each device can be used in real-world environments.

IP48 means protection against solid objects larger than 1 mm and strong water resistance, but it does not mean full dustproofing. According to the IEC 60529 standard referenced by Samsung and other manufacturers, particles smaller than 1 mm, including fine sand or dust, may still enter the device. By contrast, IP68 represents complete dust sealing alongside water immersion resistance.

| Model | Dust Protection | Water Resistance |

|---|---|---|

| Galaxy Z Fold 7 | IP4X (no dustproof seal) | IPX8 (1.5 m / 30 min) |

| Pixel Fold rival | IP6X (fully dustproof) | IPX8 equivalent |

This divergence is closely tied to hinge architecture. Samsung continues to rely on a multi-gear hinge designed to deliver a refined Flex Mode experience and an ultra-thin folded profile of 8.9 mm. Engineering analyses cited by Android Central explain that gear-based systems inherently require micro-clearances, which make full dust sealing extremely difficult. Google, on the other hand, adopted a gearless cam-style hinge that can be fully enclosed, enabling IP68 certification.

Independent durability testing adds important nuance. Teardowns and stress tests reported by iFixit and JerryRigEverything show that the Z Fold 7’s internal sweepers can eject lint and larger debris, but fine mineral particles can still migrate inward over time. Pixel Fold devices, benefiting from sealed hinges, show significantly lower risk in sandy or dusty settings.

From a user perspective, the implication is practical rather than theoretical. Z Fold 7 is highly resistant to rain, spills, and accidental immersion, yet it demands caution in environments like beaches or construction sites. Pixel Fold rivals trade extra thickness for peace of mind in such conditions. This contrast clearly illustrates that IP48 versus IP68 is not about numbers alone, but about choosing between slim elegance and maximum environmental resilience.

Material Science Spotlight: Gorilla Glass Victus Ceramic 2

Gorilla Glass Victus Ceramic 2 represents a clear shift in how Samsung approaches exterior durability, and this material choice deserves close attention. Unlike conventional aluminosilicate smartphone glass, this glass-ceramic composite is engineered through controlled crystallization, a process long studied in materials science for applications where crack resistance is critical.

According to Corning’s official product information, the key innovation lies in the formation of nanometer-scale crystals within the glass matrix. These crystals act as physical barriers that interrupt crack propagation when the surface experiences impact stress. This mechanism fundamentally changes how damage spreads, turning catastrophic shattering into localized micro-fractures.

From a mechanical standpoint, this is especially relevant for foldables, which are statistically more likely to be dropped due to their larger footprint and higher center of mass. Independent materials research cited by Corning shows that glass-ceramics can withstand repeated impact on rough surfaces, such as concrete, significantly better than fully amorphous glass.

| Property | Victus 2 | Victus Ceramic 2 |

|---|---|---|

| Internal structure | Amorphous glass | Glass-ceramic with nano-crystals |

| Vickers hardness | Approx. 620 kgf/mm² | Approx. 640–660 kgf/mm² |

| Crack propagation behavior | Linear expansion | Interrupted and dispersed |

The increase in Vickers hardness may appear modest on paper, but in real-world use it translates into improved scratch resistance against everyday abrasives such as sand particles or mineral dust. This is particularly meaningful for a premium device that is often used without a case to showcase its thin profile.

Another often overlooked aspect is density. Victus Ceramic 2 is slightly denser than standard smartphone glass, which contributes to a more solid tactile feel despite reduced thickness. Materials engineers frequently point out that perceived quality is closely tied to vibrational damping, and denser glass-ceramics tend to transmit less high-frequency vibration upon impact.

Corning researchers have also noted that glass-ceramic materials distribute impact energy laterally rather than vertically. For the Galaxy Z Fold 7, this characteristic works in tandem with the reinforced frame, reducing the likelihood that a localized drop transfers destructive force into internal layers.

In the broader industry context, this material choice can be read as Samsung’s direct response to Apple’s Ceramic Shield. While the two are developed independently, both rely on similar principles validated by decades of academic research in crystallized glass systems. The result is not indestructibility, but a meaningful extension of survivability in everyday accidents.

Ultimately, Gorilla Glass Victus Ceramic 2 is less about marketing spectacle and more about incremental, evidence-based improvement. For users who demand both extreme thinness and confidence against drops, this material quietly underpins the Galaxy Z Fold 7’s claim to be one of the most structurally resilient foldables to date.

The Inner Display Challenge: UTG, Crease Stress, and Scratch Risk

The inner display remains the most delicate component of the Galaxy Z Fold 7, and the challenges around UTG, crease stress, and scratch risk have not disappeared despite clear progress. Samsung has increased the thickness of the Ultra-Thin Glass layer by roughly 50%, a change widely discussed in materials engineering circles and confirmed by teardown analyses. According to independent durability tests cited by JerryRigEverything, this thicker UTG improves impact tolerance and slightly diffuses localized stress when the device is fully opened.

However, thicker UTG does not equate to hardness. The inner screen is still covered by a polymer-based protective layer, primarily to allow folding without fracture. In standardized Mohs hardness testing, scratches begin at level 2 and deepen significantly at level 3. This means fingernails, grains of sand, or even light contact with keys can permanently mark the surface. Corning’s own glass science documentation emphasizes that flexibility and scratch resistance remain fundamentally opposed properties at this thickness range.

| Aspect | Improvement in Z Fold 7 | Remaining Risk |

|---|---|---|

| UTG Thickness | Approximately +50% | Still requires soft top layer |

| Crease Visibility | Reduced under normal viewing | Stress concentration persists |

| Scratch Resistance | Unchanged | Mohs level 2–3 vulnerability |

The crease itself is best understood as a stress-management compromise rather than a cosmetic flaw. Samsung’s water-drop folding geometry increases the bend radius, lowering tensile strain on the UTG according to internal engineering disclosures referenced by GSMArena. This reduces microfracture risk over repeated folds, but it cannot eliminate cyclic fatigue entirely. Materials science research from OLED panel suppliers shows that repeated elastic deformation still accumulates stress at the neutral axis, precisely where the crease forms.

From a real-world usability perspective, the scratch risk is the more immediate concern. Unlike micro-stress, which manifests after years, surface damage can occur within days if users treat the inner display like conventional glass. Samsung’s own guidance warns against pressing the screen with hard objects, and repair cost estimates around 589 dollars underscore how unforgiving mistakes can be.

In short, the Galaxy Z Fold 7 inner display is structurally more resilient than its predecessors, yet materially softer than any traditional smartphone screen. The engineering focus has clearly been on managing fold stress and longevity rather than surface hardness, a trade-off that remains unavoidable with current UTG technology.

What Stress Tests Reveal: JerryRigEverything and Real‑World Abuse

Stress tests often cut through marketing claims, and that is exactly what JerryRigEverything’s teardown-style abuse reveals about the Galaxy Z Fold 7. These tests are not designed to mimic careful ownership but to simulate worst‑case scenarios that expose structural priorities and hidden weaknesses. **What emerges is a device that resists catastrophic failure remarkably well, yet remains vulnerable in very specific, predictable ways.**

In scratch testing, the outer panels protected by Gorilla Glass Victus Ceramic 2 behave as expected for a modern flagship, resisting visible damage until higher Mohs levels. The inner display, however, still shows scratches at level 2, reinforcing that the foldable’s most delicate component has not fundamentally changed despite thicker UTG. According to JerryRigEverything, this means fingernails and small debris remain a real threat during everyday use.

| Test Type | Observed Result | Practical Meaning |

|---|---|---|

| Inner screen scratch | Marks at Mohs level 2 | Soft objects can cause permanent damage |

| Back‑bend force | No structural break | High resistance to pocket‑level accidents |

| Dust exposure | Continues functioning | Short‑term tolerance, not full protection |

The most telling moment comes during the reverse bend test. Unlike earlier foldables that fractured along the hinge line, the Z Fold 7 survives aggressive back‑pressure without snapping. **This strongly suggests that the Advanced Armor Aluminum frame and revised hinge locks are doing real work**, a conclusion echoed by TechRadar’s reporting on repeated folding stress exceeding 200,000 cycles.

Dust testing, however, highlights the gap between mechanical strength and environmental resilience. Even when buried in sand, the hinge does not immediately fail, an outcome that appears impressive on video. Yet teardown analyses referenced by iFixit show fine particles migrating past the nylon brushes over time. The stress test therefore demonstrates tolerance, not immunity, aligning with the IP48 limitation rather than contradicting it.

Finally, heat exposure confirms a known OLED behavior: pixels permanently discolor under direct flame. While extreme, this test underscores that no amount of hinge or frame reinforcement can protect the organic display layer itself. **JerryRigEverything’s abuse ultimately reveals a foldable engineered to survive force, not neglect**, rewarding users who avoid abrasive environments while offering reassurance against sudden physical shocks.

Teardown Insights: Repairability, Adhesives, and Long‑Term Wear

Teardown analyses reveal that the Galaxy Z Fold 7 prioritizes structural integrity and thinness over ease of repair, and this design philosophy becomes immediately clear once the device is opened. According to detailed disassembly work by iFixit and independent repair professionals, the internal layout is densely layered, with components stacked under tight tolerances that leave little room for modular servicing.

The most notable characteristic is Samsung’s extensive reliance on high‑strength adhesives. Both batteries, the inner display assembly, and even sections of the mid‑frame are bonded with aggressive adhesive compounds rather than secured by screws. This approach improves rigidity and contributes to the 8.9 mm folded thickness, but it significantly raises the risk of collateral damage during repairs, especially heat‑assisted battery removal.

| Component | Fixation Method | Repair Impact |

|---|---|---|

| Main battery cells | Industrial adhesive sheets | High risk of deformation during removal |

| Inner display assembly | Multi‑layer adhesive bonding | Replacement often requires full teardown |

| USB‑C port board | Screws plus adhesive gasket | Moderate, but time‑consuming |

Repair specialists frequently point out that adhesives age differently than mechanical fasteners. Materials science research cited by IEEE publications shows that repeated thermal cycles accelerate adhesive embrittlement, particularly in ultra‑thin consumer electronics. In the Z Fold 7, sustained heat from the Snapdragon 8 Elite for Galaxy may gradually weaken bonding agents, increasing the likelihood of back‑panel separation or reduced water resistance over several years.

Long‑term wear is also closely tied to hinge contamination and friction surfaces. Teardown inspections confirm that the Armor Flex Hinge contains multiple moving metal elements shielded by thin covers and internal nylon sweepers. While effective in early use, microscopic abrasion over tens of thousands of folds can polish contact points and subtly alter hinge tension, which some early adopters have already described as a “looser” feel rather than outright failure.

From a repairability scoring perspective, European repairability assessments and iFixit both place the Z Fold 7 in the lower tier of smartphones. This does not indicate fragility, but rather that longevity depends heavily on preventive care. For owners planning multi‑year use, authorized service programs and extended coverage become less optional and more structural to the ownership experience.

Who the Galaxy Z Fold 7 Is Built For and Who Should Think Twice

This device is clearly built for users who see a smartphone as a productivity hub rather than a simple communication tool. If you spend long hours reading documents, reviewing spreadsheets, or multitasking between apps, the Galaxy Z Fold 7 is designed to reward that behavior. **Its 8.9 mm folded thickness, combined with a large internal display, targets professionals and enthusiasts who value portability without giving up screen real estate**. Samsung’s engineering choices show a strong preference for people who primarily use their device indoors, in offices, cafés, or controlled urban environments.

According to Samsung’s own engineering briefings and teardown analyses referenced by iFixit, the Armor Flex Hinge prioritizes precise angle control and long-term mechanical stability. That makes the Fold 7 especially appealing to users who rely on Flex Mode for video calls, note review, or hands-free content consumption. For creators who edit photos, manage social media dashboards, or preview designs on the go, the hinge’s resistance to wobble is a practical advantage that competing gearless designs sometimes struggle to replicate.

| User Profile | Why It Fits | Potential Friction |

|---|---|---|

| Urban professionals | Thin body, strong frame, stable hinge for desk use | Needs careful handling around dust |

| Tech enthusiasts | Cutting-edge materials like Victus Ceramic 2 | High repair costs if damaged |

| Content consumers | Large inner display with improved crease control | Inner screen remains scratch-prone |

At the same time, some users should pause before committing. **If your lifestyle regularly involves sand, fine dust, or rugged outdoor conditions, the IP48 rating deserves serious consideration**. IEC 60529 standards make it clear that IP48 does not equal full dust protection, and independent durability tests by JerryRigEverything have demonstrated how fine particles can still migrate into hinge assemblies over time. This does not mean the device is fragile, but it does mean it is selective about where it thrives.

Another group that should think twice includes users who prefer a worry-free, case-free experience. While the outer glass is among the most crack-resistant materials currently used in smartphones, the inner Ultra-Thin Glass layer remains vulnerable to everyday objects like fingernails or keys. Research shared by Corning highlights the strength of ceramic-infused glass against drops, but it does not change the fundamental softness of foldable display stacks.

Cost sensitivity is also a dividing line. With main display replacements approaching the price of a mid-range phone, analysts cited by GSMArena often point out that ownership of a Fold series device assumes either extended warranty coverage or a higher tolerance for repair risk. **The Galaxy Z Fold 7 is best suited to users who intentionally choose it, understand its limits, and adjust their habits accordingly**.

In short, this is a device for deliberate users rather than careless ones. It rewards those who value thinness, engineering elegance, and multitasking power, but it asks outdoor adventurers, rough-and-tumble users, and anyone seeking absolute peace of mind to reflect carefully before making it their daily companion.

参考文献

- GSMArena:Samsung Galaxy Z Fold7 – Full phone specifications

- Samsung Newsroom:The Breakthroughs Powering Samsung’s Thinnest, Most Refined Foldables

- Corning:Corning Gorilla Glass Victus Ceramic 2 Product Information Sheet

- PhoneArena:Galaxy Z Fold 7 battery less than 4,400 mAh, IP rating also disappoints

- Android Central:How the Pixel 10 Pro Fold achieved an IP68 rating with a new hinge design

- SamMobile:Galaxy Z Fold 7 redefines foldables: 5 reasons it’s Samsung’s best yet